A kind of diode ink drying equipment

A technology for drying equipment and diodes, which is applied in lighting and heating equipment, household refrigeration equipment, semiconductor devices, etc., which can solve the problems of inconvenient processing of diodes, loss of stickiness of paper tape, and diode detachment from paper tape, etc., so as to reduce the risk of overheating and softening Probability, prevent detachment from washi tape, avoid loss of stickiness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

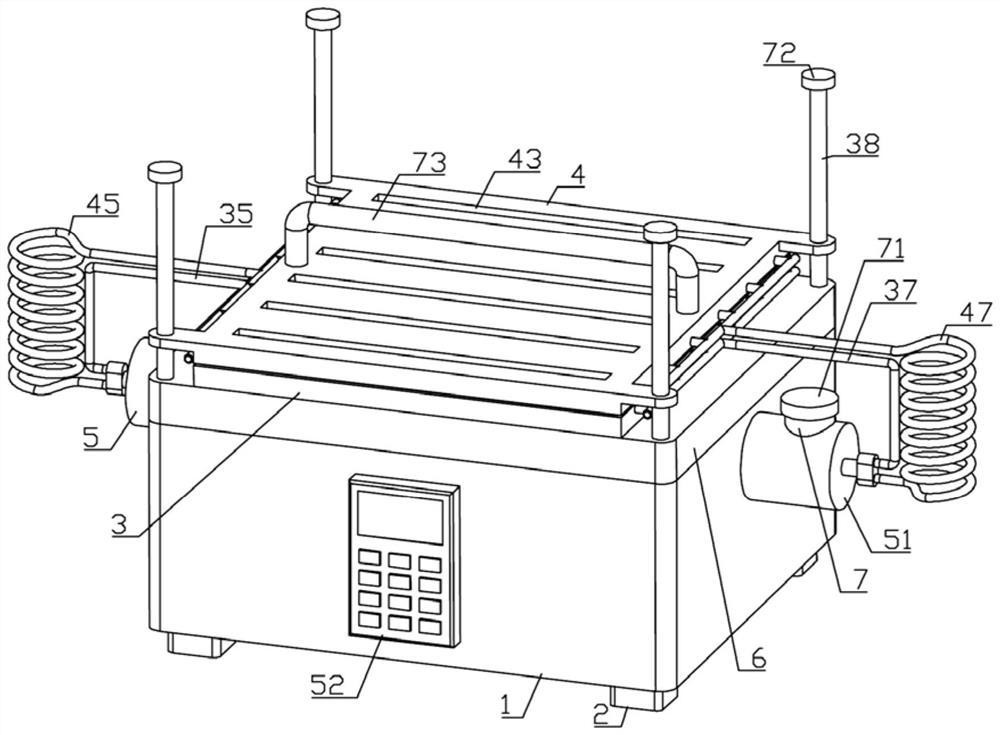

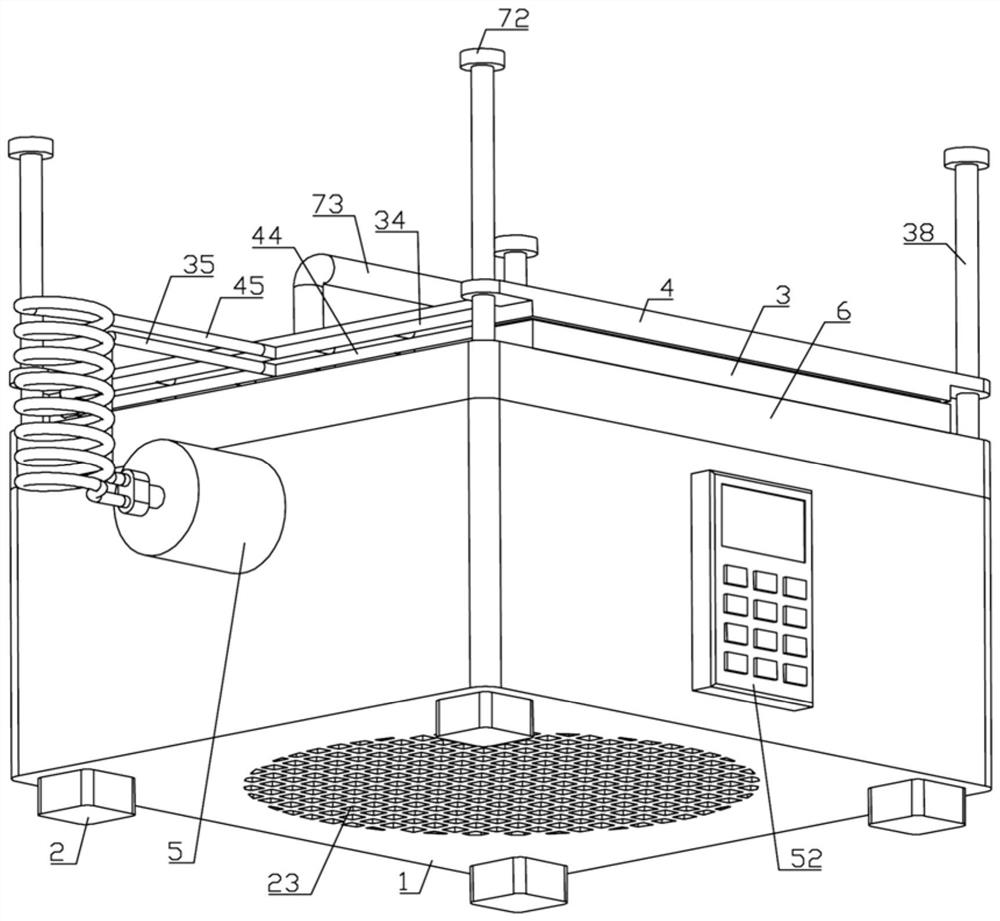

[0037] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] Such as Figure 2-9 As shown, a diode ink drying device of the present invention includes a box body 1, and the lower end of the box body 1 is provided with four support feet 2 distributed in a rectangular shape, and the inside of the box body 1 is fixedly connected with a fan 21 and a cooling fan 21 from bottom to top. The water tank 22 is filled with coolant inside the cooling water tank 22, the lower end of the box body 1 is provided with an air inlet hole 23 matching the fan 21, and the upper end of the box body 1 is fixedly connected with an electric heater 24;

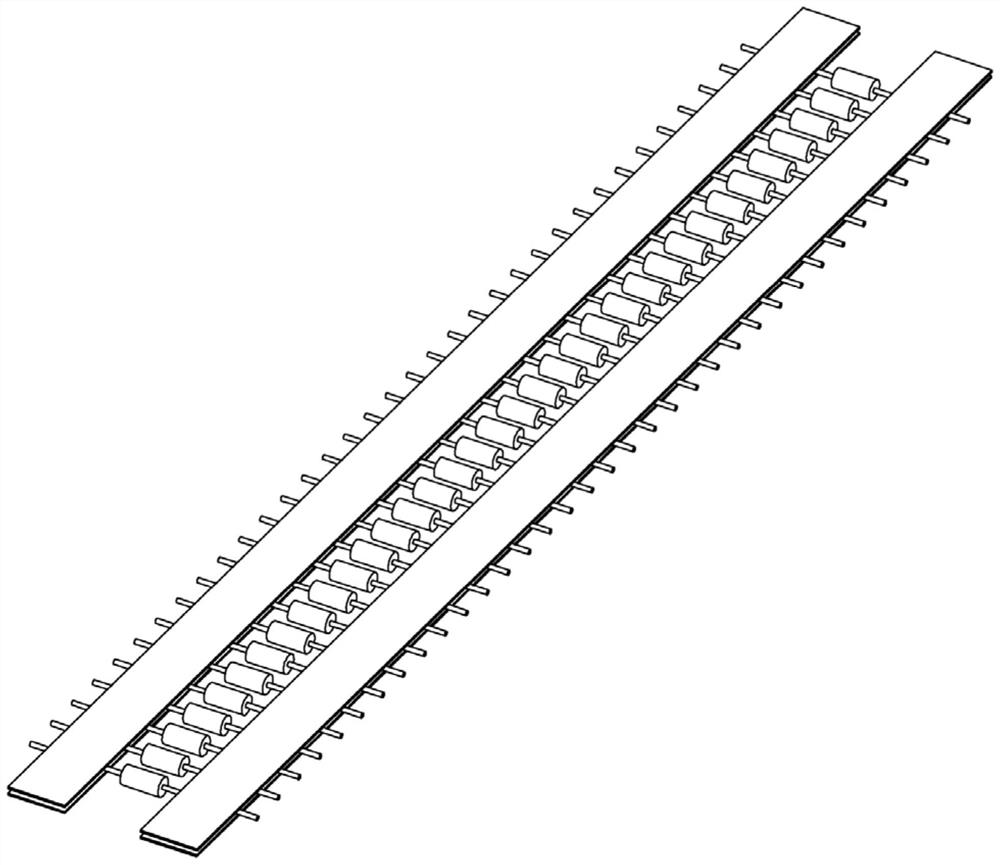

[0039] The upper end of the electric heater 24 is fixedly connected with a lower bearing plate 3, the upper end of the lower bearing plate 3 is provided with several low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com