Recycled aggregate screening pretreatment device and using method thereof

A technology of pretreatment device and recycled aggregate, applied in the field of building materials, can solve the problems of poor durability, high crushing index, large slump loss, etc., and achieve the effect of improving strength, improving neatness, and improving fusion degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

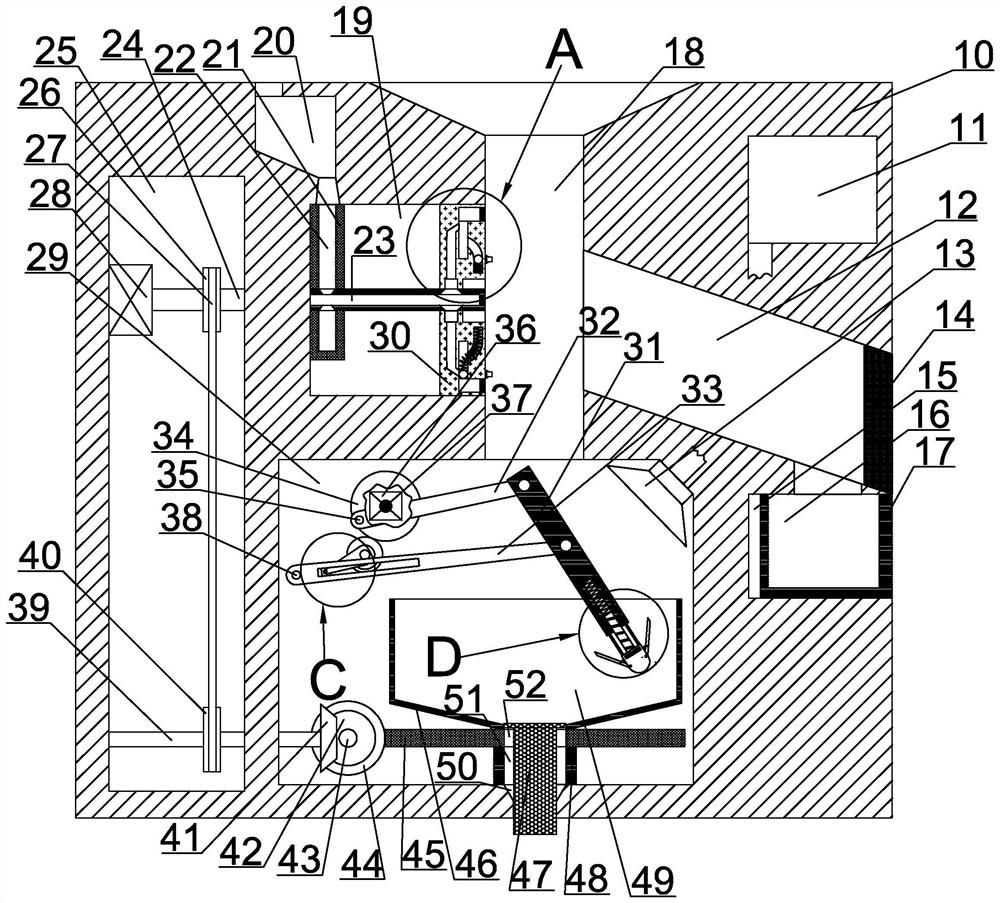

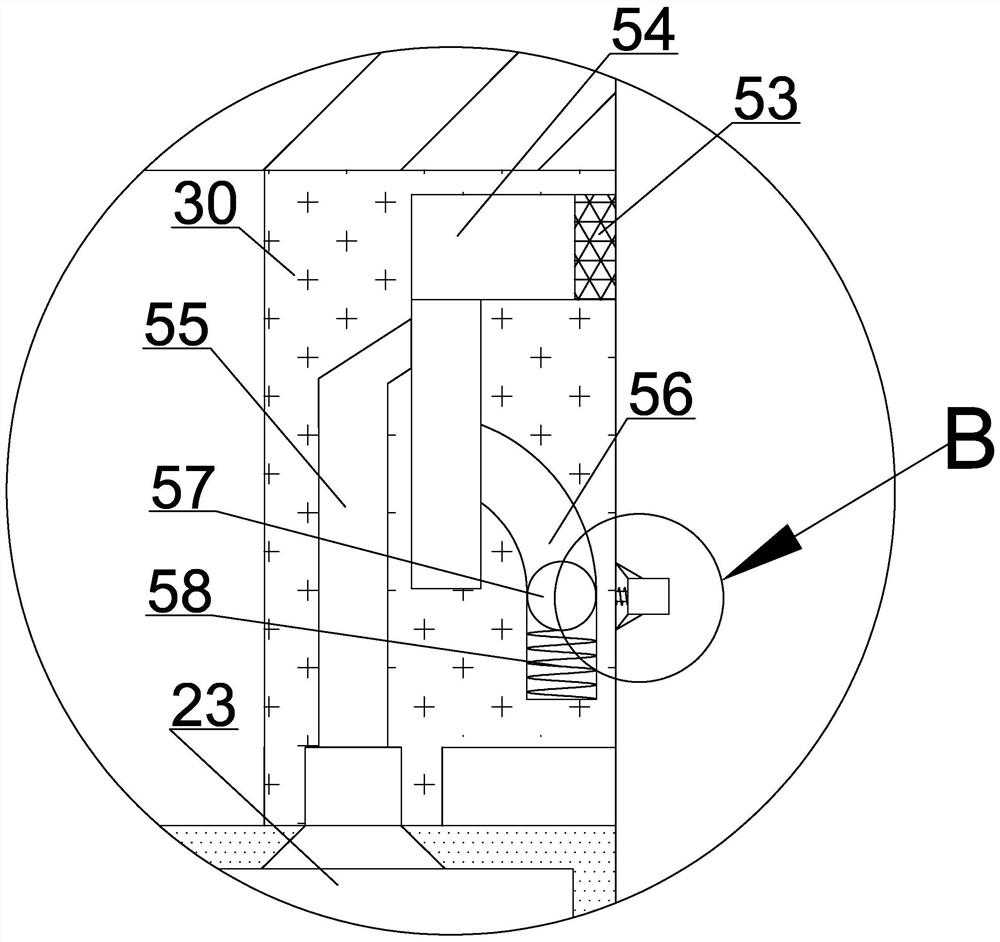

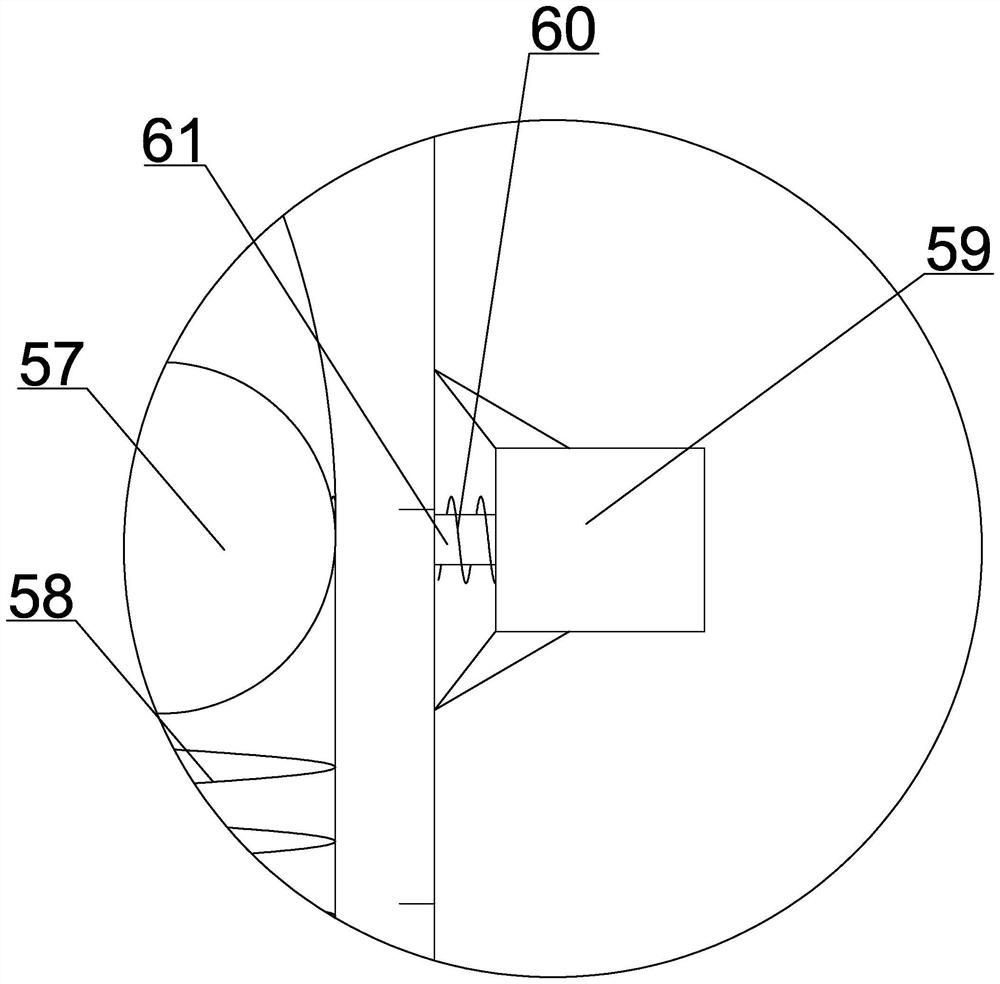

[0026] Such as figure 1 As shown, a regenerated aggregate screening pretreatment device and its use method include a machine body 10, which is characterized in that: the machine body 10 is provided with a power space 25, and the power space 25 is provided with a device for providing the device with Power mechanism, the right side of the power space 25 is provided with an air sieve space 19, and the air sieve space 19 is provided with an air sieve mechanism, and the air sieve mechanism is used to remove small particles that do not meet the particle size requirements in the recycled aggregate The granular aggregate reduces the dust concentration in the recycled aggregate at the same time. A stirring space 29 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com