Grid-electricity hybrid composite glass sintered watertight connector and composite glass forming process

A technology of watertight connectors and composite glass, which is applied in the direction of connection, two-part connection devices, and parts of connection devices. The effects of modernization, data security assurance, and reliable longitudinal sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

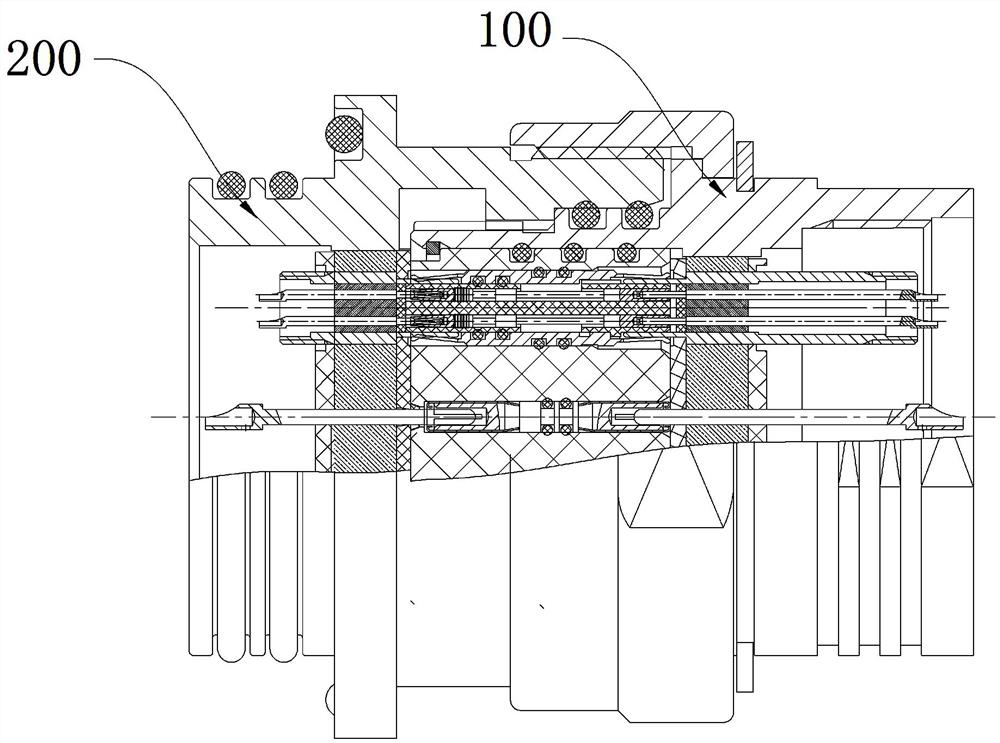

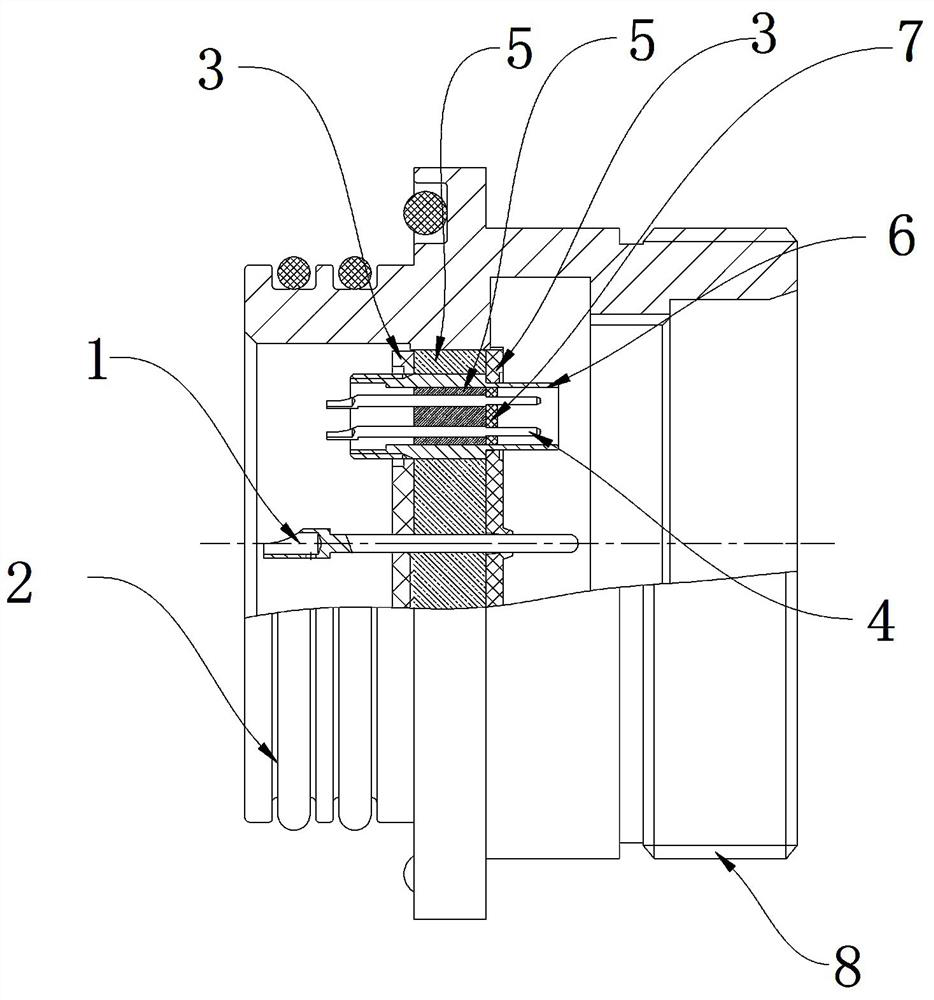

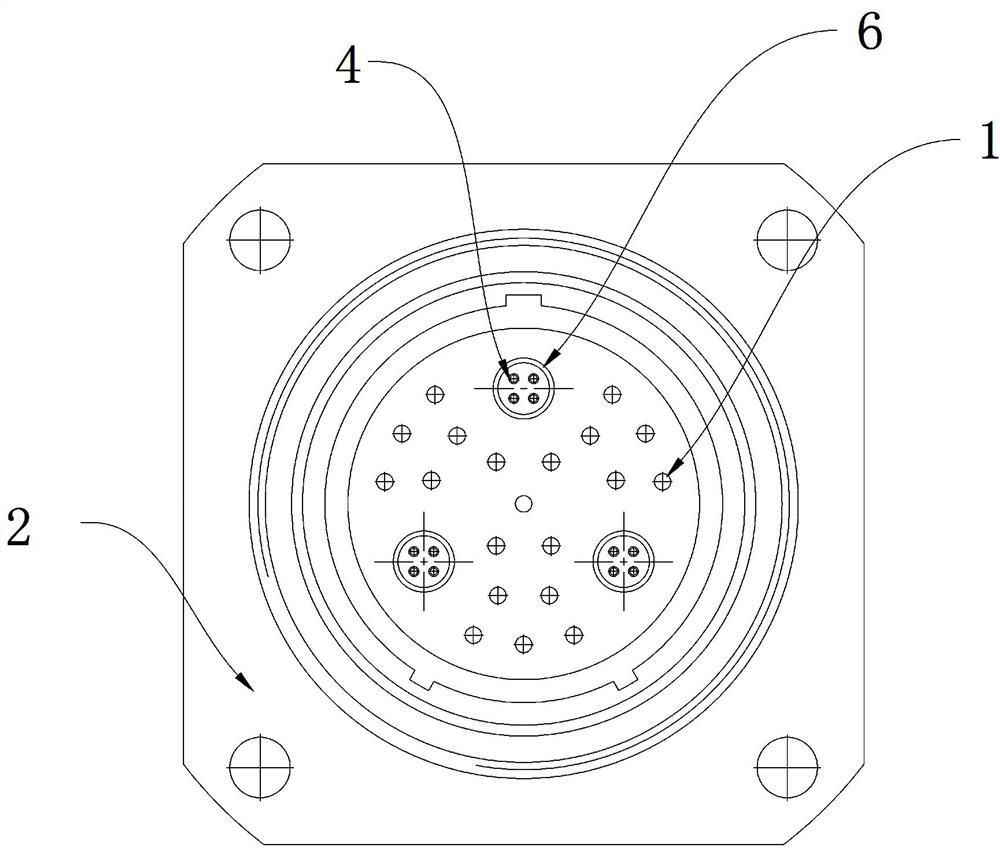

[0037] Such as figure 1 As shown, the network power hybrid composite glass sintered watertight connector includes a plug 100 and a socket 200; as figure 2 with image 3As shown, in this embodiment, the socket 200 includes a shell a2, several coaxial shells a6 and several pins a1, and several four-coaxial shells a6 and several pins a1 are installed in the shell a2 through glass insulators a5, and several four-coaxial shells a6 and several pins a1 are installed in the shell a2 The coaxial housing a6 and several contact pins a1 are arranged at intervals, and a number of contact pins b4 are installed in the coaxial housing a6 through the glass insulator a5. The housing a2, the coaxial housing a6 and the contact pins a1 are all metal parts. Among them, the material of the housing a2 It is a kind of stainless steel, titanium alloy and copper alloy. Preferably, the shell a2 is made of stainless steel, the pin a1 is a low-frequency signal pin, and the material of the pin a1, the coa...

Embodiment 2

[0050] Composite glass molding process for network power hybrid composite glass sintered watertight connector, which includes the following steps:

[0051] S1: Sintering mold design and pre-treatment: before use, clean the sintering mold with clean water to remove dust, avoid entering the glass interior and affect the insulation performance, in order to avoid the adhesion caused by the catalysis of the metal on the graphite mold at high temperature, and then in the muffle furnace Heating, the heating time is preferably 30 minutes, and the heating temperature is 750°C;

[0052] S2: Metal and contact parts treatment before sintering: the outer shell needs to be activated, the inner shell needs to be oxidized, and the inner and outer contacts need to be oxidized; preferably, the inner shell needs to be oxidized for 15 minutes, and the inner and outer shells need to be oxidized. The contact parts need to be oxidized for 20 minutes.

[0053] S3: Assembling, assembling the treated ...

Embodiment 3

[0059] Composite glass molding process for network power hybrid composite glass sintered watertight connector, which includes the following steps:

[0060] S1: Sintering mold design and pre-treatment: before use, clean the sintering mold with clean water to remove dust, avoid entering the glass interior and affect the insulation performance, in order to avoid the adhesion caused by the catalysis of the metal on the graphite mold at high temperature, and then in the muffle furnace Heating, the heating time is preferably 30 minutes, and the heating temperature is 850°C;

[0061] S2: Metal and contact parts treatment before sintering: the outer shell needs to be activated, the inner shell needs to be oxidized, and the inner and outer contacts need to be oxidized; preferably, the inner shell needs to be oxidized for 15 minutes, and the inner and outer shells need to be oxidized. The contact parts need to be oxidized for 20 minutes.

[0062] S3: Assembling, assembling the treated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com