Non-autoclaved concrete admixture, cement mixture, concrete material, concrete product and preparation method

A concrete and autoclave-free technology, which is applied in the field of concrete, can solve the problems of high dosage, high transportation cost and low activity, and achieve the effects of simplifying the preparation process, ensuring strength and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

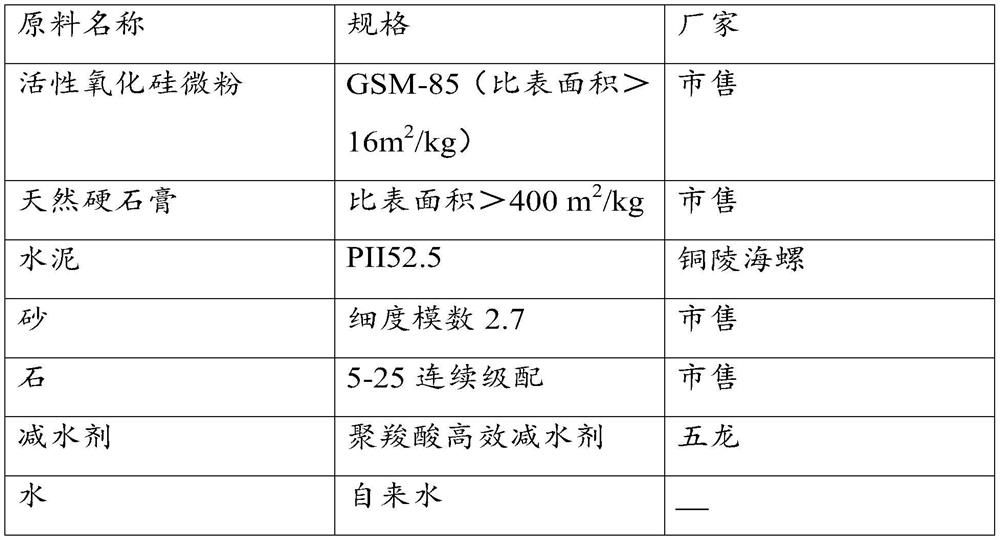

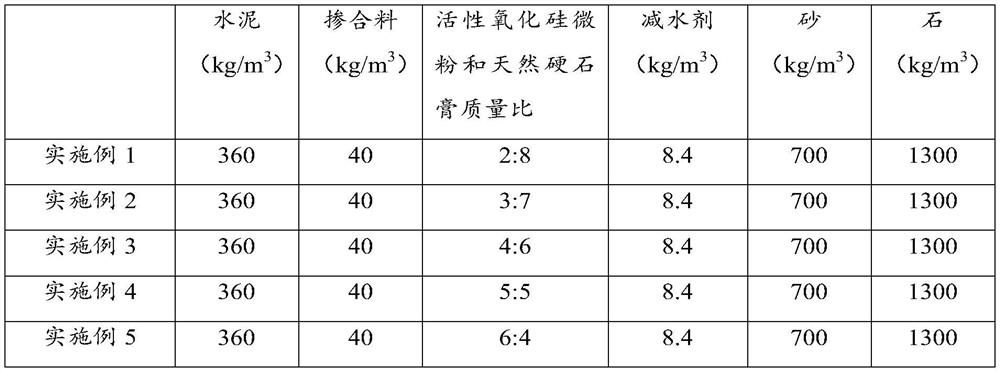

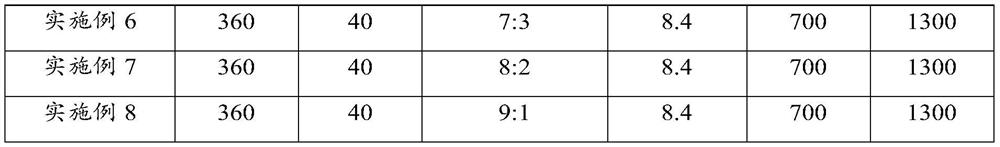

Method used

Image

Examples

preparation example Construction

[0047] According to the fifth aspect of the present invention, the present invention provides the preparation method of the above-mentioned concrete product, comprising the following steps: after the concrete material is molded, it is cured at 90-100° C. for 5-6 hours in saturated water vapor at normal pressure to obtain concrete products.

[0048] Typical but non-limiting, the curing temperature of the concrete product provided by the present invention is 90°C, 92°C, 95°C, 98°C or 100°C, and the curing time is 5h, 5.2h, 5.5h, 5.8h or 6h .

[0049] The preparation method of the concrete product provided by the present invention can reach the traditional secondary curing process (atmospheric pressure after the concrete is formed) Baohe steam curing for 6 hours, and then the strength of concrete products after continuous curing in 1.0Mpa pressure saturated steam for 8 hours in a high-pressure curing kettle, the process is simpler, and it can effectively save manpower and materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com