Low-temperature-resistant elastomer rubber composition and application thereof

A technology of rubber composition and low temperature resistance, which is applied in the field of rubber materials and can solve problems such as large swelling, unsatisfactory air tightness, and poor air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0031] An embodiment of the low temperature resistant elastomeric rubber composition of the present invention.

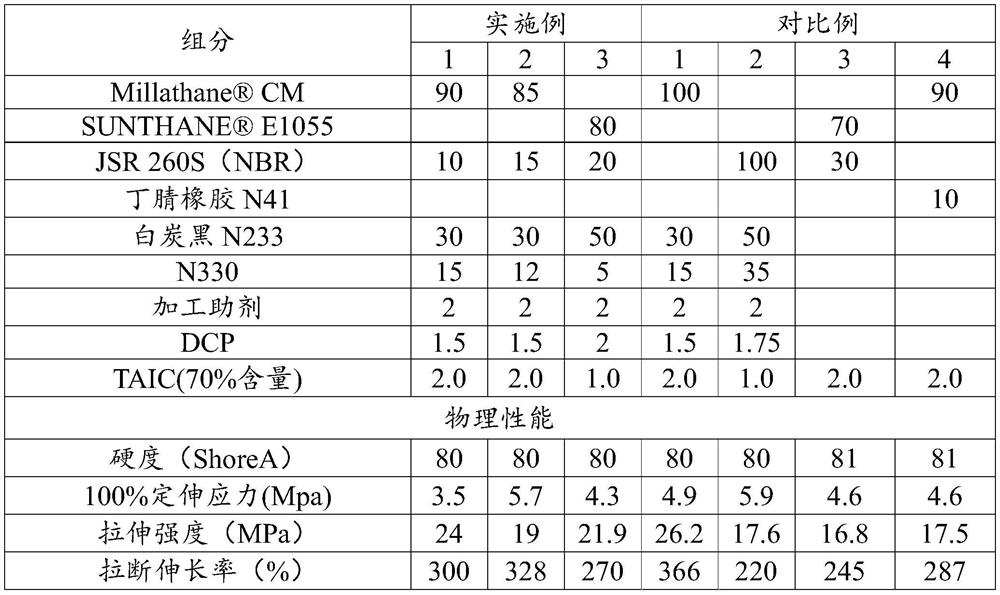

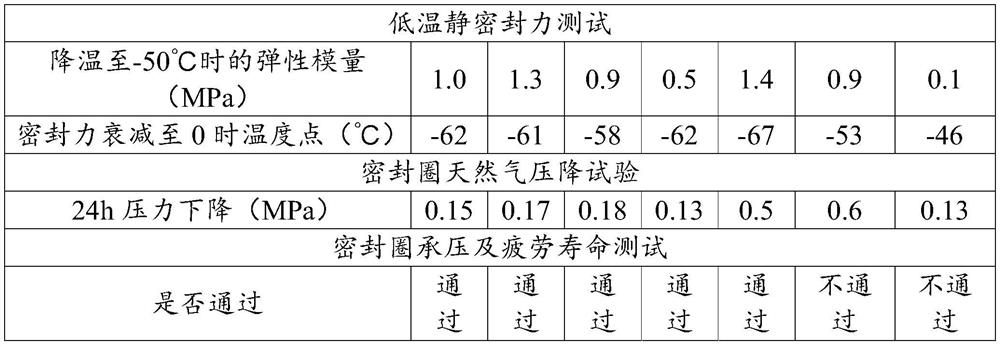

[0032] The components and parts by weight of the low-temperature resistant elastomer rubber composition in the examples are shown in Table 1. In order to ensure the follow-up performance test, the formulations of each example are uniformly designed so that the product meets the GB / T531 standard with a hardness of 80 Shore a.

[0033] The mixing type polyurethane rubber used in the described embodiment is produced by U.S. TSE Company respectively CM and Guangzhou Shunli Polyurethane Co., Ltd. E1055; the nitrile rubber used is JSR 260S; the reinforcing filler used is N233 type silica and N330 type carbon black; the processing aid used is hard amide; the peroxide used is DCP crosslinking agent; The agent is TAIC (70%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com