Porous ceramic composition and preparation method thereof and electronic cigarette atomization core using ceramic composition

A technology of porous ceramics and compositions, applied in the field of porous ceramics, can solve the problems of poor bonding force of metal lines, poor strength of porous ceramics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

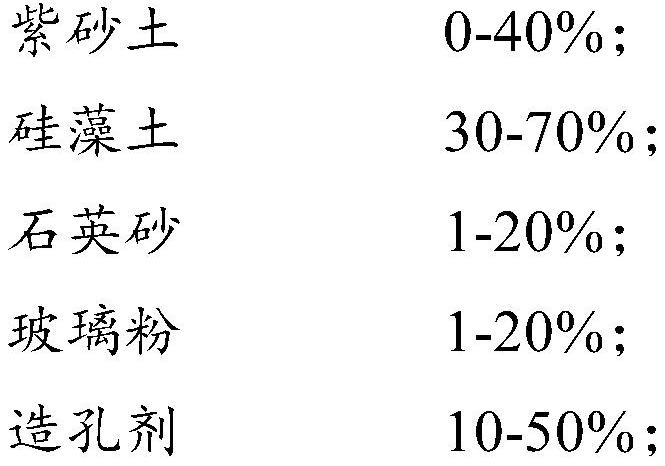

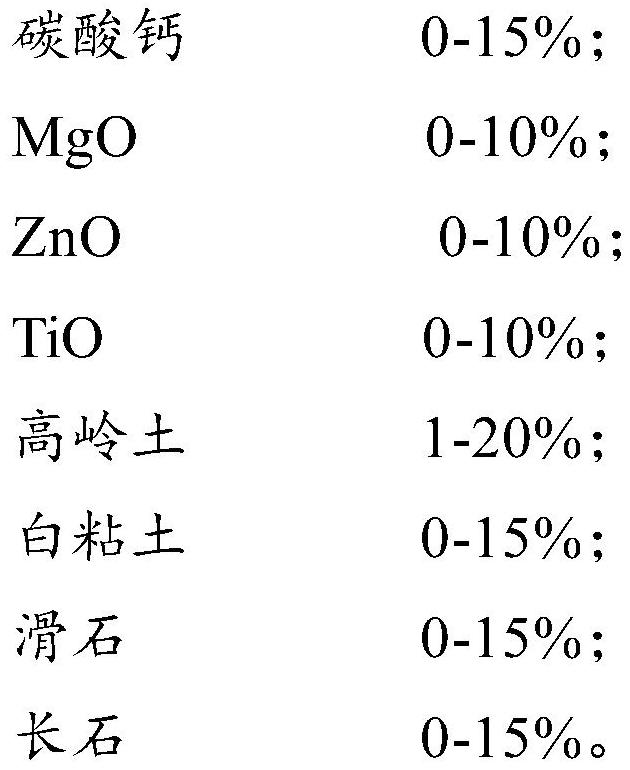

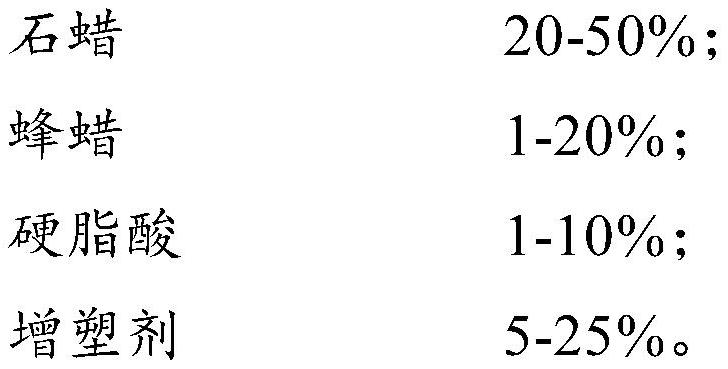

Method used

Image

Examples

preparation example Construction

[0053] The preparation methods of the porous ceramics provided in the embodiments of the present invention can be prepared by various methods well known to those skilled in the art.

[0054] The preparation process of the porous ceramic of the present invention is well known to those skilled in the art, and the typical preparation process is to obtain the porous ceramic through batching, mixing, banburying, injection molding, degreasing and sintering.

[0055] For example, in one embodiment, the porous ceramic preparation method of the present invention comprises the following steps:

[0056] S1, batching according to the ratio of the porous ceramic composition, and mixing the materials;

[0057] S2, putting the solvent into the internal mixer to melt, and after the solvent is completely melted, adding the materials in S1 for mixing and banburying to obtain the mud; the solid content of the mud is 40-70%;

[0058]S3, performing injection molding, degreasing and sintering on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com