Component quantitative analysis method, test system and storage medium

A quantitative analysis and testing system technology, applied in the direction of material analysis, material excitation analysis, material analysis through optical means, etc., can solve the analysis difficulties of existing proportions, increase the application threshold of laser-induced breakdown spectroscopy technology, and cannot achieve full Element detection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

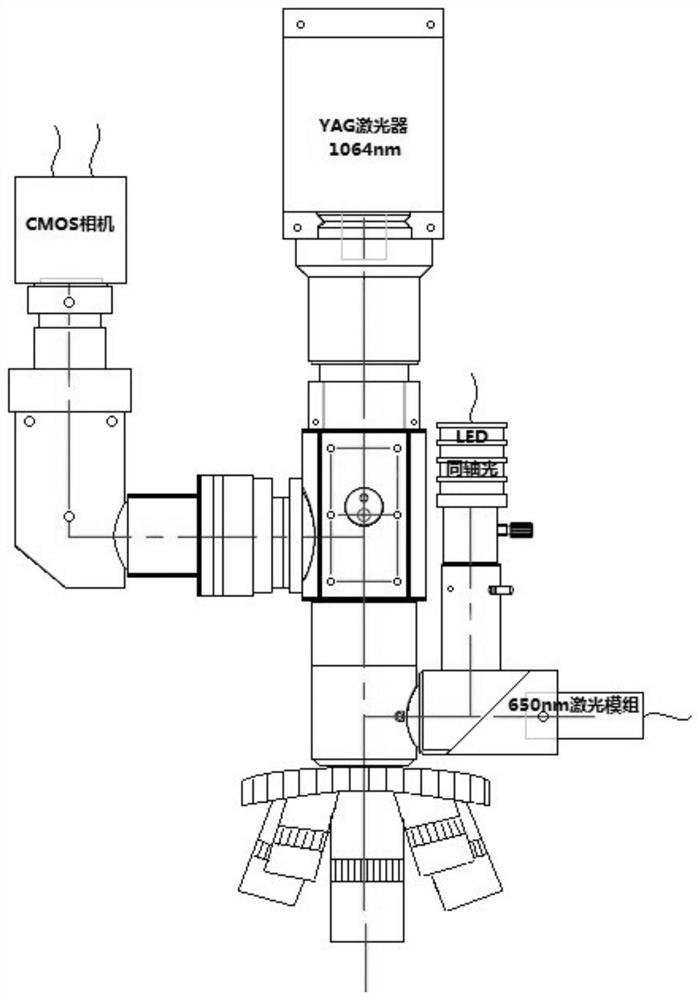

[0037] The present invention will be further described below in conjunction with examples. Such as figure 1 As shown, the test system provided by the embodiment of the present invention is a fully automatic quantitative test system for components based on picosecond laser-induced breakdown spectroscopy. The system is not limited to that described in this embodiment.

[0038] In this embodiment, the test system includes: YAG picosecond laser with 1064nm wavelength (Germany PicoQuantVisUV-1064), CMOS camera (U.S. FLI Kepler KL4040), LED illumination light (U.S. ThorLabs Solis-3C), semiconductor laser with 650nm wavelength (China Huake Optoelectronics DD650), three-axis mobile microscope system (Newport MS-200M-XYZ, USA).

[0039] The three-axis mobile microscope system has a total of four optical path access ports, which are No. 1 optical path access port, No. 2 optical path access port, No. 3 optical path access port and No. 4 optical path access port. The three-axis mobile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com