Frosting etching solution as well as preparation method and use method thereof

A technology of etching solution and frosting, which is applied in the field of frosting etching solution and its preparation, can solve the problems of poor anti-glare effect and visual fatigue of glass cover plates, and achieve the goals of avoiding glare effect, sufficient corrosion ability and optimizing formula components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

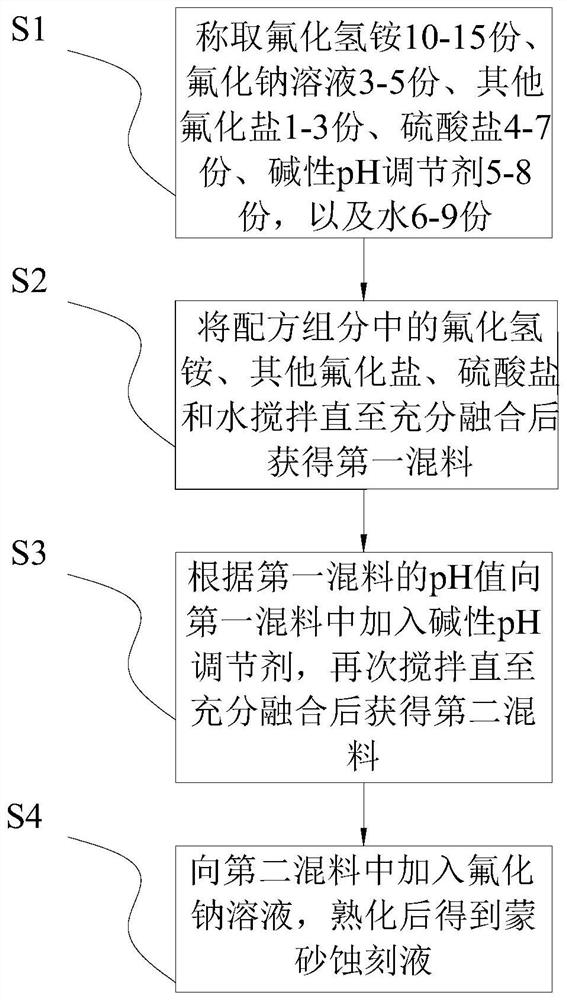

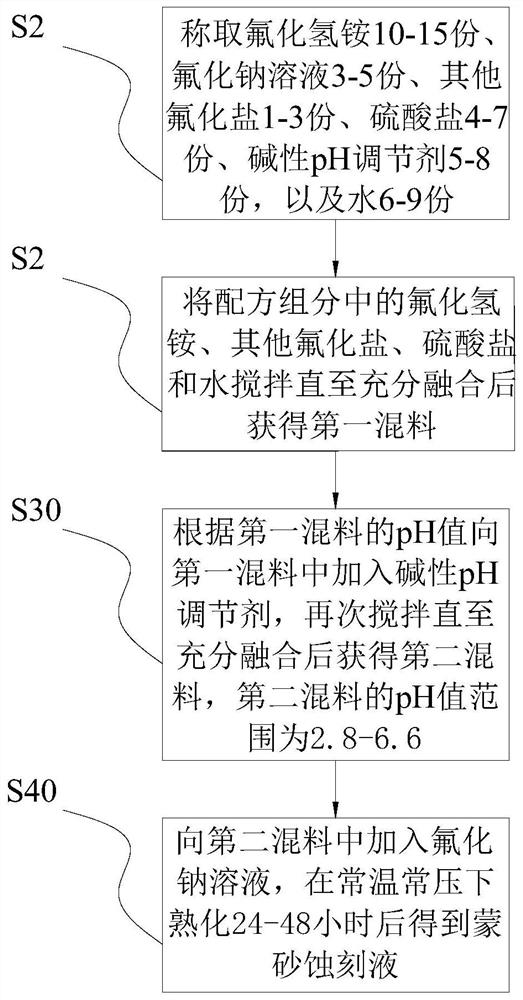

[0049] Also, see figure 1 , an embodiment of the present application also provides a method for preparing frosting etching solution, comprising the following steps:

[0050] S1: Weigh the raw materials of each formula component according to the formula of frosting etchant as mentioned above;

[0051] S2: Stir the ammonium bifluoride, other fluoride salts, sulfates and water in the formula components until fully blended to obtain the first mixed material;

[0052] S3: adding an alkaline pH regulator to the first mixture according to the pH value of the first mixture, stirring again until fully fused to obtain the second mixture;

[0053] S4: adding a sodium fluoride solution to the second mixed material, and aging to obtain a frosting etching solution.

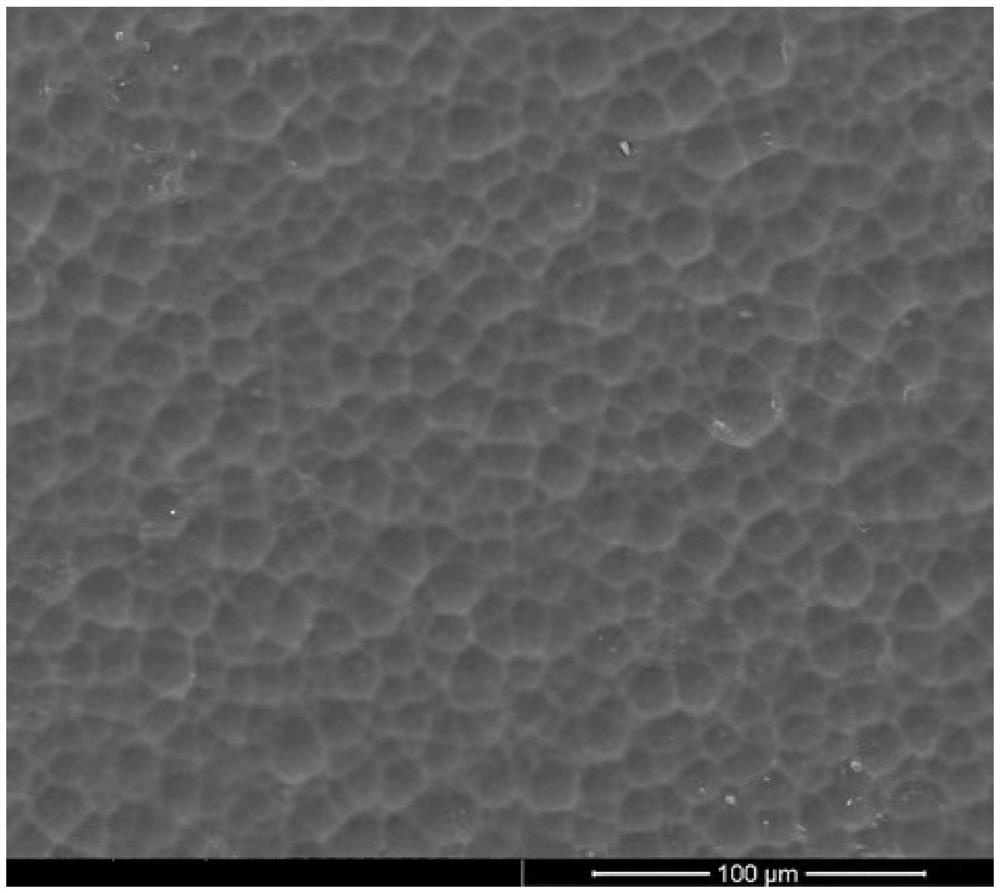

[0054] see Figure 3 to Figure 5 After putting the glass into the frosting etchant provided in this embodiment, under the action of fluoride ions, sulfuric acid and ions, the surface of the glass can be corroded, frosted, an...

Embodiment 2

[0068] Weigh 12.5 parts of ammonium bifluoride, 4 parts of sodium fluoride solution, 2 parts of other fluoride salts, 5.5 parts of sulfate, 6.5 parts of alkaline pH regulator, and 7.5 parts of water; Stir salt, sulfate, and water until fully fused to obtain the first mixture; add an alkaline pH regulator to the first mixture according to the pH value of the first mixture, and stir again until fully fused to obtain the second mixture ; Add sodium fluoride solution to the second mixed material, and obtain frosting etching solution after aging.

[0069] Soak the glass in the frosting etching solution provided in this example for 60s-90s and then take it out. The surface of the obtained glass has a moderate frosting effect. It is measured that the haze of the glass is 30%-40%, and the light transmittance is 65%. % to 75%, the depth range of the microscopic concave spherical surface is 0.8 μm to 0.9 μm, and the width range is 10 μm to 12 μm.

[0070] Moreover, the steel ball drop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com