Active fault crossing tunnel seismic reduction joint structure, tunnel structure and construction method

A technology of active faults and construction methods, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as low loose strength of rock mass in fault fracture zones, poor structural continuity, and damage to anti-seepage systems, and achieve energy dissipation The shock absorption is effective and reasonable, the large displacement is reduced, and the effect of direct action is slowed down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a shock-absorbing joint structure for tunnels across active faults, such as Figure 4 with Figure 5 As shown, for the longitudinal section I-I of a fault dislocation part, including the rubber layer I-5, the rubber layer I-5 is set in the shock-absorbing joint, and the rubber layer I-5 is subjected to large deformation, and the seismic energy is consumed through the deformation to improve Circumferential deformation tolerance of cross-fault parts. Rubber layer I-5 longitudinal (with Figure 4 The horizontal direction is longitudinal) located between the concrete I-14 of the first construction section and the concrete I-15 of the subsequent construction section, and the circumferential direction is located between the inner steel plate I-8 of the shock-absorbing joint and the outer steel plate I-9 of the shock-absorbing joint .

[0040] Further, the rubber layer I-5 is connected with the concrete I-14 of the first construction section and the...

Embodiment 2

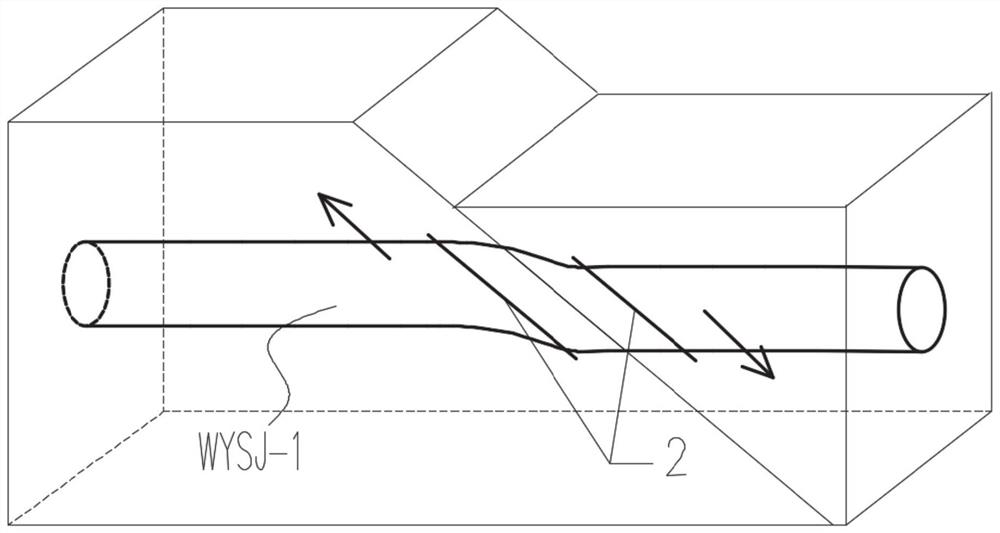

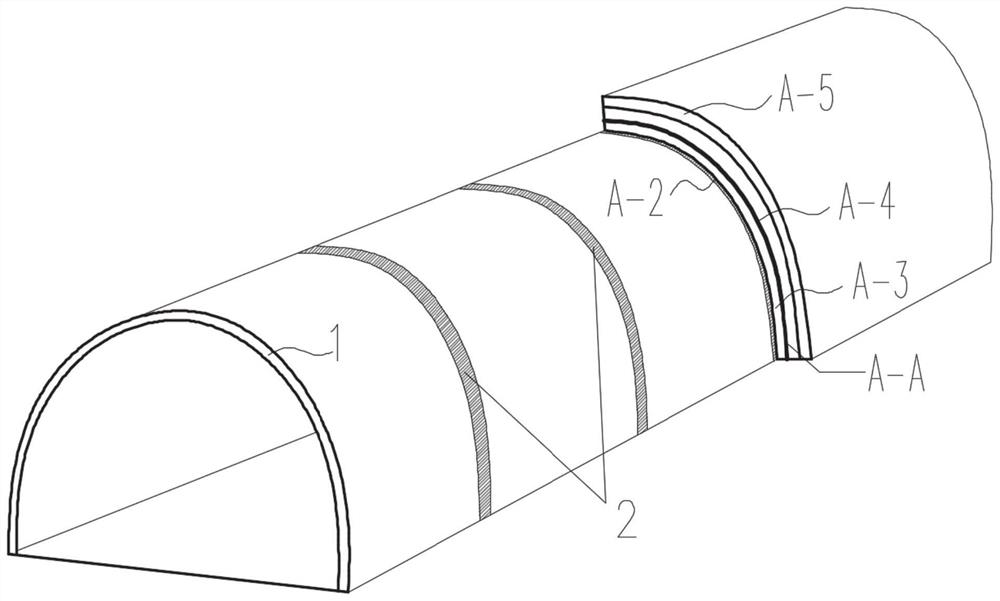

[0051] This embodiment provides a tunnel structure across active faults, taking the tunnel construction section WYSJ-1 as an example, as Figure 1-Figure 3 As shown, it includes the secondary lining layer 1 of the tunnel construction section, and the shock-absorbing layer 2 of the tunnel construction section distributed along the longitudinal interval of the tunnel.

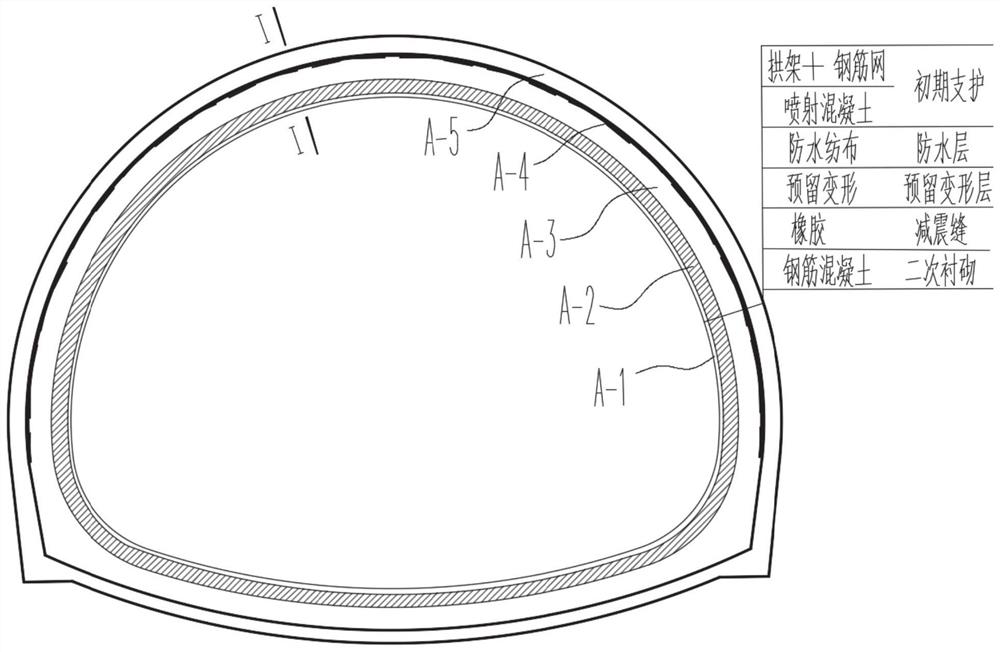

[0052] The fault-crossing part of the tunnel is prone to large displacement and dislocation under the action of an earthquake, which will lead to excessive stress and damage of the tunnel structure or excessive deformation and affect normal use. coming adverse effects. For the cross-section A-A of any fault-crossing part of the tunnel, the secondary lining layer A-1 of the section, the shock-absorbing layer A-2 of the section, the reserved deformation layer A-3 of the section, the waterproof layer A-4 of the section, and the Primary support layer A-5.

[0053] This embodiment adopts the method of shock absorbin...

Embodiment 3

[0059] This embodiment provides a construction method for the construction of a waterproof shock-absorbing joint for a cross-fault tunnel, including:

[0060] S1: Preparatory work: Put the rubber layer I-5, the inner steel plate I-6 in the first construction section, the inner steel plate I-8 in the damping joint, the inner steel plate I-7 in the later construction section, and the outer steel plate I- in the first construction section. 16. The outer steel plate I-9 of the shock-absorbing joint and the outer steel plate I-17 of the post-construction section are treated in advance (including derusting the surface of the steel plate, grinding the outer edges and corners, and painting the surface). Specifically, as follows:

[0061] (1) Advance treatment of rubber layer I-5:

[0062] The surface of the rubber layer I-5 is treated by grinding method. First, the surface is cleaned with methanol, then ground with fine sand, then cleaned with methanol, and dried.

[0063] (2) Steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com