Large-volume concrete comprehensive curing system

A technology of mass concrete and curing system, which is applied in the processing of building materials, construction, infrastructure engineering, etc., can solve the problems of waste of water resources, loss of cooling water, complicated operation, etc., so as to reduce workload and achieve cooling effect. Good and water-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

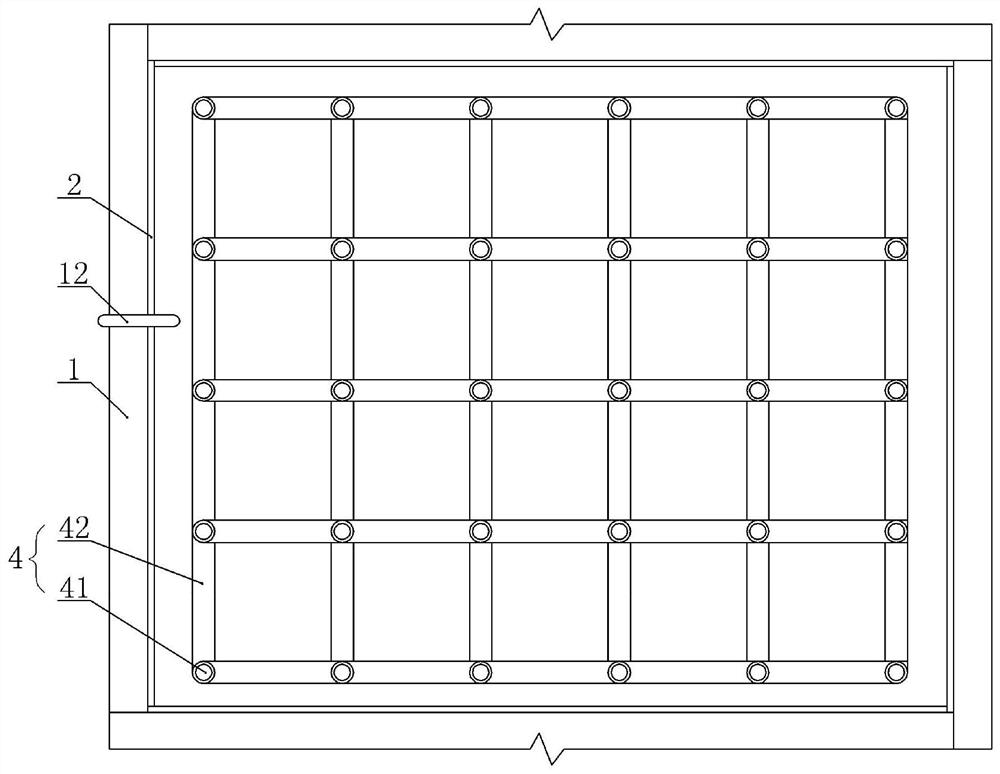

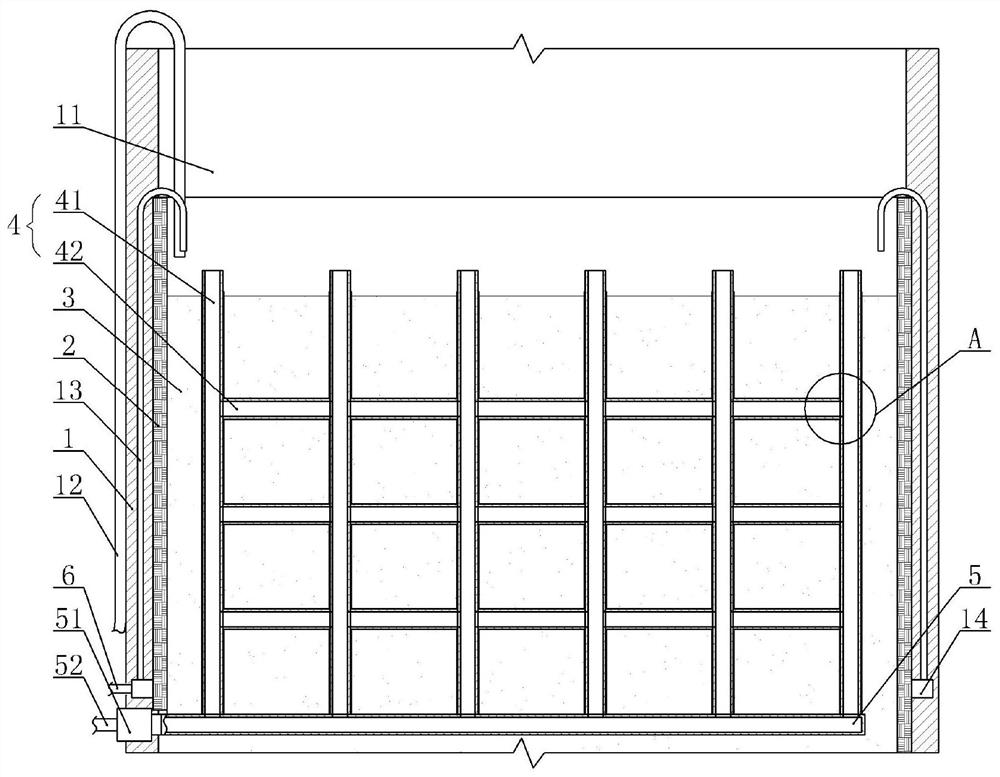

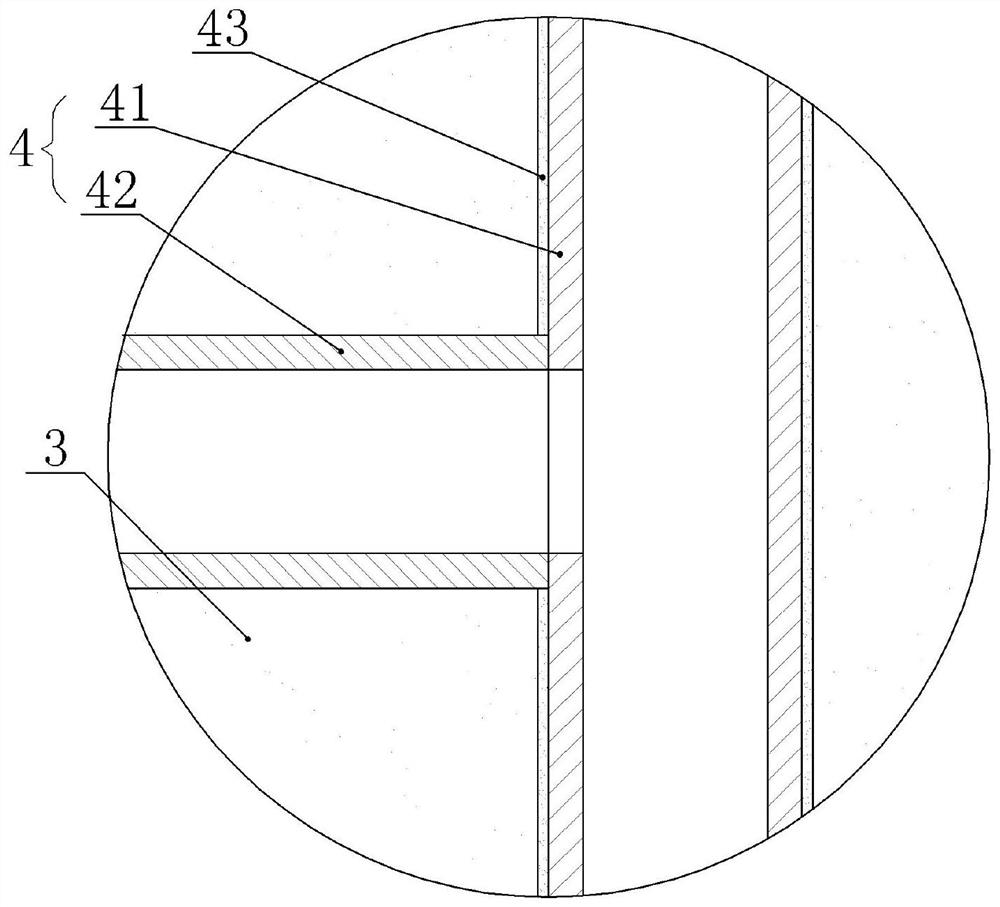

[0025] A comprehensive curing system for mass concrete, such as figure 2 and image 3 As shown, it includes a cooling unit and a maintenance unit. The maintenance unit includes a water storage baffle 1, an air intake pipe 6, an air intake and a plurality of water seepage plates 2. The water storage baffle 1 is ring-shaped, and the water storage baffle 1 is set on The outer side of the concrete 3 and the upper end of the water storage baffle 1 is higher than the concrete 3, and the water storage baffle 1 and the top of the concrete 3 form a reservoir 11. In actual implementation, as figure 1 As shown, the water storage baffle 1 may include multiple panels, and adjacent panels may be connected by fasteners such as bolts. During installation, multiple panels may be installed one by one to reduce installation difficulty. Another example figure 2 and image 3 As shown, the inner wall of each side wall of the water storage baffle 1 is provided with a groove with an opening faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com