Sub-freezing method of frozen flour product

A freezing method and technology of frozen noodles, which are applied in food ingredients as antimicrobial preservation, food preservation, food science, etc., and can solve problems affecting product appearance and internal quality, reducing economic benefits, unfavorable product market promotion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

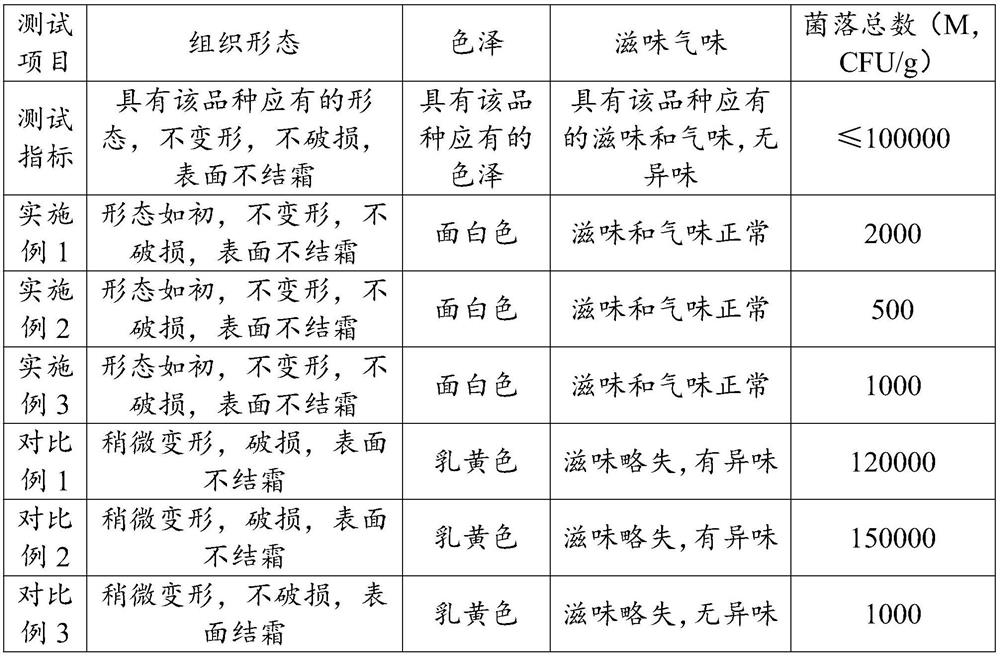

Examples

Embodiment 1

[0032] The sub-freezing method of frozen flour products specifically comprises the following steps:

[0033] (1) Wrap the frozen noodle product with one deck polyethylene cling film, obtain the frozen noodle product after wrapping;

[0034] (2) Heat-shock the wrapped frozen noodles at 40°C for 10 minutes to obtain frozen noodles after the heat-shock treatment;

[0035] (3) Precooling the frozen noodle products after heat shock treatment at 0° C. for 6 hours to obtain the frozen noodle products after precooling;

[0036] (4) Store the precooled frozen noodle products in an environment with a temperature of -2°C and a humidity of 70%.

Embodiment 2

[0038] The sub-freezing method of frozen flour products specifically comprises the following steps:

[0039] (1) Wrapping the frozen noodle product with one deck of polyvinylidene chloride preservative film to obtain the frozen noodle product after wrapping;

[0040] (2) heat-shock the wrapped frozen noodles at 45°C for 15 minutes to obtain frozen noodles after the heat-shock treatment;

[0041] (3) Precooling the frozen noodle products after heat shock treatment at 2° C. for 8 hours to obtain the frozen noodle products after precooling;

[0042] (4) Store the precooled frozen noodle products in an environment with a temperature of -4°C and a humidity of 75%.

Embodiment 3

[0044] The sub-freezing method of frozen flour products specifically comprises the following steps:

[0045] (1) Wrap the frozen noodle product with two layers of polyethylene cling film to obtain the frozen noodle product after wrapping;

[0046] (2) heat-shock the wrapped frozen noodles at 50° C. for 20 minutes to obtain frozen noodles after the heat-shock treatment;

[0047] (3) precooling the frozen noodle products after heat shock treatment at 4° C. for 10 h to obtain the frozen noodle products after precooling;

[0048] (4) Store the precooled frozen noodle products in an environment with a temperature of -6°C and a humidity of 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total number of colonies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com