Garlic clove processing equipment integrating cleaning, sorting and slitting

A processing equipment and sorting technology, applied in metal processing, grading, solid separation, etc., can solve problems such as low degree of automation, affecting garlic processing efficiency, and easy failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

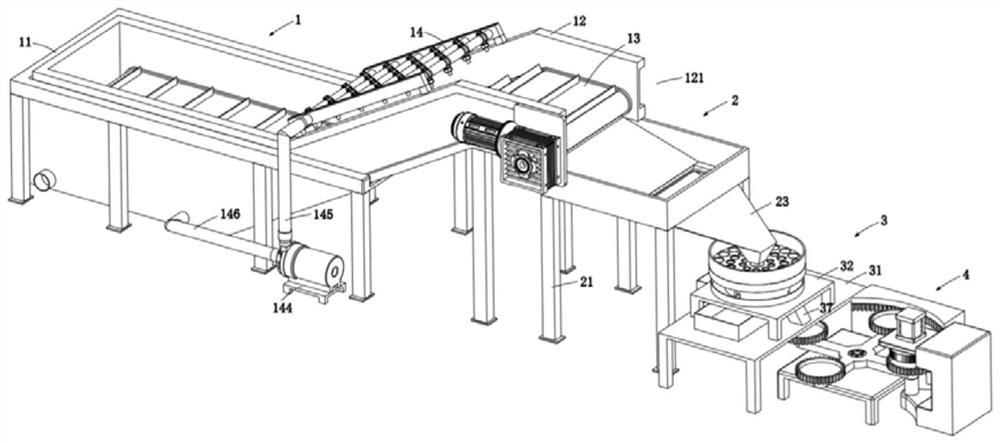

[0045] like Figure 1 to Figure 14 As shown, the invention provides a garlic clove processing equipment integrating cleaning, sorting, and cutting, including:

[0046] The cleaning part 1, the cleaning part 1 includes a water tank 11, a conveying frame 12 arranged in the water tank 11, a conveying assembly 13 arranged at the lower end of the conveying frame 12, and a washing machine arranged on the conveying frame 12 Assembly 14, one end of the transport frame 12 is set as the output end 121;

[0047] The feeding assembly 2, the feeding assembly 2 is located at the output end 121 of the cleaning part 1, and it includes a feeding rack 21, a feeding box 22 arranged on the feeding rack 21, and a feeding box 22 arranged on the upper rack. The feeding pipe 23 at the bottom of the feeding box 22, the bottom surface of the feeding box 22 is provided with a slope that is inclined downward, and the bottom surface of the feeding box 22 is also provided with an upper end that communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com