Production process of isopropyl myristate

A technology of isopropyl myristate and production process, applied in the field of production technology of isopropyl myristate, can solve problems such as affecting product purity, increasing impurities and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

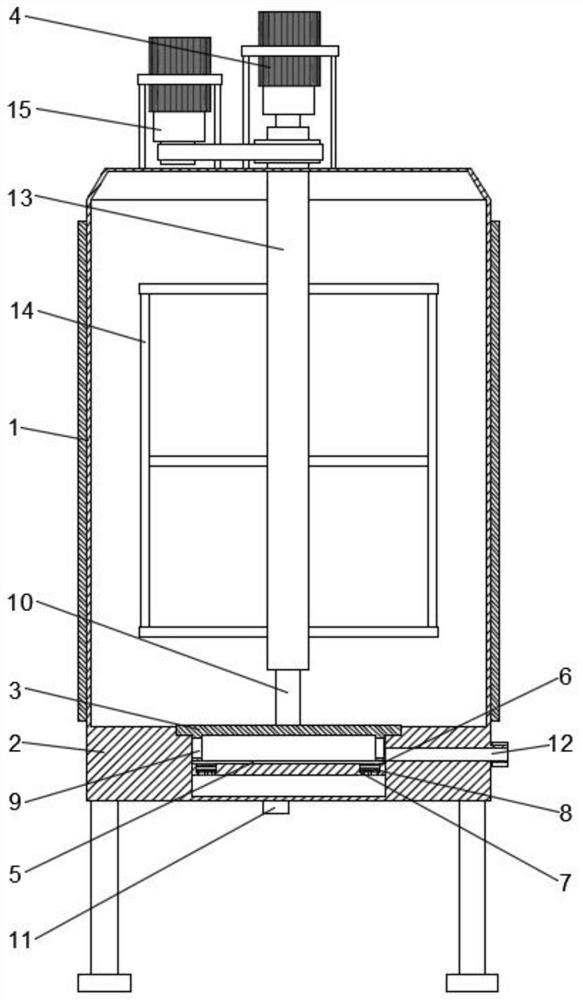

[0024] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

[0025] A kind of production technology of isopropyl myristate, comprises the steps:

[0026] Step 1, put myristic acid and isopropanol in the esterification reaction kettle 1 in turn, heat and stir;

[0027] Step 2. When the temperature in the reaction kettle is heated to 45-55°C, add the catalyst into the esterification reaction kettle and continue heating and stirring to keep the internal temperature of the esterification reaction kettle at 70-85°C (in the actual production process, the technical field Those skilled in the art can determine the specific esterification reaction temperature within the above-mentioned temperature range according to actual needs), and continue to react for 4 to 6 hours (in the actual production process, those skilled in the art can according to actual needs within the above-mentioned reaction time Determine the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com