Fuel mixing system for preventing knocking of hydrogen internal combustion engine

A fuel mixing, internal combustion engine technology, applied in the charging system, internal combustion piston engine, combustion engine and other directions, can solve the problem of engine knocking and combustion, and achieve the effect of avoiding knocking phenomenon and improving resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

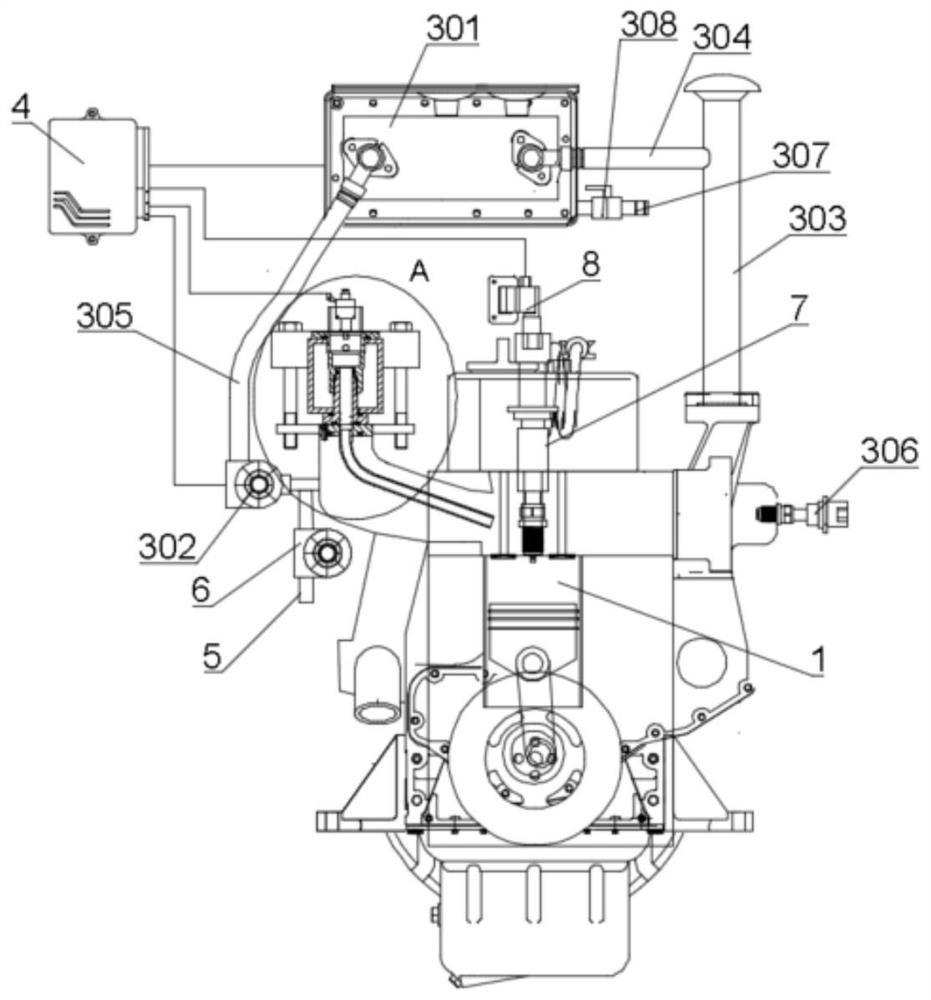

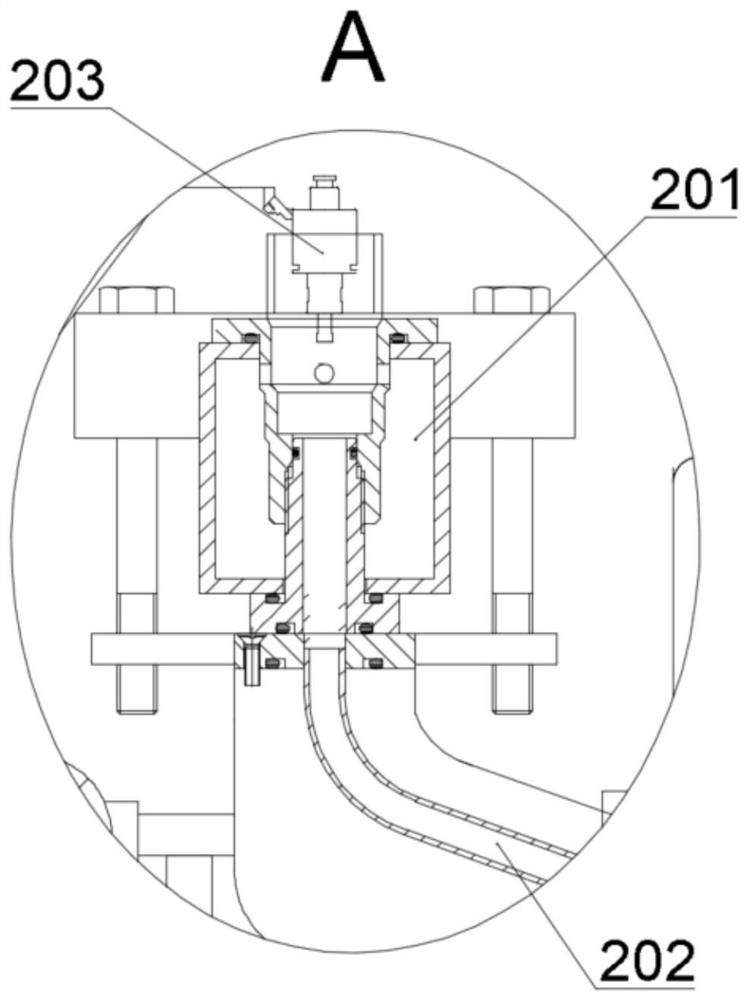

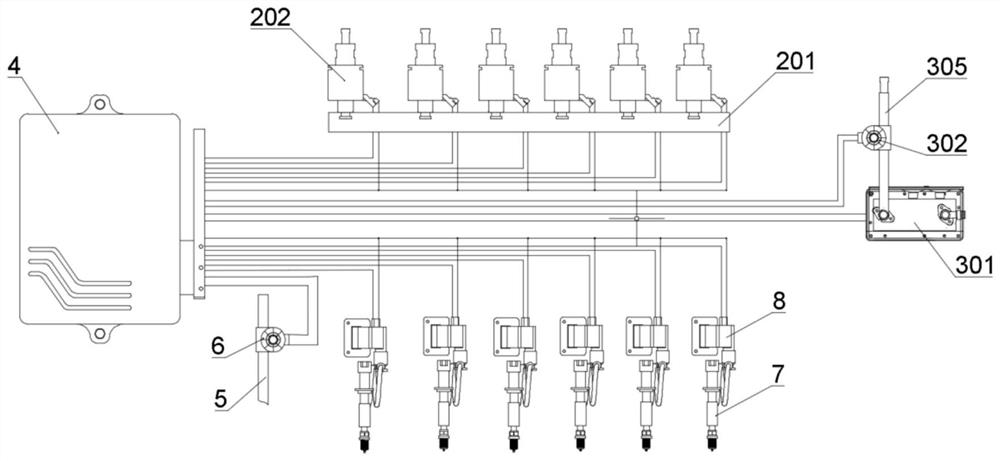

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, to achieve the above object, the technical solution of the present invention is a fuel mixing system for preventing hydrogen internal combustion engine knocking, including cylinder 1, hydrogen intake system, EGR exhaust gas recirculation system and ECU control system 4, hydrogen intake System and EGR exhaust gas recirculation system are connected with ECU control system;

[0023] The hydrogen gas intake system includes a hydrogen gas rail 201 for distributing the amount of hydrogen gas intake. The hydrogen gas gas rail 201 is connected with a hydrogen gas injection pipe 202. The hydrogen gas gas injection pipe 202 is connected with the air inlet of the cylinder. The hydrogen gas gas rail 201 is connected with a hydrogen gas injection valve 203. The hydrogen injection valve is connected to the ECU control system to control the intake of hydrogen. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com