Production method and production system for preparing organic fertilizer by mixing livestock manure with human manure

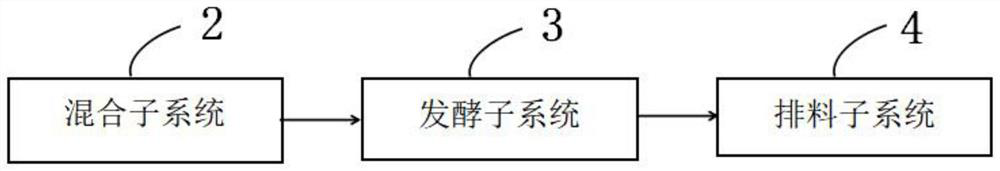

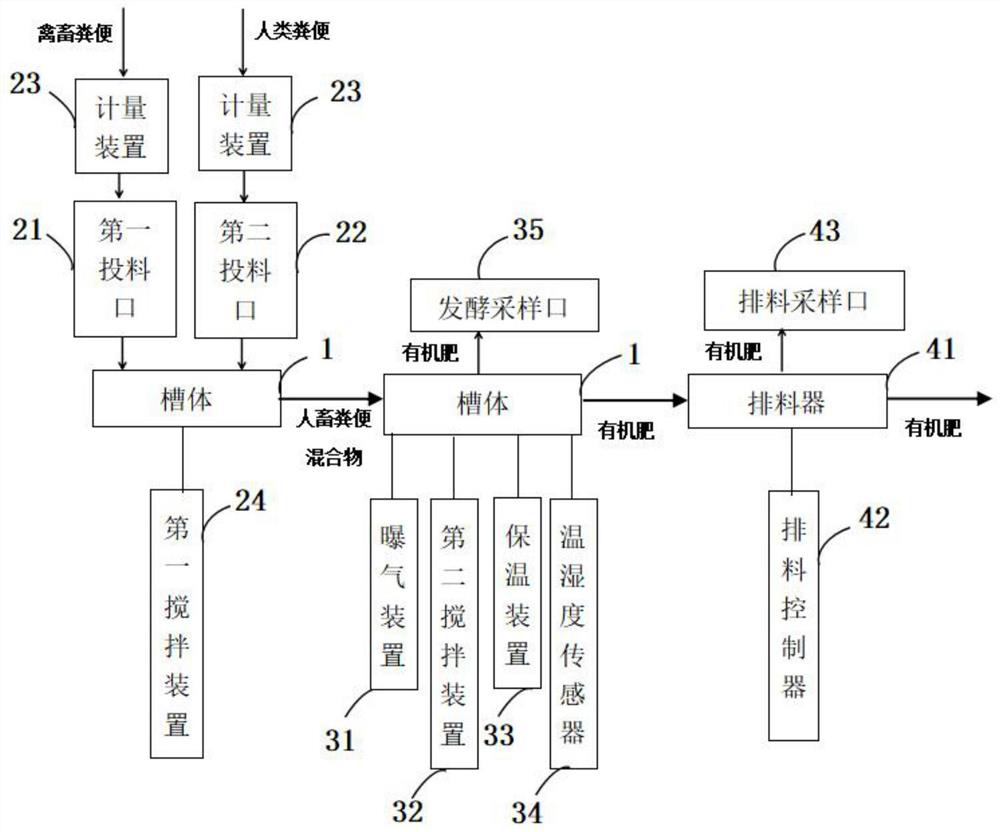

A technology of livestock manure and production method, which is applied in the directions of organic fertilizers, fertilization devices, excretion fertilizers, etc., can solve the problems of high environmental requirements, poor environmental adaptability, long processing cycles, etc., and achieves reduction of costs, shortening of processes, and improvement of fermentation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] When the carbon-nitrogen ratio of the mixture of human and livestock manure is 15:1 and the water content is 45%, the fermentation period of the mixture of human and livestock manure into organic fertilizer is 7 days, the fermentation temperature is 50-80°C, and the high temperature period is 70-80°C. The duration of the fermentation period accounts for 2 / 3 of the fermentation period.

[0070] The moisture content of the organic fertilizer is 31.50%. The organic matter content of the organic fertilizer is 54.30% based on the drying basis, the total nitrogen content based on the drying basis is 7.62%, the total potassium content based on the drying basis is 5.37%, and the total phosphorus content based on the drying basis is 4.53%, the content of coliform bacteria in the organic fertilizer is 10 / g, the pH value is 7.5, and the germination rate of the seeds fertilized by the organic fertilizer is 110.86%.

Embodiment 2

[0072] When the carbon-nitrogen ratio of the mixture of human and livestock manure is 10:1, and the water content is 45%, the fermentation period of the mixture of human and livestock manure into organic fertilizer is 15 days, the fermentation temperature is 50-80°C, and the high temperature period is 70-80°C. The duration of the high temperature period accounts for 2 / 3 of the fermentation period.

[0073] The moisture content of the organic fertilizer is 34.20%. The organic matter content of the organic fertilizer based on the drying basis is 50.20%, the total nitrogen content based on the drying basis is 7.04%, the total potassium content based on the drying basis is 4.19%, and the total phosphorus content based on the drying basis is 4.96%, the content of coliform bacteria in the organic fertilizer is 180 / g, the pH value is 7.9, and the germination rate of the seeds fertilized by the organic fertilizer is 90.21%.

Embodiment 3

[0075] When the carbon-nitrogen ratio of human and livestock manure mixture is 20:1, and the water content is 50%, the fermentation period of human and animal manure mixture into organic fertilizer is 16 days, the fermentation temperature is 50-80°C, and the high temperature period is 70-80°C. The duration of the high temperature period accounts for 2 / 3 of the fermentation period.

[0076] The moisture content of the organic fertilizer is 34.60%. The organic matter content of the organic fertilizer is 46.40% based on the drying basis, the total nitrogen content based on the drying basis is 6.51%, the total potassium content based on the drying basis is 3.87%, and the total phosphorus content based on the drying basis is 4.59%, the content of coliform bacteria in the organic fertilizer is 160 / g, the pH value is 6, and the germination rate of the seeds fertilized by the organic fertilizer is 98.47%.

[0077] Example 3

[0078] When the carbon-nitrogen ratio of the mixture of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com