Method for preparing silicon dioxide from graphene oxide waste liquid

A technology of silica and graphene, which is applied in the fields of silica, silica, energy and wastewater treatment, etc., can solve problems such as difficult to produce economic benefits, low removal efficiency, and many impurities in silica, and achieve waste reuse , environmental protection, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

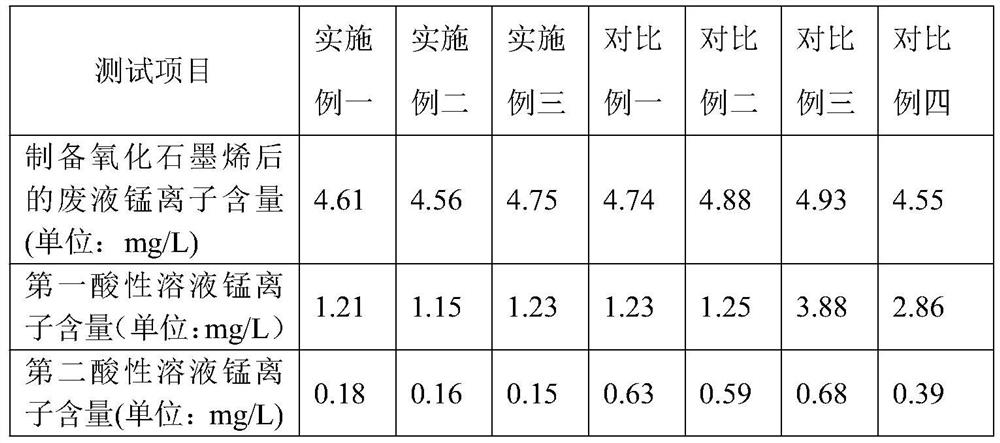

Embodiment 1

[0039] A kind of method that utilizes graphene oxide waste liquid to prepare silicon dioxide, first the waste liquid that prepares graphene oxide is collected and takes by weighing 500g of this waste liquid that prepares graphene oxide, contains potassium ion, manganese ion, Sulfate ion, hydrogen ion, take by weighing the organic chelating agent 5g that prepares according to above-mentioned method and join in this waste liquid, leave standstill 10 minutes after stirring, make this organic chelating agent fully chelate the manganese ion in waste liquid, Then add 8g sherwood oil, stir, leave standstill, now sherwood oil has fused the organic chelating agent that has chelated manganese ion, has formed organic layer, and all the other waste liquids are inorganic layer, utilize separatory funnel to remove organic layer then, The obtained inorganic layer is the first acidic solution. Compared with the original waste liquid, the first acidic solution has removed part of the manganese ...

Embodiment 2

[0042] A kind of method that utilizes graphene oxide waste liquid to prepare silicon dioxide, first the waste liquid that prepares graphene oxide is collected and takes by weighing 500g of this waste liquid that prepares graphene oxide, contains potassium ion, manganese ion, Sulfate ion, hydrogen ion, take by weighing the organic chelating agent 5g that prepares according to above-mentioned method and join in this waste liquid, leave standstill 10 minutes after stirring, make this organic chelating agent fully chelate the manganese ion in waste liquid, Then add 8g sherwood oil, stir, leave standstill, now sherwood oil has fused the organic chelating agent that has chelated manganese ion, has formed organic layer, and all the other waste liquids are inorganic layer, utilize separatory funnel to remove organic layer then, The obtained inorganic layer is the first acidic solution. Compared with the original waste liquid, the first acidic solution has removed part of the manganese ...

Embodiment 3

[0045] A kind of method that utilizes graphene oxide waste liquid to prepare silicon dioxide, first the waste liquid that prepares graphene oxide is collected and takes by weighing 500g of this waste liquid that prepares graphene oxide, contains potassium ion, manganese ion, Sulfate ion, hydrogen ion, take by weighing the organic chelating agent 5g that prepares according to above-mentioned method and join in this waste liquid, leave standstill 10 minutes after stirring, make this organic chelating agent fully chelate the manganese ion in waste liquid, Then add 8g sherwood oil, stir, leave standstill, now sherwood oil has fused the organic chelating agent that has chelated manganese ion, has formed organic layer, and all the other waste liquids are inorganic layer, utilize separatory funnel to remove organic layer then, The obtained inorganic layer is the first acidic solution. Compared with the original waste liquid, the first acidic solution has removed part of the manganese ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com