Method for increasing yield of transglutaminase produced by fermentation

A technology of transglutaminase and production, which is applied in the field of bioengineering and can solve problems such as disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

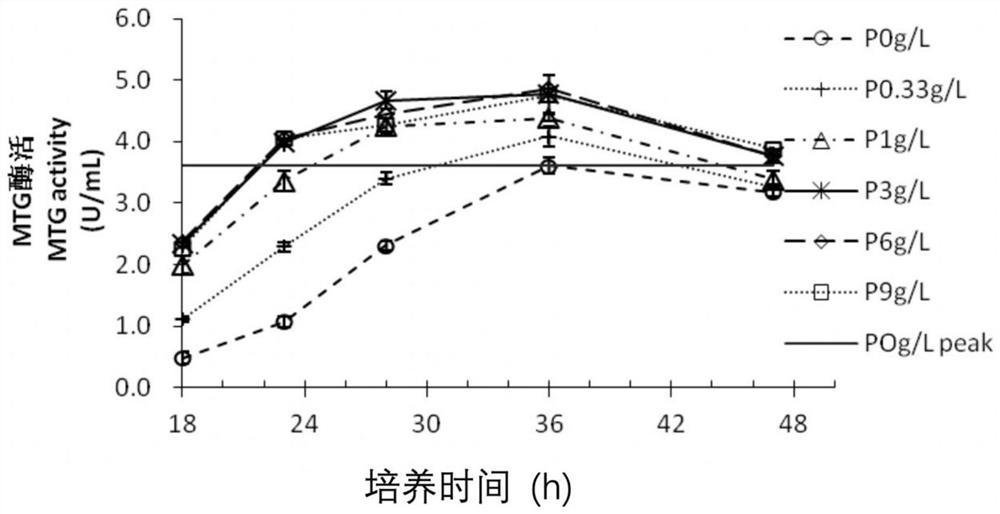

[0041] 0, 0.33, 1, 3, 6, 9 g / L soybean polysaccharides were added to the fermentation medium, and samples were taken at 18, 23, 28, 36, and 47 hours after inoculation and fermentation to determine the MTG enzyme activity in the supernatant of the fermentation broth.

[0042] MTG results such as figure 1 shown. At 23 hours of fermentation, the MTG levels in the groups added with 3, 6, and 9 g / L soybean polysaccharides were significantly higher than the highest levels at 36 hours in the control group (soybean polysaccharide concentration was 0) (P values were 0.0175, 0.0003, and 0.0010, respectively) When fermented to 28h, there was no significant difference in the MTG level of adding 0.33g / L soybean polysaccharide group and matched group, while adding MTG level in the 1g / L soybean polysaccharide group was significantly higher than the highest level when fermented to 36h in the control group ( P value is 0.0071). That is, the MTG enzyme activity of the MTG level in the soybe...

Embodiment 2

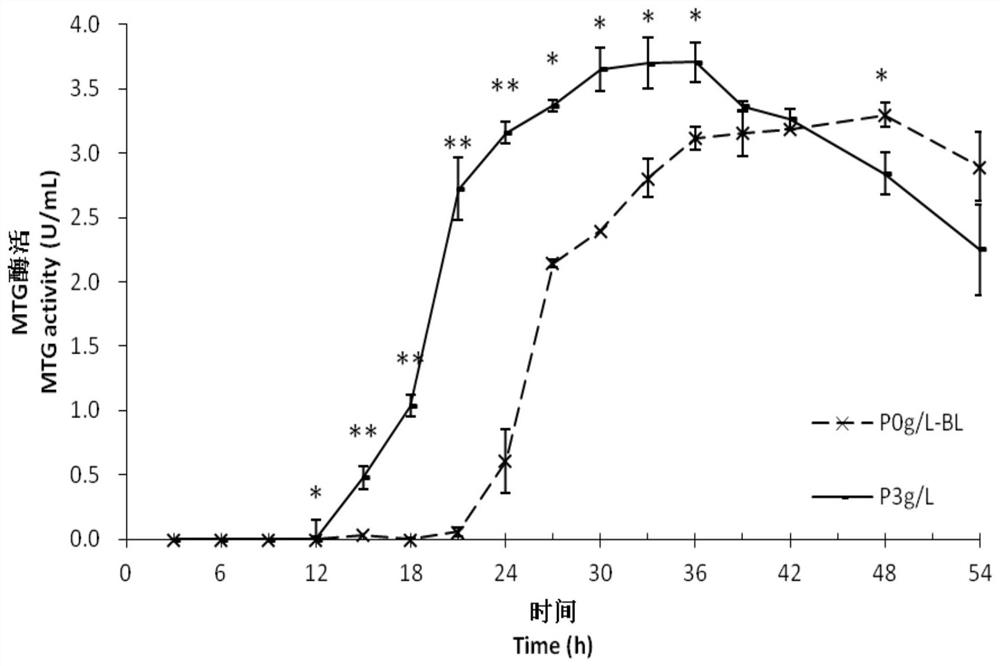

[0044] 0 and 3 g / L soybean polysaccharides were respectively added to the fermentation medium for inoculation and fermentation. The MTG enzyme activity in the supernatant of the 3-54h fermentation broth was measured. MTG enzyme activity as figure 2 shown. Soybean polysaccharide (3g / L) increased the maximum enzyme activity of MTG by 11%, and the maximum enzyme production time was advanced from 48h to before 30h.

Embodiment 3

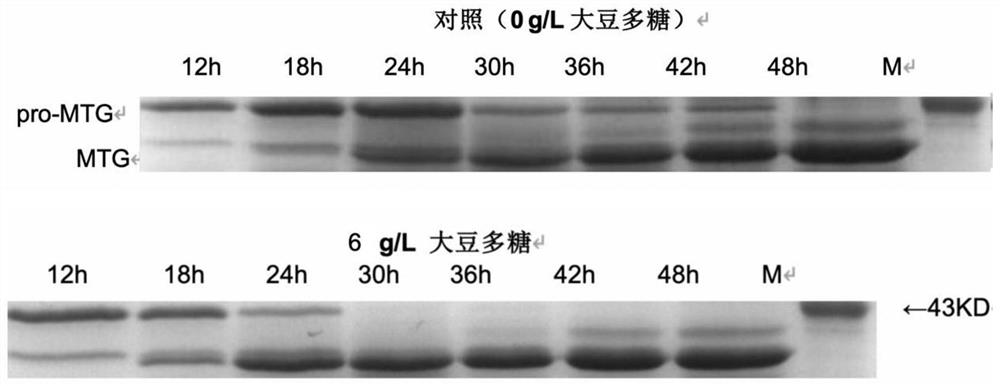

[0046] 0 and 6 g / L soybean polysaccharides were respectively added to the fermentation medium for inoculation and fermentation. Samples were taken every 6 hours from 12h to 48h, and the MTG enzyme activity in the supernatant of the fermentation broth was measured and analyzed by SDS-PAGE gel electrophoresis. MTG enzyme activity is shown in Table 1. The addition of 6g / L soybean polysaccharides advanced the production time of MTG and increased the maximum enzyme activity of MTG by 10.7% (0g / L, 48h; 3g / L, 42h).

[0047] SDS-PAGE electrophoresis results such as image 3 shown. Soybean polysaccharides affected the shearing time of MTG precursor (pro-MTG) in the culture medium. In the control culture medium, a small amount of pro-MTG still remained in the fermentation broth until 42h, while adding 6g / L soybean polysaccharides fermented to At 24h, the residual amount of pro-MTG was very small, and at 30h, it could be completely secreted and matured by shearing immediately. This f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com