Forming process for large girdles of baby diapers

A technology of baby diapers and molding process, which is applied in the fields of baby underwear, medical science, clothing, etc., and can solve the problem that the large ring waist with a length of 330mm cannot be formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

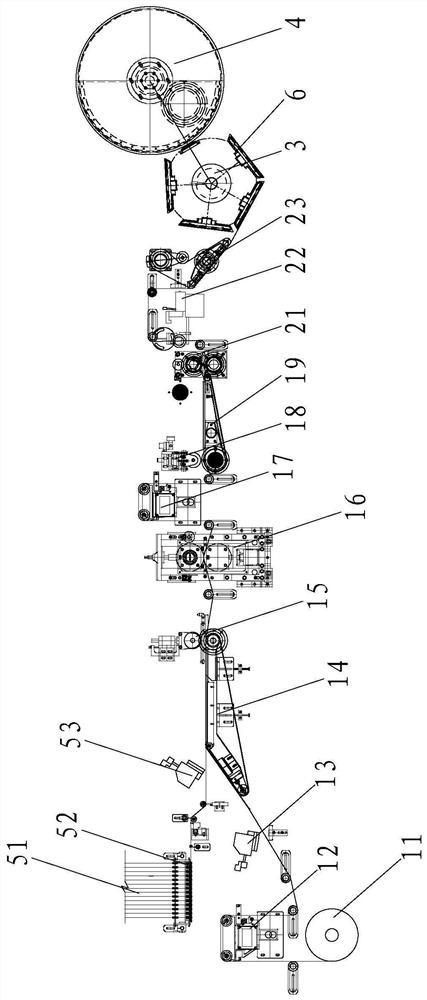

[0038] refer to Figure 1 to Figure 5 , the present embodiment provides a forming device for forming a large ring waist, the forming device includes a frame and a non-woven fabric unwinding device 11 arranged on the frame according to the assembly line, a first deviation correcting device 12, a non-woven fabric Glue spraying device 13, folding device 14, first rolling device 15, point breaking mechanism 16, second deviation correcting device 17, second rolling device 18, first adsorption conveyor belt 19, dotted line cutter mechanism 21, waist spray glue Device 22, second adsorption conveyor belt 23, indexing and transversal mechanism 3, adsorption composite wheel 4, the front end of the folding device 14 is provided with an elastic unwinding device 51 and an elastic steering wheel arranged on the frame according to the assembly line. Device 52, rub...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap