Preparation method of hydroxypropyl methyl cellulose

A technology of hydroxypropyl methylcellulose and refined cotton is applied in the field of preparation of hydroxypropyl methylcellulose, which can solve the problems affecting the amount of etherifying agent, the degree of etherification reaction, the rise of initial concentration of etherifying agent, and the probability of occurrence of side reactions. Increase and other problems to achieve the effect of reducing the occurrence of side reactions, saving dosage, and avoiding useless consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

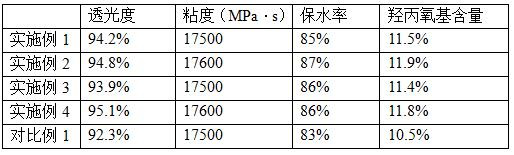

Examples

Embodiment 1

[0033] Alkalinization: Add 100kg of toluene, 40kg of isopropanol, and 20kg of water into the alkali mixing kettle to mix and prepare a binary organic solvent, then add 80kg of sodium hydroxide to the binary organic solvent, dissolve and configure it to form a mixed lye, and mix the The lye is cooled to 25°C for later use. Add 120kg of refined cotton powder with a particle size of 80 meshes into the reaction kettle, then add the prepared mixed lye into the reaction kettle, control the reaction temperature at 20~35°C, and react for 3 hours under stirring to obtain alkalized refined Cotton powder.

[0034] Etherification: prepare 100kg of methyl chloride and 50kg of propylene oxide, take 25kg of propylene oxide and add it to the reaction kettle, react for 40min under the condition of temperature control at 30~50℃, then add 50kg of methyl chloride, and then raise the temperature to 70~90℃ °C for 60 minutes, after the above reaction process is completed, the temperature is lowered...

Embodiment 2

[0037] Alkalinization: Add 80kg of toluene, 50kg of isopropanol, and 20kg of water into the alkali mixing kettle to form a binary organic solvent, then add 60kg of sodium hydroxide to the binary organic solvent, dissolve and prepare a mixed lye, and mix the The lye is cooled to 25°C for later use. Add 100 kg of refined cotton powder with a particle size of 80 mesh into the reaction kettle, then add the prepared mixed lye into the reaction kettle, control the reaction temperature at 20~35°C, and react for 3 hours under stirring to obtain alkalized refined Cotton powder.

[0038]Etherification: prepare 90kg of methyl chloride and 30kg of propylene oxide, take 15kg of propylene oxide and add it to the reaction kettle, react for 30min under the condition of temperature control at 30~50℃, then add 45kg of methyl chloride, and then raise the temperature to 70~90℃ °C for 50 minutes, after the above reaction process is completed, the temperature is lowered to 25 °C, and the reaction ...

Embodiment 3

[0041] Alkalinization: Add 100kg of toluene, 40kg of isopropanol, and 20kg of water into the alkali mixing kettle to mix and prepare a binary organic solvent, then add 80kg of sodium hydroxide to the binary organic solvent, dissolve and configure it to form a mixed lye, and mix the The lye is cooled to 25°C for later use. Add 120kg of refined cotton powder with a particle size of 80 meshes into the reaction kettle, then add the prepared mixed lye into the reaction kettle, control the reaction temperature at 20~35°C, and react for 3 hours under stirring to obtain alkalized refined Cotton powder.

[0042] Etherification: prepare 105kg of methyl chloride and 45kg of propylene oxide, take 15kg of etherification agent and add it to the reaction kettle, react for 20min under the condition of temperature control at 30~50℃, then add 35kg of methyl chloride, and then raise the temperature to 70~90℃ °C for 40 minutes, after the above reaction process is completed, the temperature is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com