Millet wine and preparation process thereof

A preparation process and a technology for millet wine are applied in the field of winemaking technology to achieve the effects of rich rice fragrance, mellow taste and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention discloses a millet wine, which comprises the following raw materials in parts by weight:

[0035] Main ingredient, the main ingredient includes 99 parts of millet;

[0036] Auxiliary materials include 0.4 parts of rice bran, 0.3 parts of barley and 0.3 parts of peas.

[0037] The preparation technology of a kind of millet wine described above comprises the following processing steps:

[0038] S1: collecting, sorting, cleaning and sterilizing the millet;

[0039] S2: crush the millet processed in S1 to obtain first-grade millet;

[0040] S3: Centrifuge the first-grade millet, remove the broken shells, and obtain the second-grade millet;

[0041] S4: Store the secondary millet in a freezer at -20°C for 48-60 hours;

[0042] S5: Take the second-grade millet frozen in S4 in parts by weight, heat it up to 100°C quickly with a strong fire, and steam it, and the heating time is controlled between 20-30min;

[0043] S6: Take the auxiliary materials in parts b...

Embodiment 2

[0051] The invention discloses a millet wine, which comprises the following raw materials in parts by weight:

[0052] Main ingredient, the main ingredient includes 99 parts of millet;

[0053] Auxiliary materials include 0.5 part of rice bran, 0.2 part of barley and 0.3 part of pea.

[0054] The preparation technology of a kind of millet wine described above comprises the following processing steps:

[0055] S1: collecting, sorting, cleaning and sterilizing the millet;

[0056] S2: crush the millet processed in S1 to obtain first-grade millet;

[0057] S3: Centrifuge the first-grade millet, remove the broken shells, and obtain the second-grade millet;

[0058] S4: Store the secondary millet in a freezer at -20°C for 48-60 hours;

[0059] S5: Take the second-grade millet frozen in S4 in parts by weight, heat it up to 100°C quickly with a strong fire, and steam it, and the heating time is controlled between 20-30min;

[0060] S6: Take the auxiliary materials in parts by we...

Embodiment 3

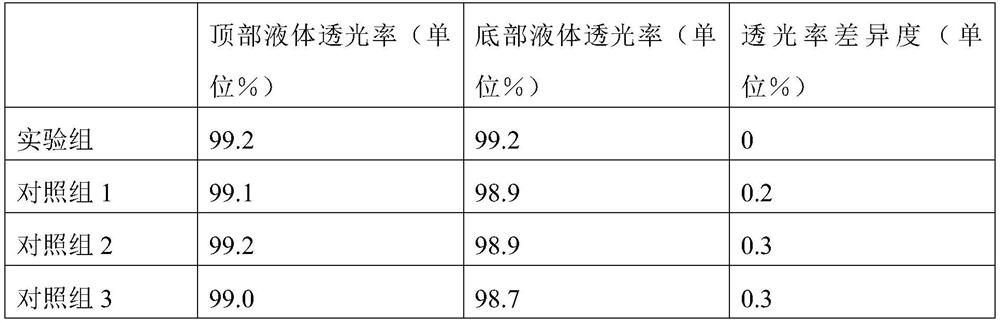

[0069] In the preparation process of the present invention, S4 process is to the influence experiment of finished product:

[0070] Experimental group: 1000kg of finished millet wine prepared according to the complete process provided by the invention;

[0071] Control group: 1000kg of finished millet wine prepared by removing process S4;

[0072] Experimental method 1: Take 100g of millet wine in the experimental group for total acid measurement;

[0073] The millet wine finished product of control group is taken 100g and carries out total acid measurement;

[0074]Experimental data results: the total acid of the experimental group is 0.72g, and the total acid of the control group is 0.63g;

[0075] The results showed that the S4 process could effectively increase the total acid content in millet wine.

[0076] Experimental method 2: Take 100g of the millet wine in the experimental group to measure the total ester;

[0077] The millet wine finished product of control grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com