Self-heating element and preparation method therefor

A self-heating and filling technology, applied in chemical instruments and methods, heat exchange materials, other medical devices, etc., can solve the problems of long production process, no moxibustion effect, long process flow, etc., and achieve long heating time , avoid unpleasant feeling, good compliance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1.1 Prescription:

[0053] Iron powder (200 mesh) 50 parts, moxa fiber (50 mesh) 8 parts, wood fiber 4 parts, activated carbon (300 mesh) 5 parts, xanthan gum 2 parts, water 30 parts, sodium chloride 3 parts

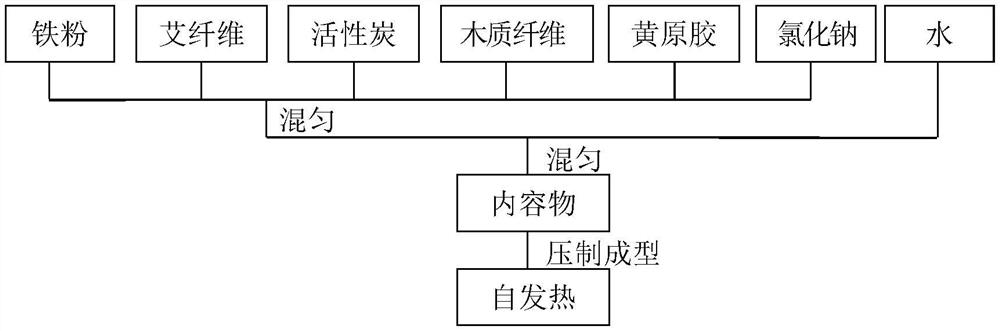

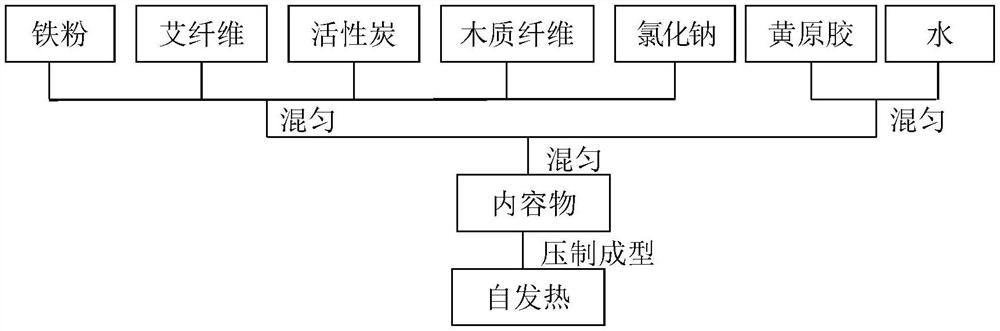

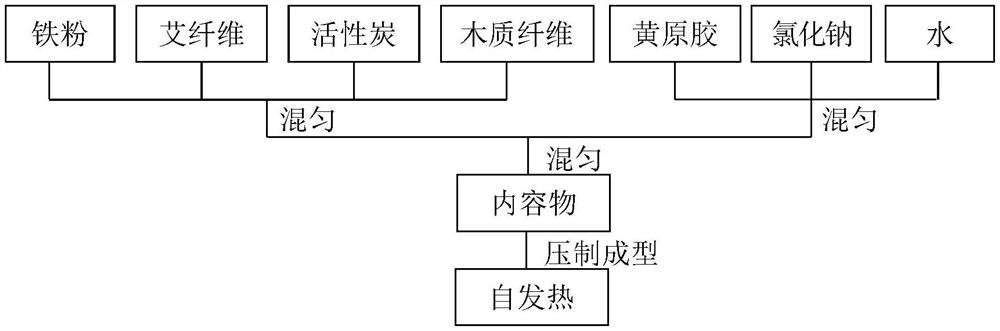

[0054] 1.2 Preparation method:

[0055] First, mix sodium chloride and xanthan gum evenly, and slowly add water to dissolve completely while stirring to obtain glue.

[0056] Next, mix the iron powder, moxa fiber, wood fiber, and activated carbon evenly, add the glue solution obtained in the above steps, mix evenly, and obtain a uniformly mixed powder, and seal it with a packaging material.

[0057] Finally, unpack the sealed package, put the powder obtained above into a tableting mold with inner packaging materials (non-woven fabric composite polyethylene film) on top and bottom, and press to form a square shape. Prepared products such as Figure 5 .

[0058] 1.3 Comparison with commercially available products

[0059] 1.3.1 Weight

[0060] as follows Image...

Embodiment 2

[0085] prescription:

[0086] 60 parts of reduced iron powder (200 mesh), 8 parts of moxa (80 mesh), 8 parts of expanded vermiculite powder (200 mesh), 6 parts of activated carbon (400 mesh), 5 parts of konjac gum, 30 parts of water, 10 parts of sodium chloride share.

[0087] Preparation:

[0088] First, mix sodium chloride and konjac gum evenly, slowly add water to dissolve completely while stirring, and obtain glue.

[0089] Next, mix iron powder, moxa, expanded vermiculite powder, and activated carbon evenly, add the glue solution obtained in the above steps, mix evenly, and obtain evenly mixed powder, and seal it with packaging materials.

[0090] Finally, unpack the sealed package, put the powder obtained above into a tableting mold with an inner packaging material (microporous polyethylene film) on top and bottom, press to form a square shape, and make indentations on the surface.

Embodiment 3

[0092] prescription:

[0093] Iron powder (320 mesh) 50 parts, moxa powder 8 parts (50 mesh), water-absorbing resin (200 mesh) 8 parts, activated carbon (600 mesh) 10 parts, guar gum 0.5 parts, water 10 parts, sodium chloride 1 part .

[0094] Preparation:

[0095] First, mix sodium chloride and guar gum evenly, slowly add water to dissolve completely while stirring, and obtain glue.

[0096] Next, mix iron powder, moxa powder, water-absorbent resin, and activated carbon evenly, add the glue solution obtained in the above steps, and mix evenly to obtain evenly mixed powder, which is sealed with packaging materials.

[0097] Finally, unpack the sealed package, put the powder obtained above into a tableting mold with inner packaging materials (paper fiber composite polyethylene film) on top and bottom, and press to form a circular shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com