A collaborative manufacturing system and control method based on industrial Internet

An industrial Internet and collaborative manufacturing technology, applied in manufacturing computing systems, biological neural network models, data processing applications, etc., can solve problems such as the inability to realize independent coordination of processes and spare parts, and affect the delivery schedule of final products, achieving fast computing speed , high accuracy, and the effect of reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to better illustrate the present invention, a detailed description will be given below with reference to the accompanying drawings and specific embodiments.

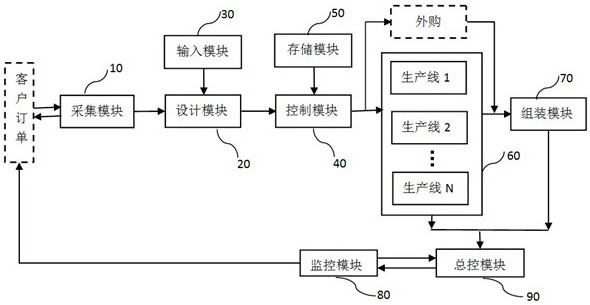

[0048] refer to figure 1 , the industrial Internet-based collaborative manufacturing platform and system according to the present invention is composed of the following parts:

[0049] Information collection module 10 , manual input module 20 , design module 30 , storage module 40 , control module 50 , production module 60 , assembly module 70 , monitoring module 80 , and general control module 90 .

[0050] The information collection module 10 is used to collect and sort out the customer's demand orders, and can also send the customer's order status to the client, so that the customer can know the order situation in time. The acquisition module 10 is connected with the design module 20 through a data bus.

[0051] The design module 20 is used to receive the customer order details sent by the collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com