Mesh plate for boiler denitration elution tower and boiler denitration elution tower

A technology of mesh plate and elution tower, which is applied in the field of boiler flue gas treatment, can solve problems such as ineffective effect, exhaust gas cannot contact with water curtain, and impossibility to be intact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

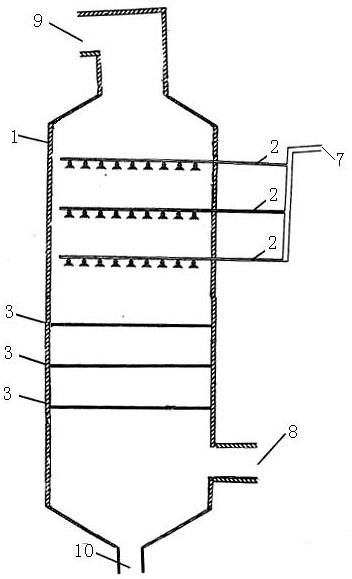

[0019] see figure 1 , the names of parts are as follows: Elution tower body 1 (desulfurization or denitrification), nozzle spray device 2, mesh plate 3, hole 4, upper hole 5, lower hole 6, spiral nozzle spray eluent inlet 7, smoke dust Inlet 8, outlet 9 after dust purification (connected to the chimney), and eluent outlet 10.

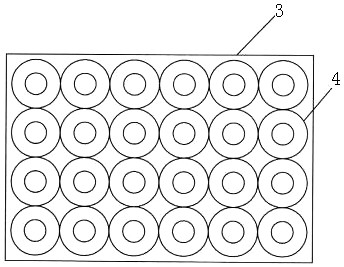

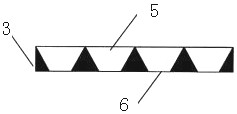

[0020] see figure 2 , 3 , a mesh plate for boiler denitrification and elution tower, which includes a mesh plate 3 with several holes 4, the holes 4 are composed of upper holes 5 and lower holes 6, and the diameter of the upper holes 5 is larger than the diameter of the lower holes 6.

[0021] The holes 4 are inverted trapezoidal, or concave. The distance between the upper hole 5 and the upper hole 5 is almost zero, or close to the arrangement to prevent the eluent from flowing horizontally. The diameter of the lower hole 6 is smaller than the diameter of the upper hole 5 . Not only is the structure of the mesh plate required, but also to reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com