Composite material arc-shaped tooth bevel gear scraping cutter

A composite material and arc-shaped tooth technology, which is applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve the problems of high cost and poor heat dissipation, and achieve easy disassembly and improved heat dissipation Effect, easy maintenance and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

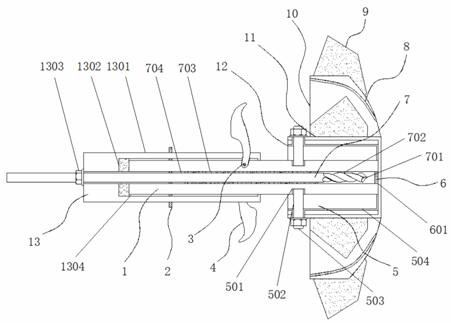

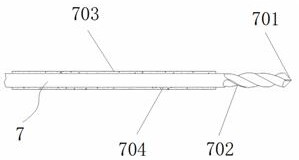

[0035]Example 1: SeeFigure 1-6A composite curved tooth cone gear scrape tool, including the hollow blade 1 and the push rod 2, the top end and the bottom end of the hollow tool holder 1 respectively provided a push rod 2, one end and bottom of the hollow tool handle 1, respectively The other end is provided with a heat dissipation blade 4, and the hollow tool handle 1 and the heat dissipation blade 4 are fixedly connected to the fixing screw 3, and the inside of the hollow tool handle 1 is provided with a polishing structure 7, and the outer portion of the hollow tool handle 1 is provided with a shockproof structure. 13, the outer portion of the hollow shank 1 is provided between the knife body 10, the other side of the blade body 10 and the hollow tool holder 1 is provided between the other sides of the blade body 5, and the hollow tool handle 1 is disposed on the other side of the hollow. Structure 6, there is a heat dissipation structure inside the blade body 10;

[0036]SeeFigure 1...

Embodiment 2

[0040]Example 2: The disassembly structure 5 is composed of a slot 501, a plug 502, mounting nut 503, and a bump 501, and the slot 501 is disposed inside the hollow tool holder 1, the plug 502 vertically through the mounting groove 12 and inserted The mounting nut 503 is fixed to the inside of the slot 501, the plug 502 and the counter body 10, and the bumps 504 are welded to the other side of the hollow tool handle 1;

[0041]The bump 504 is shown in the "ten" font, the plug 502 is embedded inside the mounting tank 12;

[0042]Specifically, such asfigure 1 withFigure 5 As shown, periodically replacing the tool body 10 or when the different specification gear is required to be scraped, the blade body 10 needs to be removed from the hollow tool handle 1, remove the mounting nut 503, and extract the plug 502 from the slot 501, will then The tool body 10 is slightly split from the hollow tool handle 1, the mounting is interpened, and the nested structure of the mounting groove 12 and the bum...

Embodiment 3

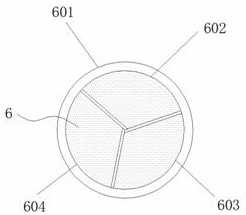

[0043]Example 3: The anticycle structure 6 consists of a washer 601, the first rubber sheet 602, the second rubber sheet 603, and the third rubber sheet 604, and the gasket 601 is fixedly attached to the other side of the hollow chamber 11, the internal ring of the washer 601. The first rubber sheet 602, the second rubber sheet 603, and the third rubber sheet 604, the first rubber sheet 602, the second rubber sheet 603, and the third rubber sheet 604 are identical;

[0044]The first rubber sheet 602, the second rubber sheet 603, and the third rubber sheet 604 are fan-shaped;

[0045]Specifically, such asfigure 1 ,figure 2 withFigure 4 As shown, the first rubber sheet 602, the second rubber sheet 603, and the third rubber sheet 604 are formed to block the hollow tool holder 1 inlet, when the drill pipe 704 projects, the drill bit 702 is grinding the blind hole of the gear. When the debris does not flush into the hollow tool holder 1, while the slider 703 continues to rub the hollow tool ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com