Vehicle engine oil service life real-time prediction method and device

A real-time prediction and real-time monitoring technology, applied in the direction of measuring devices, lubrication indicating devices, instruments, etc., can solve the problems of high accuracy, shortening, and low implementation cost, and achieve the effects of high accuracy, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

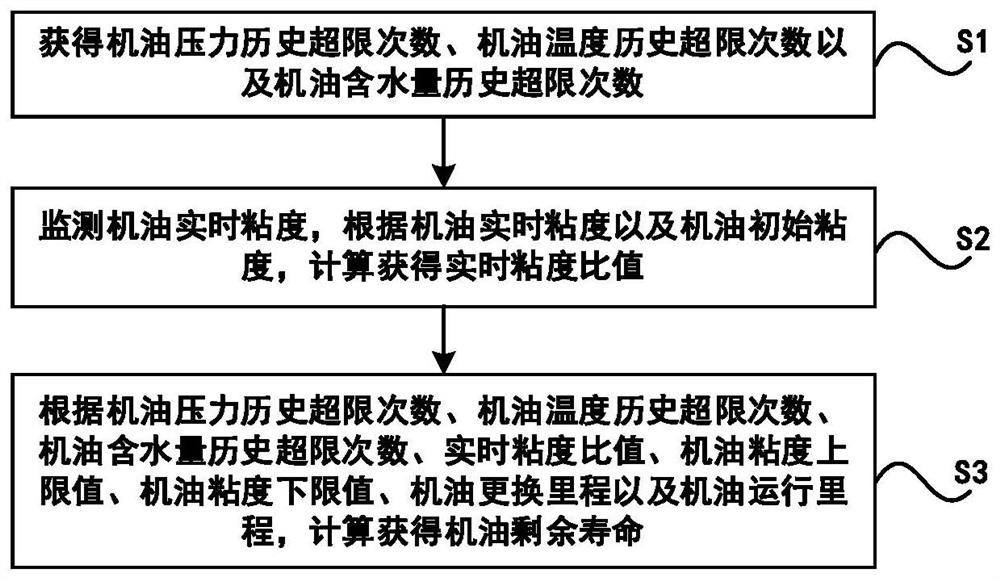

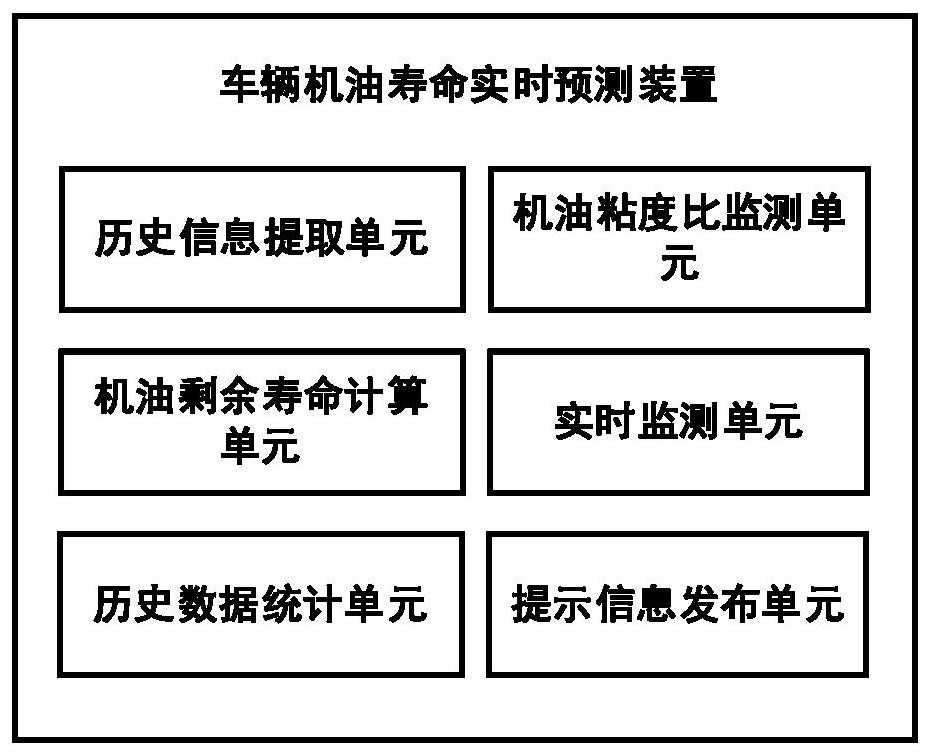

Method used

Image

Examples

Embodiment Construction

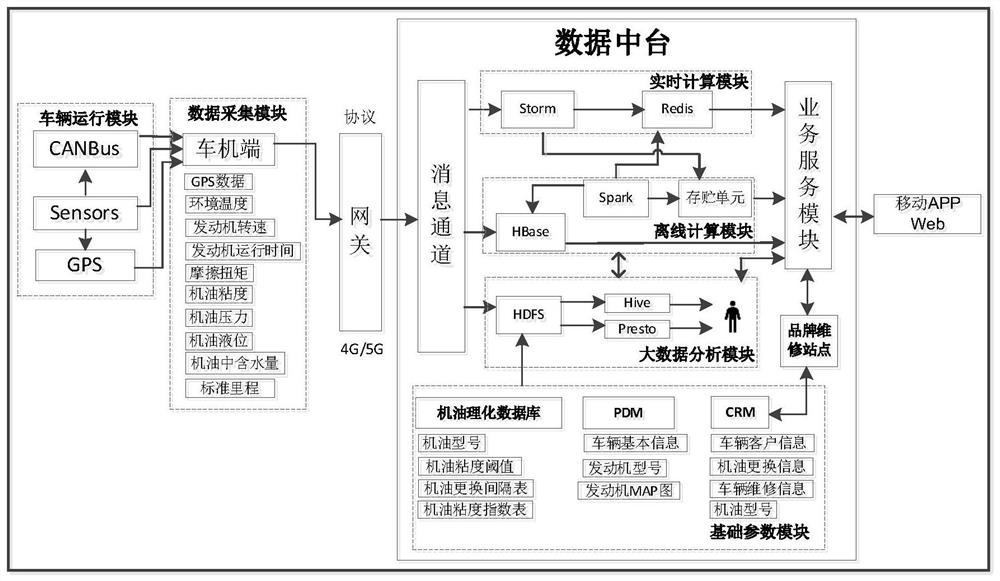

[0047] Explanation of terms:

[0048] CAN Bus, Controller Area Network Bus, serial bus system;

[0049] Sensors, sensor;

[0050] GPS, Global Positioning System, Global Positioning System;

[0051] Storm, a distributed real-time big data processing framework;

[0052] Redis, Remote Dictionary Server, remote dictionary service;

[0053] Spark, a general-purpose parallel framework for Hadoop MapReduce;

[0054] HBase, a distributed, column-oriented open source database;

[0055] HDFS, Hadoop Distributed File System, distributed file system;

[0056] Hive, a data warehouse tool based on Hadoop;

[0057] Presto, a distributed SQL query engine;

[0058] PDM, Product Data Management, product data management;

[0059] CRM, Customer Relationship Management, customer relationship management;

[0060] ECU, Electronic Control Unit, electronic control unit.

[0061] In order to make the purposes, technical solutions and advantages of the embodiments of the present application clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com