UV moisture dual-curing silica gel

A dual-curing, silica gel technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of slow initial curing speed of moisture-curing silica gel, corrosion of devices and circuit boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A UV moisture dual-curable silica gel, comprising: vinyl alkoxy-terminated polydimethylsiloxane, mercapto-terminated polydimethylsiloxane, filler, cross-linking agent, catalyst, and photoinitiator.

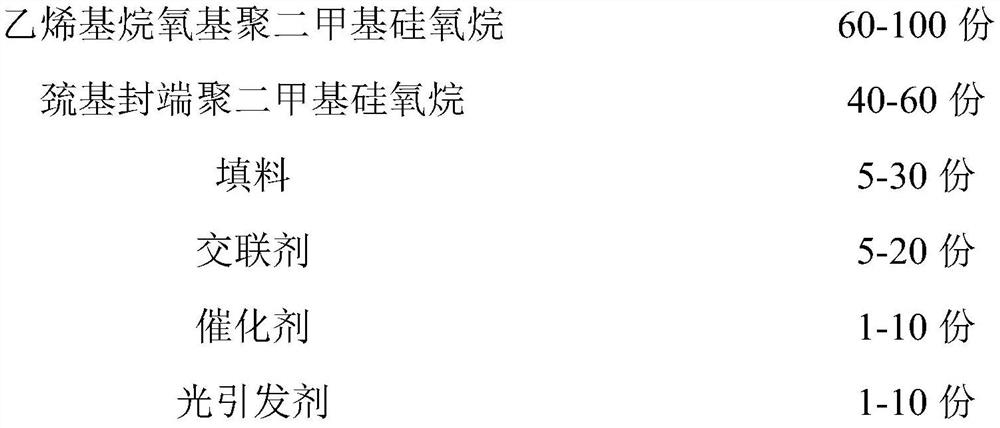

[0046] Concrete composition is as follows by weight part:

[0047]

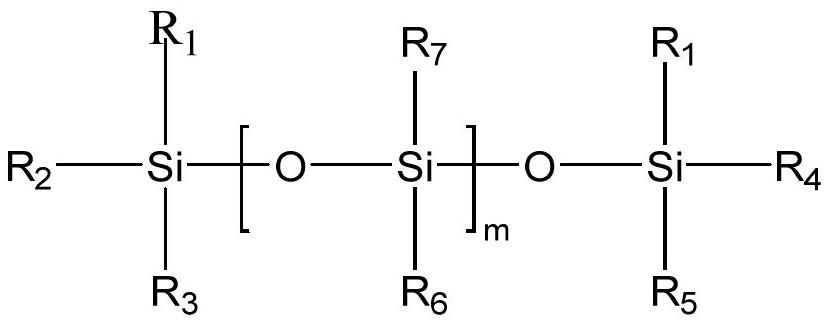

[0048] Wherein the vinylalkoxy-terminated polydimethoxysiloxane in this embodiment contains vinyl and alkoxy bifunctional structure, and the specific structure is as follows:

[0049]

[0050] Among them, R 1 for vinyl, R 2 , R 3 , R 4 , R 5 independently selected from methyl alkoxy, ethyl alkoxy;

[0051] R 6 , R 7 independently selected from methylalkoxy, ethylalkoxy, propylalkoxy, vinylalkoxy, phenylalkoxy, long-chain saturated alkoxy and long-chain unsaturated alkoxy Any group in the group;

[0052] m is an integer of 10-100.

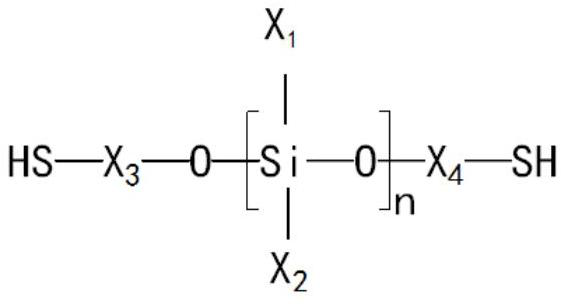

[0053] Wherein the mercapto-terminated polydimethoxysiloxane in the present embodiment has a specific structure as follows:

[0054]

[0055] Among them, X ...

Embodiment 2-14

[0062] The components of Examples 2-14 are the same as those of Example 1, but the proportions are different, see Table 1 for details.

Embodiment 15-22

[0064] The proportioning of Examples 15-22 is the same as that of Example 1, but the components are different, see Table 2 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com