Edge passivation method of HJT battery

A battery and edge technology, which is applied in the field of HJT batteries, can solve the problems of amorphous silicon film structure damage, severe cutting surface recombination, HJT battery efficiency loss, etc., and achieve good passivation effect, high production efficiency, and high conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

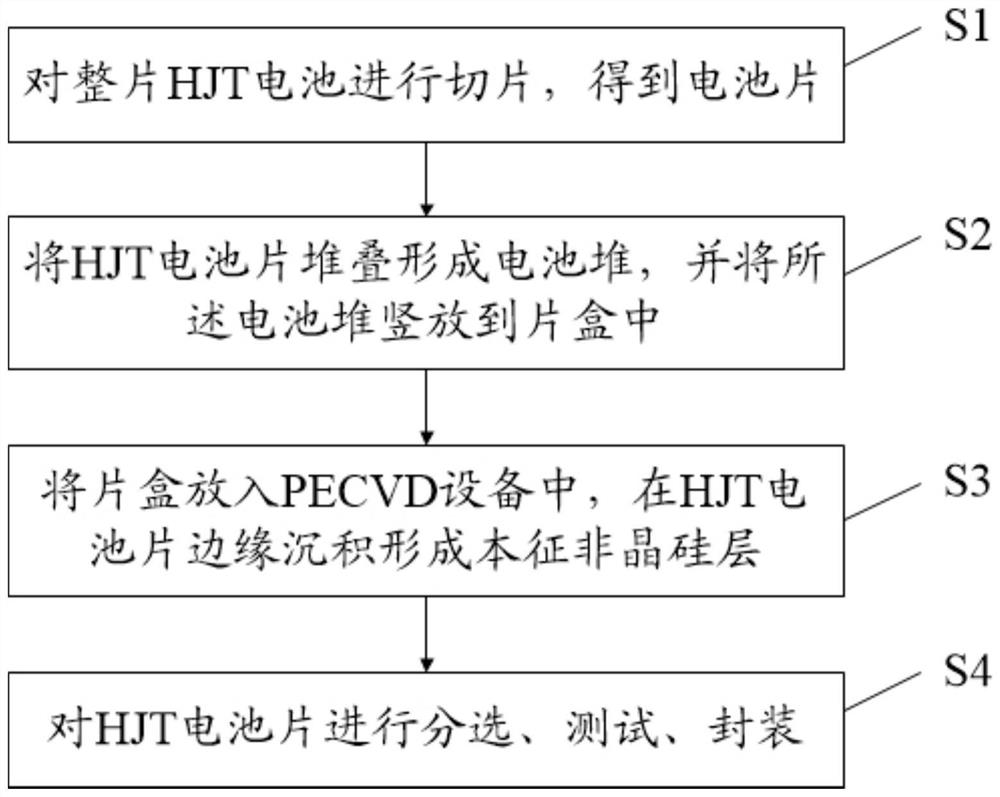

[0055] (1) Slicing the whole HJT battery to obtain HJT battery slices;

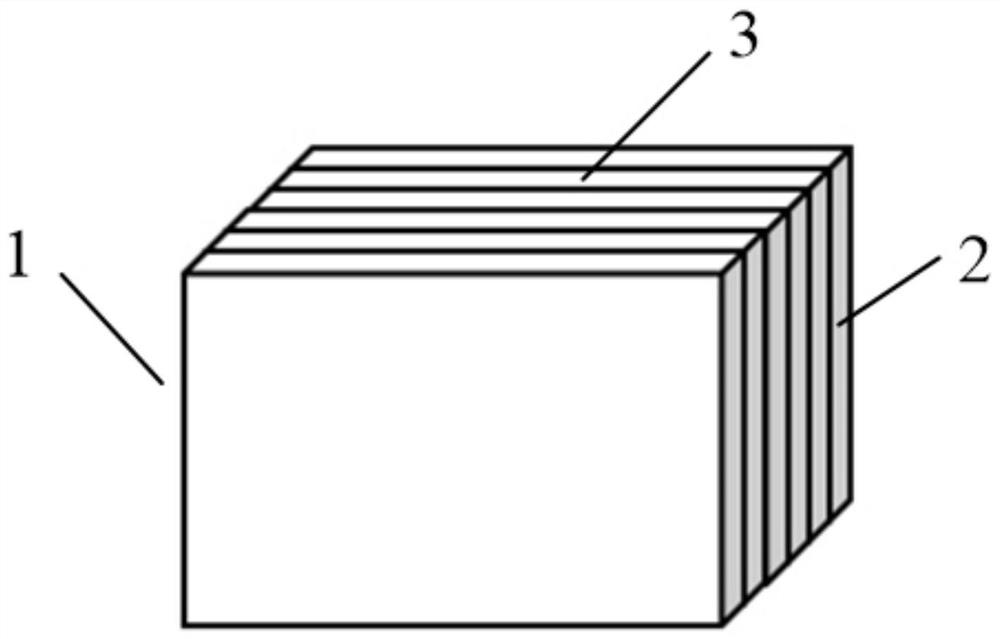

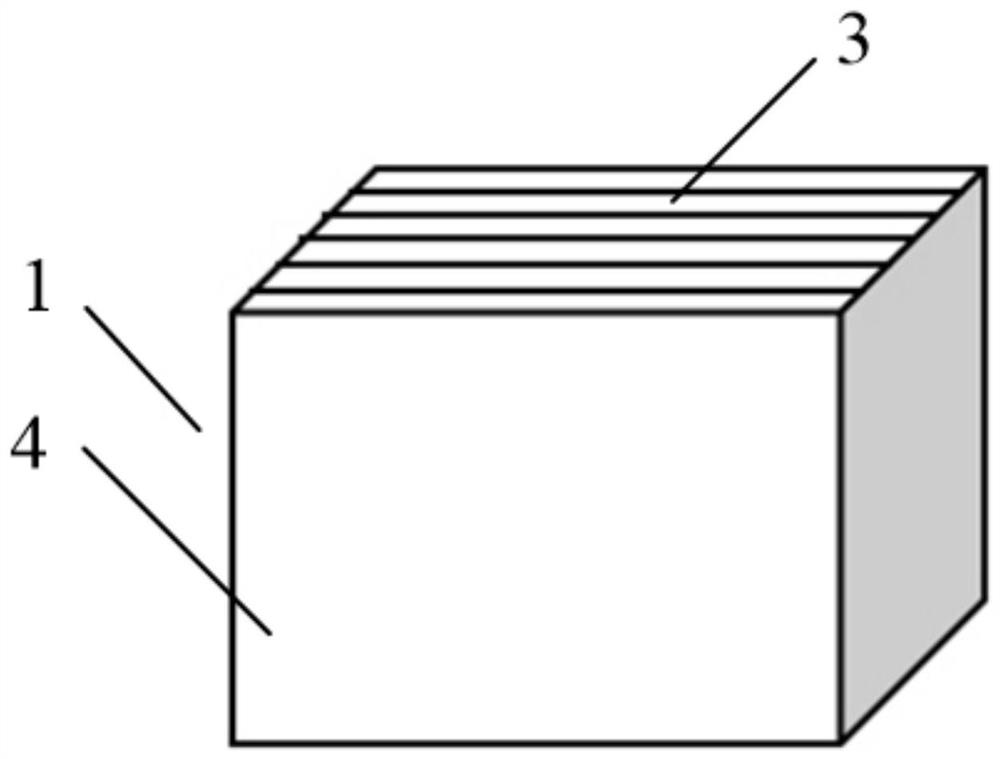

[0056] (2) Stack the HJT cells to form a cell stack, and place the cell stack vertically in the sheet box;

[0057] (3) Put the film cassette into the PECVD equipment, under the conditions of working power of 2000W and chamber pressure of 3Torr, feed SiH 4 and H 2 , depositing an intrinsic amorphous silicon layer on the edge of the HJT cell, the deposition temperature is 230°C, and the deposition time is 200s; the thickness of the intrinsic amorphous silicon layer is obtained to be 50nm;

[0058] (4) Sorting, testing and packaging the HJT cells.

Embodiment 2

[0060] (1) Slicing the whole HJT battery to obtain HJT battery slices;

[0061] (2) Stack the HJT cells to form a cell stack, and place the cell stack vertically in the sheet box;

[0062] (3) Put the cassette into the PECVD equipment, under the condition of working power of 800W and chamber pressure of 1Torr, feed SiH 4 and H 2 , depositing an intrinsic amorphous silicon layer on the edge of the HJT cell, the deposition temperature is 180°C, and the deposition time is 20s; the thickness of the intrinsic amorphous silicon layer is obtained to be 10nm;

[0063] (4) Sorting, testing and packaging the HJT cells.

Embodiment 3

[0065] (1) Slicing the whole HJT battery to obtain HJT battery slices;

[0066] (2) Stack the HJT cells to form a cell stack, and place the cell stack vertically in the sheet box;

[0067] (3) Put the cassette into the PECVD equipment, under the conditions of working power of 1000W and chamber pressure of 2Torr, feed SiH 4 and H 2 , depositing an intrinsic amorphous silicon layer on the edge of the HJT cell, the deposition temperature is 200°C, and the deposition time is 80s; the thickness of the intrinsic amorphous silicon layer is obtained to be 30nm;

[0068] (4) Sorting, testing and packaging the HJT cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deposition thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com