Process temperature measurement device fabrication techniques and methods of calibration and data interpolation of the same

A technology for measuring parameters and process conditions, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, printed circuits, etc., and can solve problems such as unbearable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Reference will now be made in detail to the disclosed objects illustrated in the accompanying drawings.

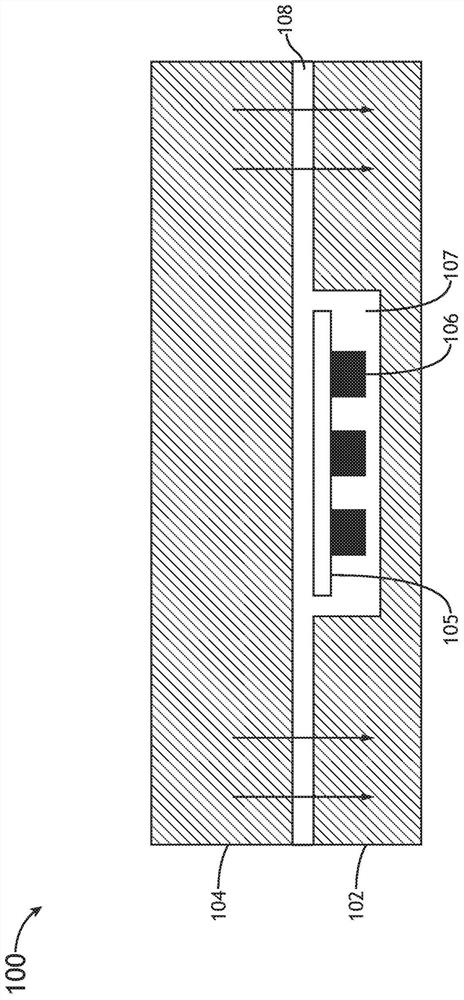

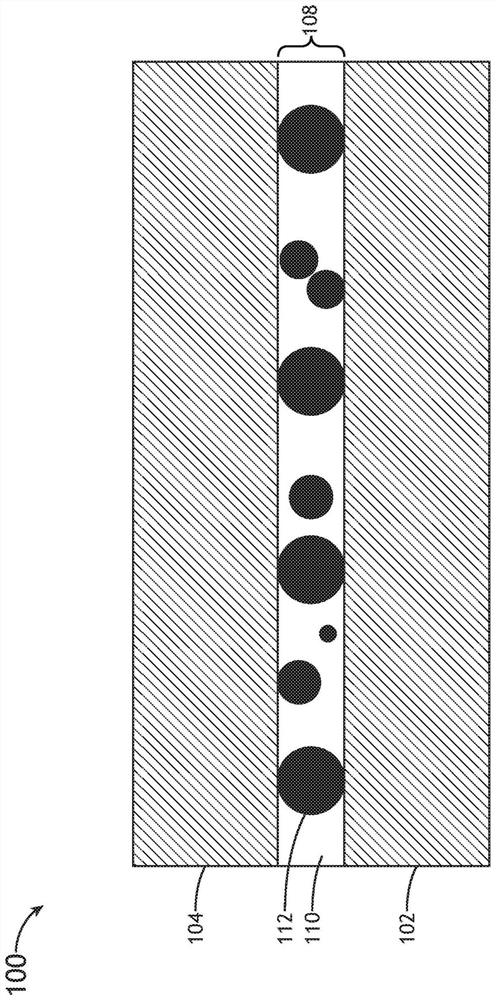

[0024] generally refer to Figures 1A to 5 , shows and describes a system and method for process condition measurement wafer assembly according to one or more embodiments of the present invention.

[0025] Conventional Process Conditions Measurement wafers contain measurement electronics disposed between silicon wafers. The silicon wafer is designed to shield the measurement electronics from the extreme conditions within the process chamber (eg, high RF, high heat flux, high electromagnetic radiation). Silicon wafers within these conventional process condition measurement wafers are typically coupled via one or more discrete ohmic contacts between respective silicon wafers. However, these ohmic contacts result in high current densities in and around the contacts, and possibly high potentials across the process conditions of the measured wafer. In addition, conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com