Construction method of plastic sleeve secant pile

A construction method and technology of plastic sleeves, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of poor quality of concrete occlusal parts, water leakage, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

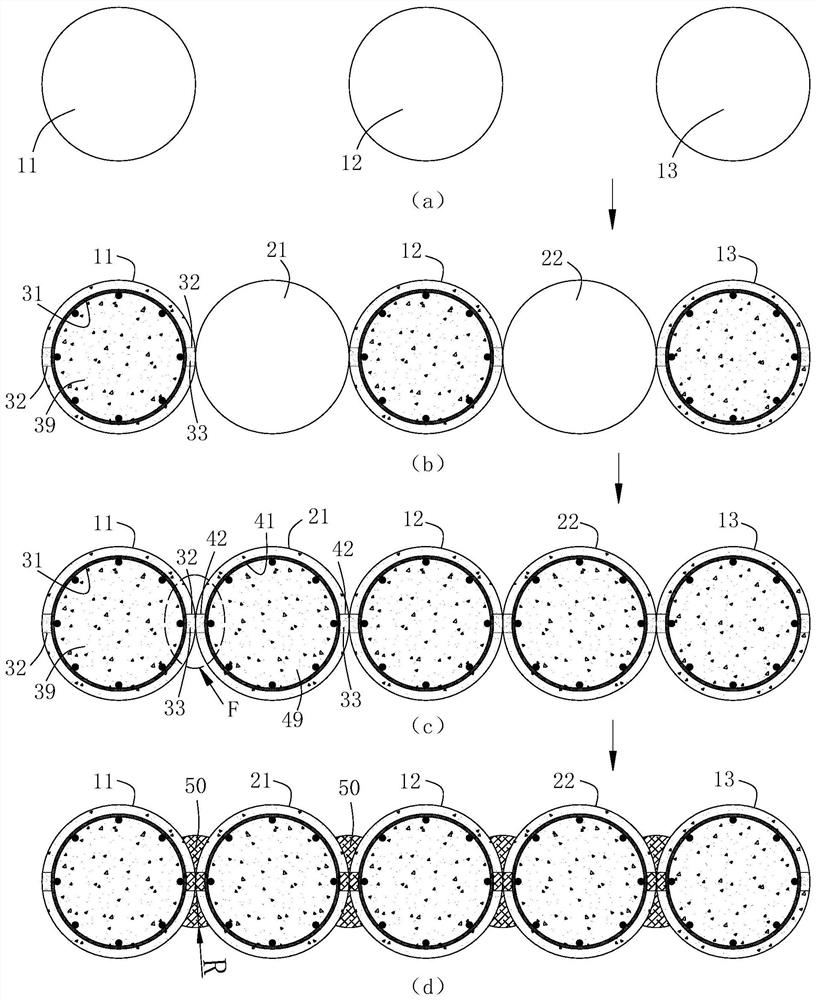

[0035] refer to Figure 1-Figure 3 , a kind of construction method of plastic casing occlusal pile, it comprises the steps:

[0036] (1) Please refer to figure 1 In step a, the first pile hole is constructed at intervals, and the figure 1 3 exemplarily shows three first pile holes, and the three first pile holes are respectively the first pile hole A11, the first pile hole B12 and the first pile hole C13 in sequence.

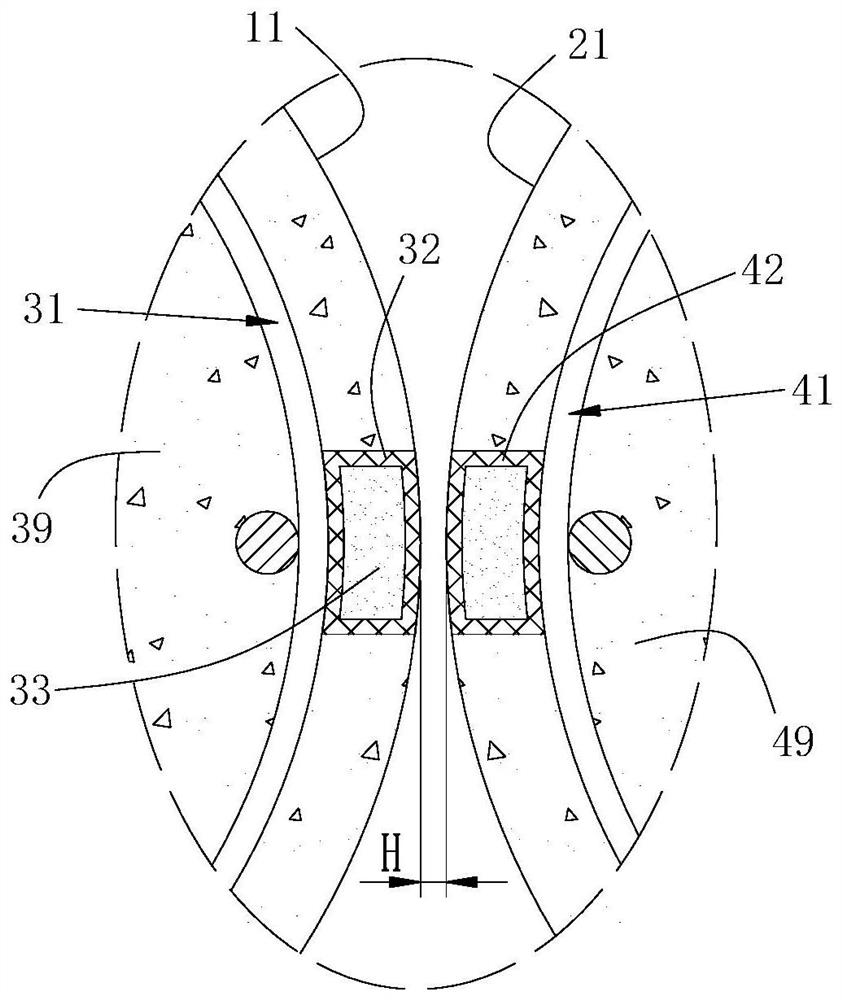

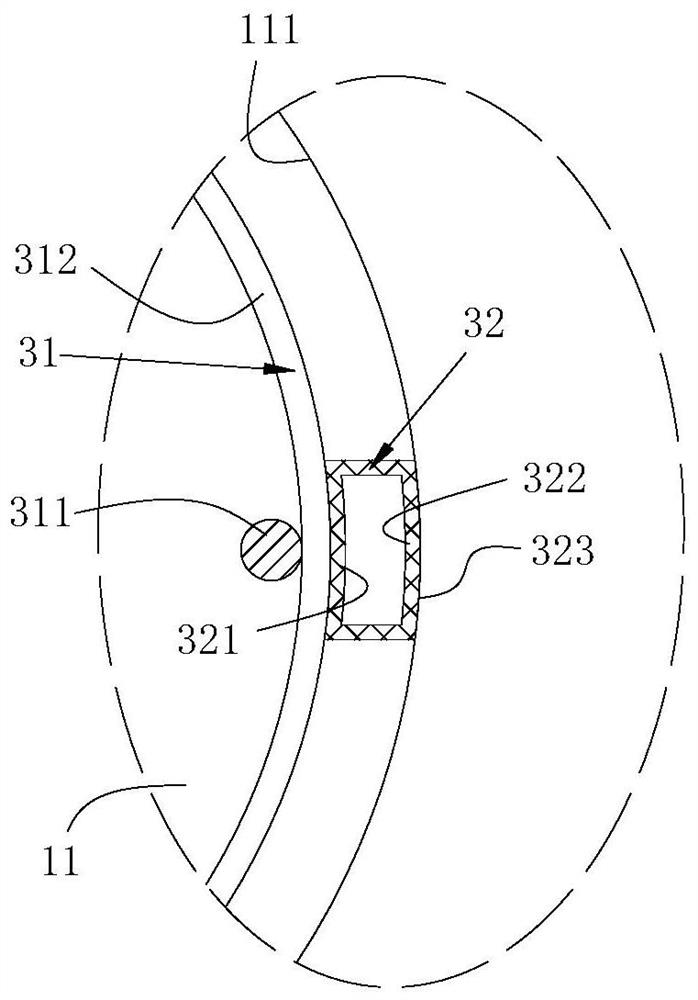

[0037] (2) See figure 1 In step b, lower the first reinforcement cage 31 carrying the first plastic hollow tube 32 into the first pile hole, and the first plastic hollow tube 32 is fixed on the outside of the first reinforcement cage. Sand 33 is poured into the first plastic hollow tube 32 ; then concrete is poured into the first pile hole to form the first pile body 39 .

[0038] The bottom elevation of the first plastic hollow pipe is the same as the bottom elevation of the first reinforcement cage.

[0039] (3) Please continue to readfigure 1 In step b, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com