Multi-wall sandwich structure carbon fiber composite material and preparation method thereof

A technology of sandwich structure and composite material, applied in the field of carbon fiber composite material forming process, can solve the problems of skin and sandwich structure failure and debonding, stress concentration, poor overall mechanical properties, etc., to improve quality stability, uniform distribution Load distribution, the effect of improving the integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment 1 provides a multi-wall sandwich structure carbon fiber composite material and a preparation method thereof, comprising the following steps:

[0036] Step (1) Processing and cutting of main body foam core, foam sheet, carbon fiber fabric and carbon fiber prepreg:

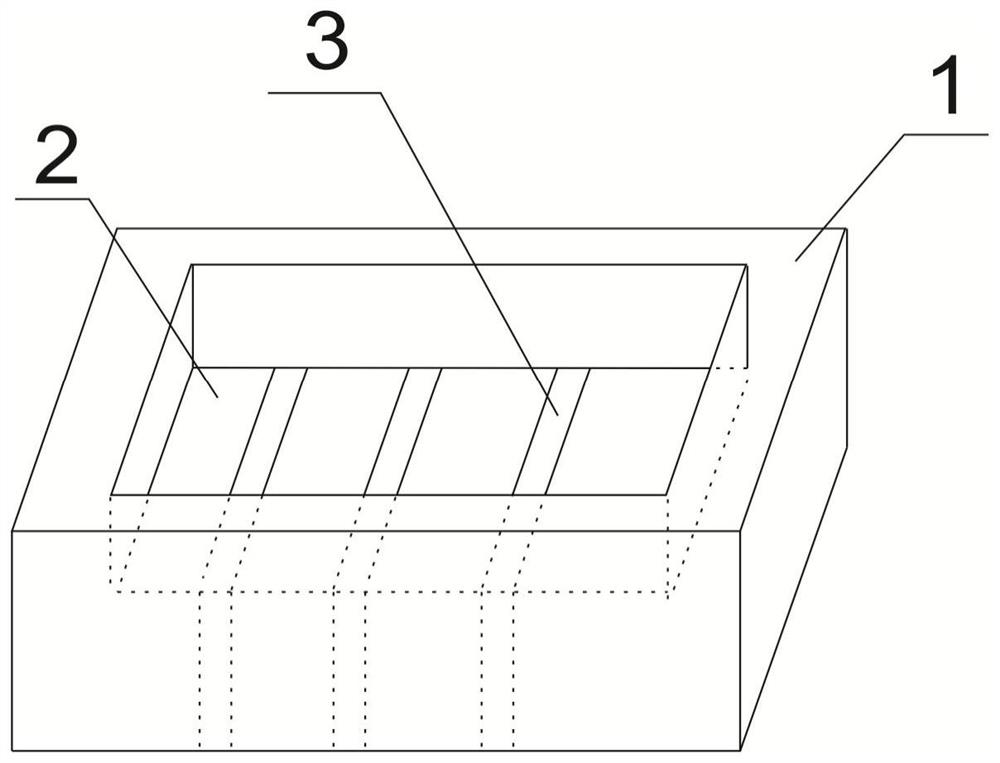

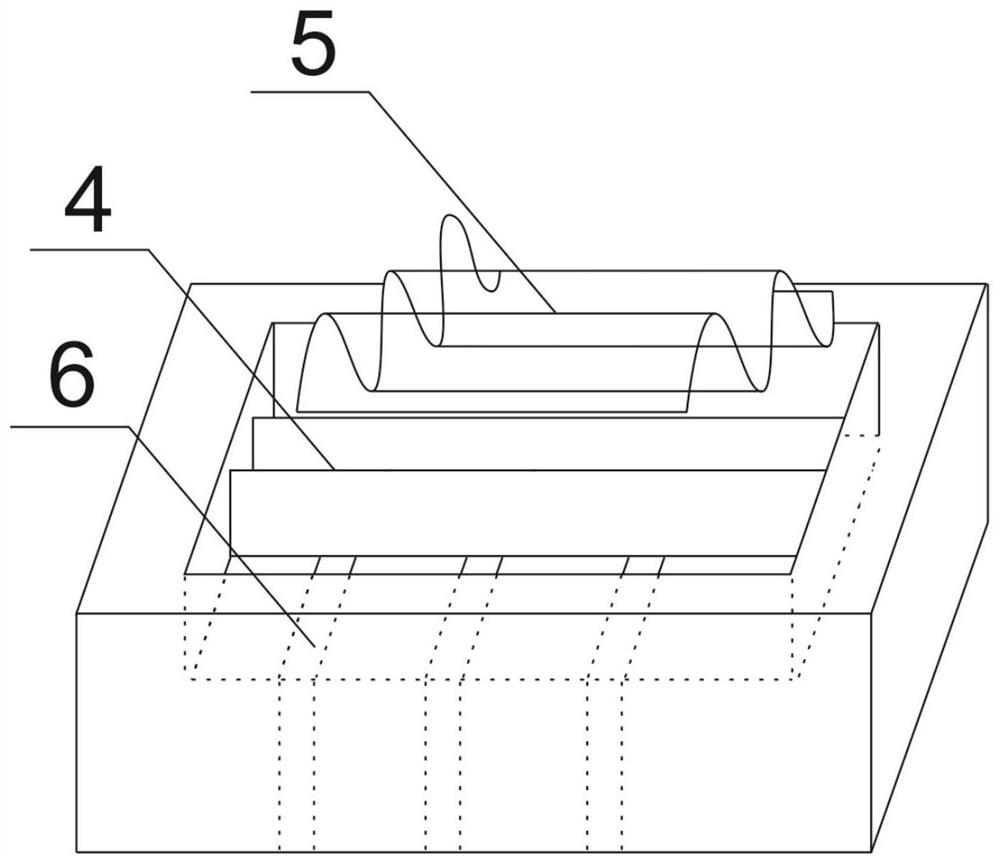

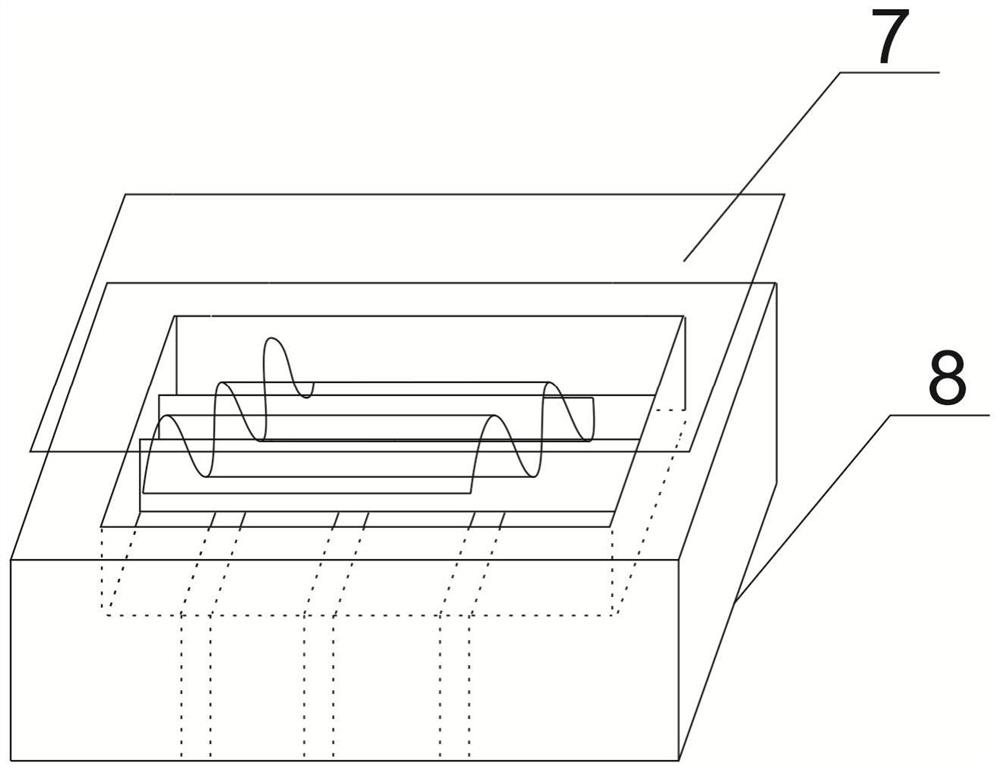

[0037] Take the center line as the base point of the main body foam core and use a milling cutter to process a rectangular groove above it with a distance of 8cm from the center line, 1.5cm from the upper edge, 3cm from the lower edge, and 1.5cm deep. A rectangular slit with a length of 3 cm and a width of 0.12 cm, the first slit is 4 cm from the left side of the rectangular slot, the second slit is 4 cm from the first, the third slit is 4 cm from the second, and the foam sheet is processed with a band saw It is a sheet with a length of 16cm, a width of 1.5cm and a height of 0.25mm. The number of foam sheets is 6. The carbon fiber fabric is cut into a carbon fiber fabric with a length of 4cm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com