Center backdraft type low-nitrogen transformation scheme

A kind of scheme, hollow technology, applied in the field of low-nitrogen retrofit scheme of center back-burning type, can solve the problems of boiler thermal efficiency decline, high exhaust gas temperature, high exhaust gas temperature, etc., to improve heat utilization rate, meet emission requirements, improve The effect of the use of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

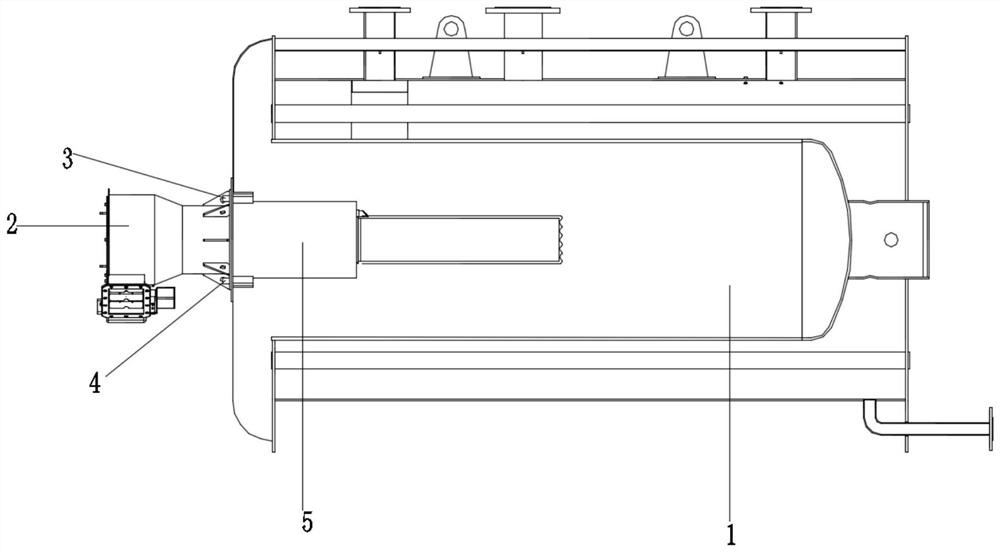

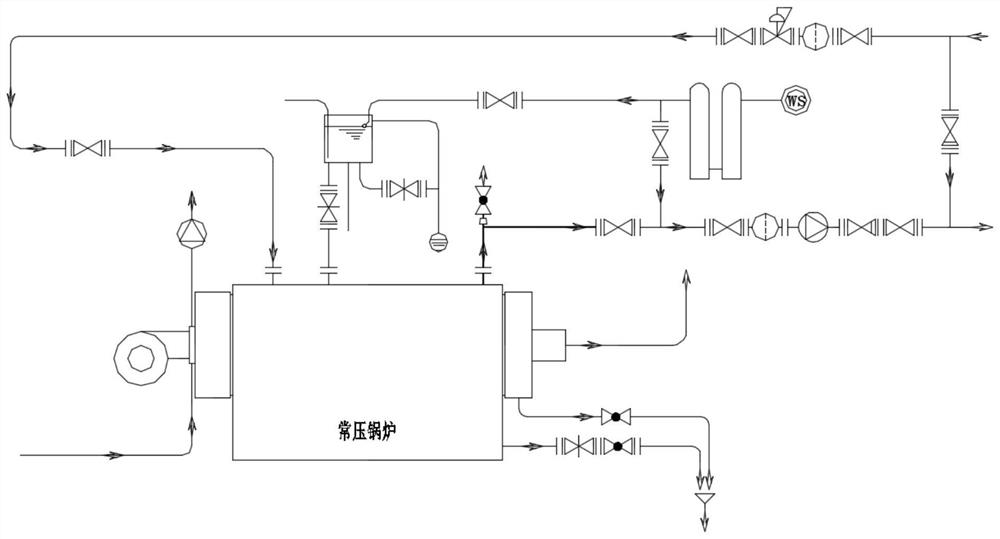

[0024] see image 3 , center backfiring type low-nitrogen transformation plan, place the burner 2 in the normal pressure boiler, the cold water pipe outlet 3 above the burner 2 is connected with the softened water tank of the normal pressure boiler, and a hole is opened in the middle of the bottom of the softened water tank, and The return water of the water-cooling pipe is connected to 4 to form a cycle. The water-cooling pipe absorbs the heat in the combustion chamber to preheat the return water of the boiler to improve the thermal efficiency of the system;

Embodiment 2

[0026] see Figure 4 , center backfiring type low-nitrogen transformation plan, place the burner 2 in the pressure boiler, the water-cooled pipe return water 4 above the burner 2 is connected to the pipe on the lower side of the softened water tank, the pipe is connected to the top of the pressure boiler, and the middle of the pipe Connected to the water outlet 3 of the water-cooled pipe to form a cycle, the water-cooled pipe absorbs the heat in the combustion chamber to preheat the boiler return water to improve the thermal efficiency of the system;

Embodiment 3

[0028] see Figure 5 , center backfiring type low-nitrogen transformation plan, place the burner 2 in the steam boiler, the water outlet 3 above the burner 2 supplies water to the supplementary water tank, and the left side of the bottom of the supplementary water tank is connected to the top of the steam boiler through pipes. The middle is connected with the return water 4 of the water-cooled pipe to form a cycle. The water-cooled pipe absorbs the heat in the combustion chamber to preheat the return water of the boiler to improve the thermal efficiency of the system.

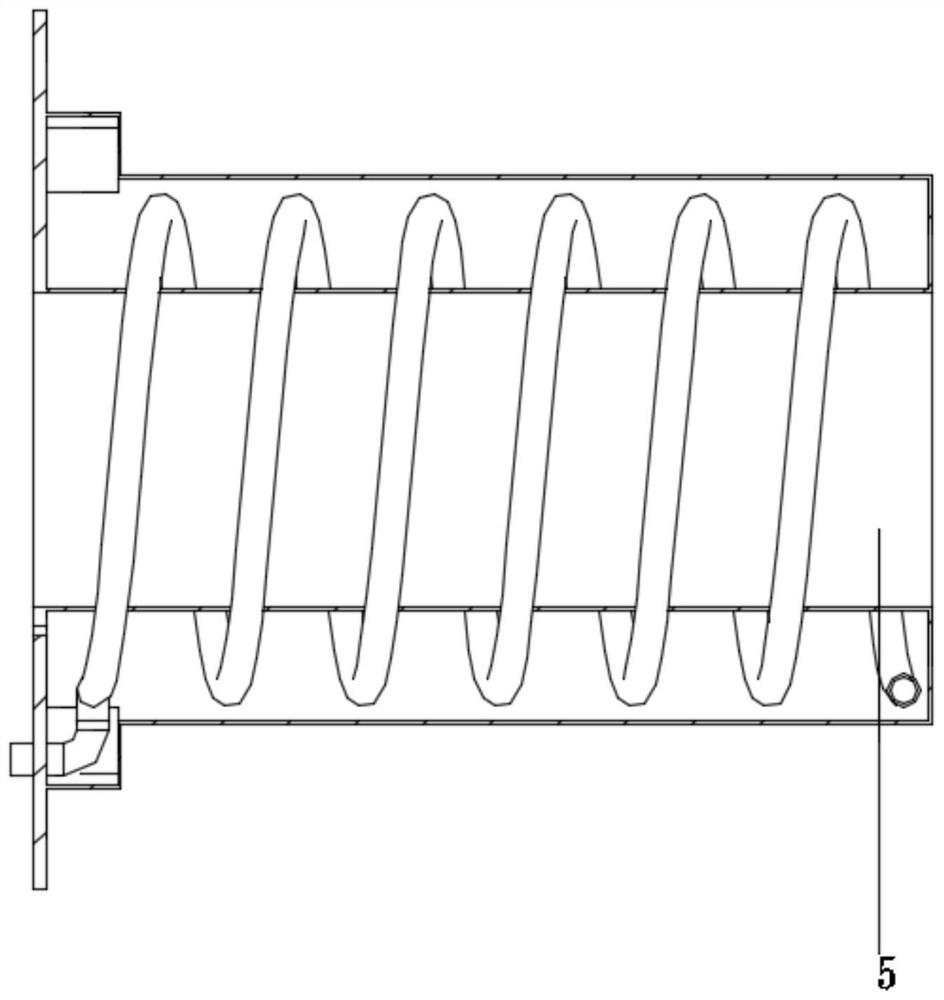

[0029] Working principle: Central backfire type low-nitrogen transformation scheme. Boiler 1 provides low-nitrogen combustion space and performs heat exchange. Gas burns through burner 2 to provide heat for the system. Water-cooled pipe 5 cools down burner 3 to prevent components from overheating and damage. Because the combustion zone avoids the turbulent area of the flow field in the combustion chamber, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com