Refractory clay ingate piece

A technology of refractory clay and ingates, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problem of large local strength differences of sand ingates, affecting the internal quality of high manganese steel frogs, increasing the Workers' labor intensity and other issues, to achieve the effect of improving internal quality, increasing intensity, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

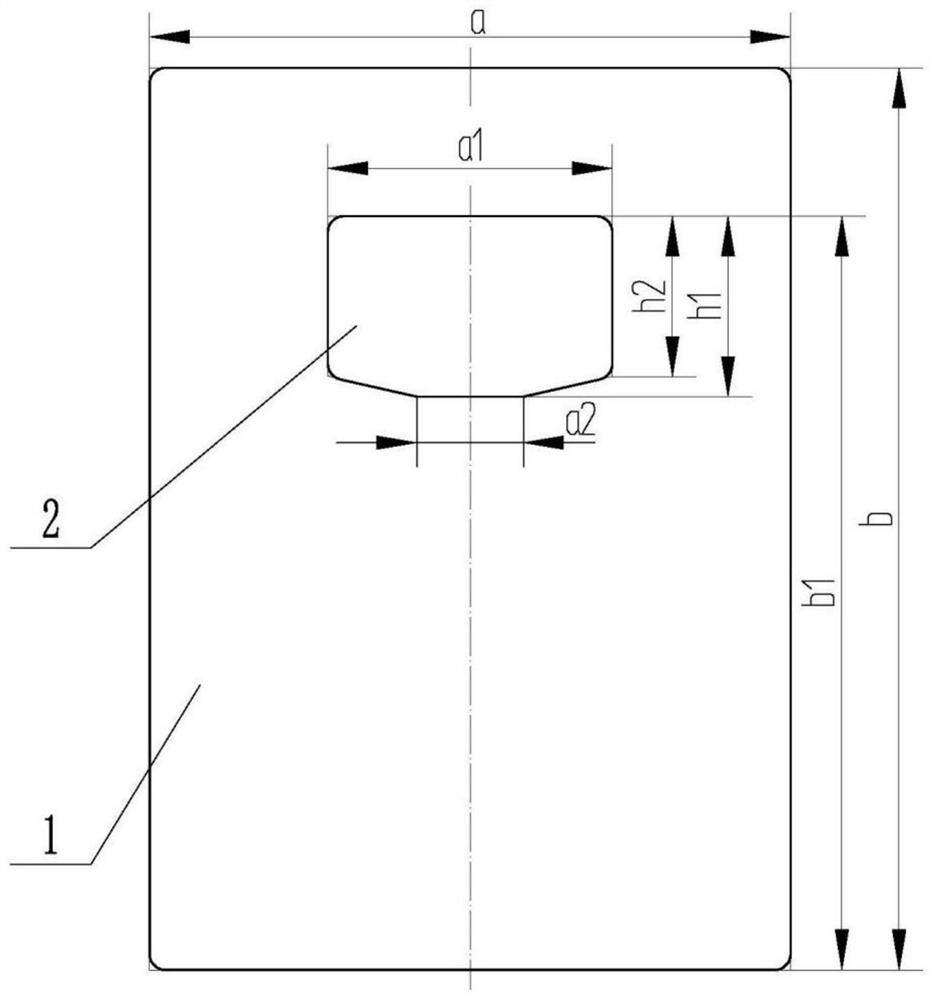

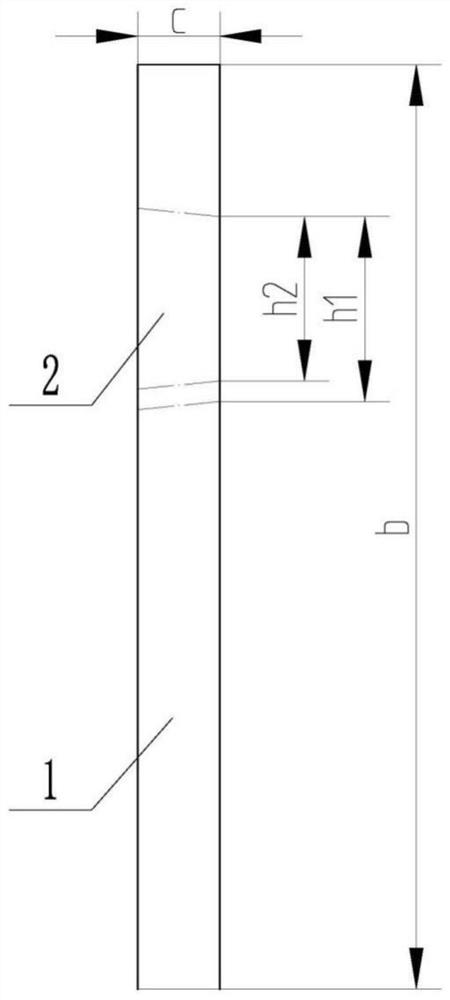

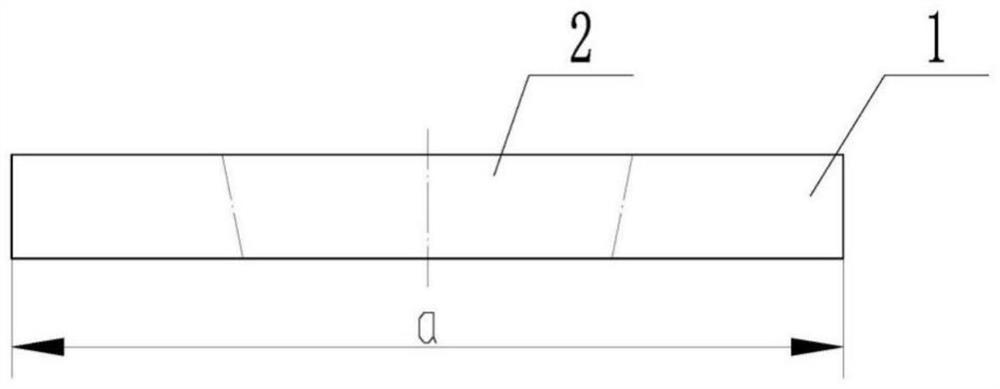

[0017] The embodiment of the present invention provides a refractory clay ingate, specifically as Figure 1~3 As shown, the sprue piece includes a sprue piece body 1 and an ingate 2 passing through the left and right surfaces of the sprue piece body 1. The sprue piece is made of refractory clay, and the sprue piece body 1. The shape is rectangular; the ingate 2 has a draft angle of 1:10, and the side with the smaller opening is in contact with the mold cavity, and the side with the larger opening is in contact with the runner. Connecting the runner to the mold cavity facilitates the falling of the casting and the gating system when the subsequent gating system falls naturally; in addition, the middle of the bottom of the inrunner 2 is a plane structure, and the shape of the two ends of the plane st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com