Miniature lithium ion battery and preparation method thereof

A technology of ion battery and micro-lithium, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as shortening battery life and affecting battery performance, and achieve the effects of decreasing expansion coefficient, improving rate performance, and low OI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

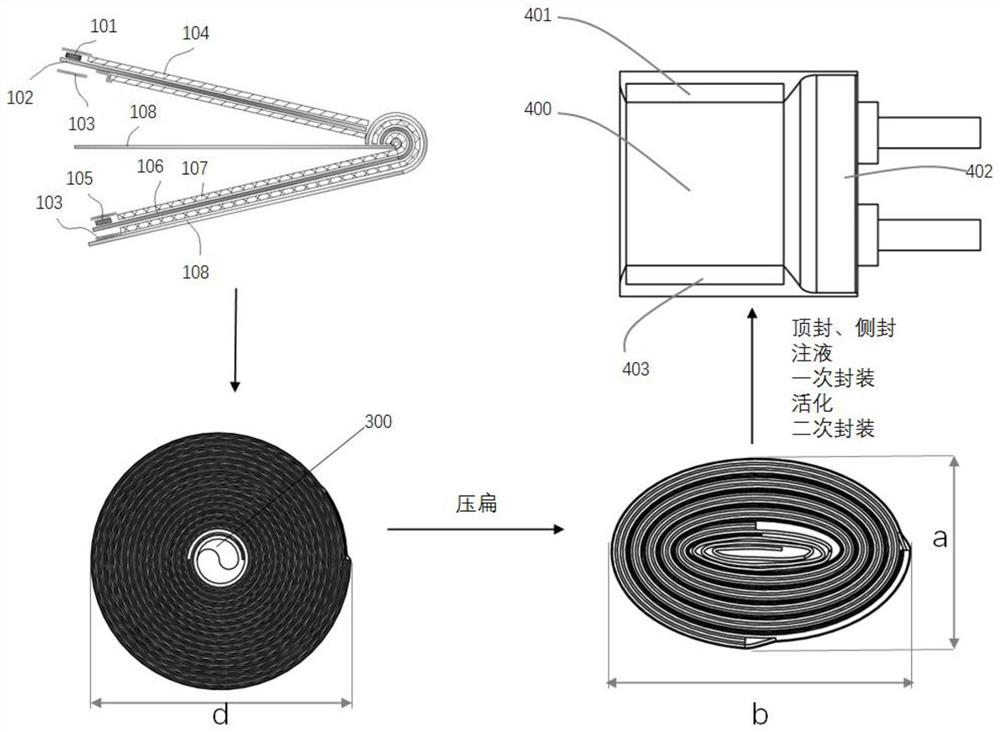

[0138] The present embodiment provides a kind of miniature lithium ion battery and preparation method thereof, specifically comprises the following steps:

[0139] S1. Preparation of positive electrode sheet:

[0140] a. Add lithium cobaltate, conductive carbon black, and PVDF with a D50 particle size of 14 μm to 17 μm in a ratio of 100:1.5:1.5 to a double planetary mixer for pre-mixing for 30 minutes (15 Hz revolution, 4 Hz rotation) to obtain positive electrode solid powder;

[0141] b. Weigh NMP, the quality of NMP is 1 / 3 of the mass of the positive electrode solid powder; by mass, add NMP to the positive electrode solid powder three times: add 8% for the first time, stir for 60min (revolution 15HZ, rotation 4HZ) Add 40% for the second time, stir for 120min (revolution 30HZ, rotation 10HZ); add 52% for the third time, stir for 180min (revolution 30HZ, rotation 35HZ); finally vacuum reverse and stir for 30min for defoaming (revolution 10HZ), Obtain positive electrode slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com