Transparent non-woven fabric adhesive tape and preparation method thereof

A technology of non-woven fabrics and tapes, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., which can solve problems such as high cost, affecting the appearance of finished products, and whitening of glue, and achieve low cost and good quality. The effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9 and comparative example 1~10

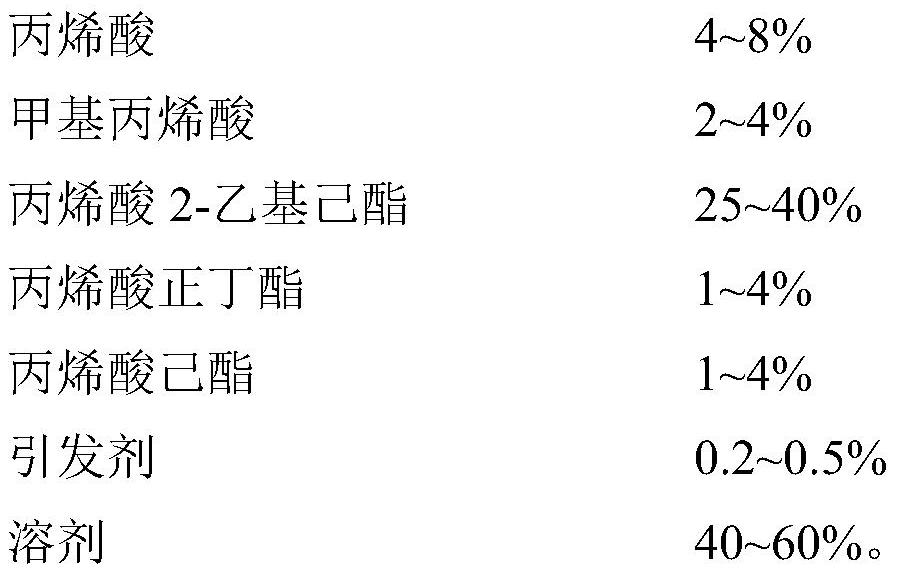

[0035] (1) Add acrylic acid, methacrylic acid, 2-ethylhexyl acrylate, n-butyl acrylate, and hexyl acrylate into the reaction furnace and stir according to mass percentage; heat the mixture in the furnace to 80-90°C, and add dropwise Initiator; after dropping, react at constant temperature for 3-5 hours; add solvent to adjust viscosity to ensure uniform dispersion of solvent; cool down to 45-55°C, discharge to obtain the required acrylate prepolymer;

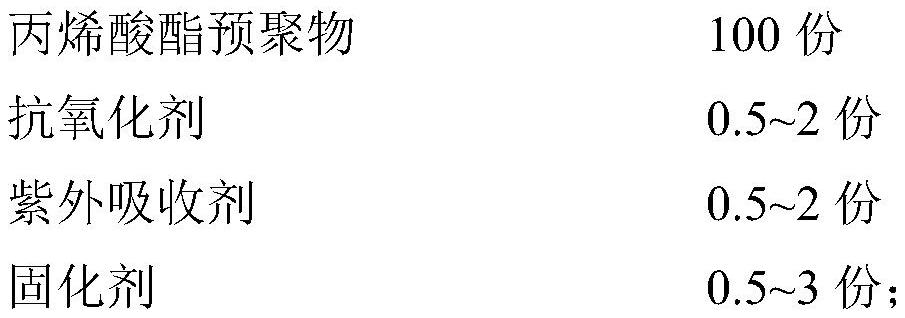

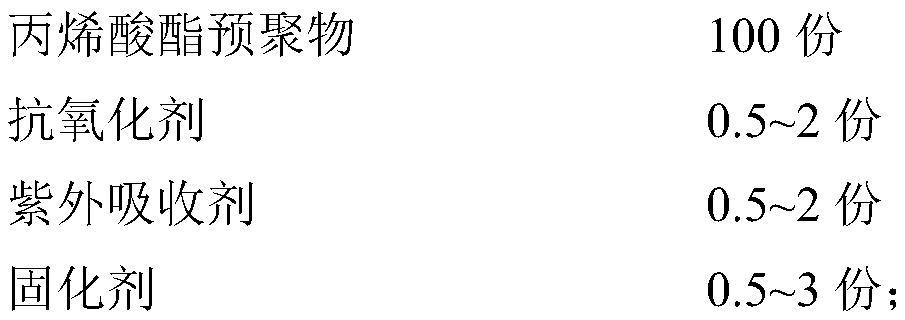

[0036] (2) Mix the acrylate prepolymer prepared above with an antioxidant, an ultraviolet absorber, and a curing agent in parts by mass to obtain an acrylate solvent-based pressure-sensitive adhesive;

[0037] (3) Coat the acrylate solvent-based pressure-sensitive adhesive prepared above evenly on the release paper, and after drying, compound with non-woven fabric and wind up to obtain the first project, the acrylate solvent-based adhesive prepared above The pressure-sensitive adhesive is evenly coated on the release paper, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com