Laminated glass for vehicle window and preparation method thereof

A technology for laminated glass and car windows, applied in windshields, chemical instruments and methods, glass/slag layered products, etc. Degumming and other problems, to achieve good penetration resistance, good impact resistance, and the effect of promoting energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

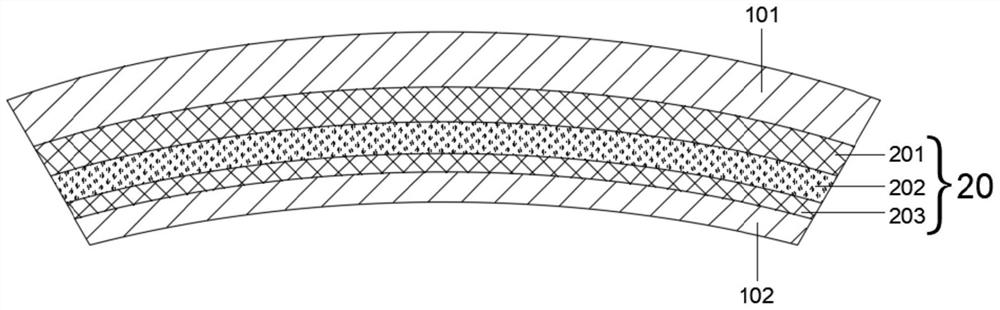

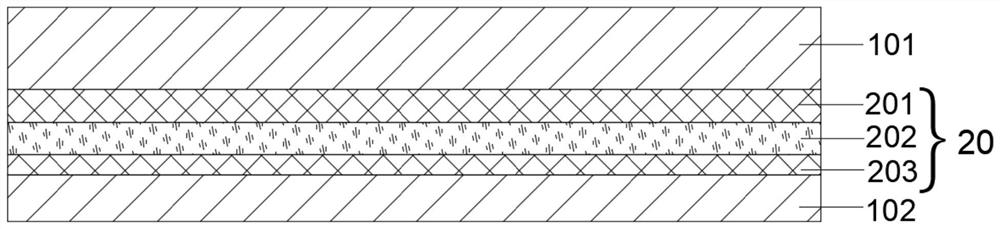

preparation example Construction

[0068] The present application also provides a method for preparing the above-mentioned laminated glass, comprising the following steps:

[0069]Step 100: providing the first glass layer, the second glass layer, the second rigid layer and the first rigid layer, pre-cutting and pre-bending the first rigid layer and the second rigid layer according to the size of the glass and the curved surface;

[0070] Step 200: Laminate the second glass layer, the second rigid layer, the flexible layer, the first rigid layer, and the first glass layer in sequence, and remove the redundant second rigid layer, flexible layer, and first rigid layer to make the edges of the glass flush , to get the laminated body;

[0071] Step 300: Pre-exhaust the laminated body to remove the air between the layers, then place the laminated body in an autoclave for reaction, and obtain a laminated glass after cooling.

[0072] In the embodiment of the present application, in step 100, the first glass layer and...

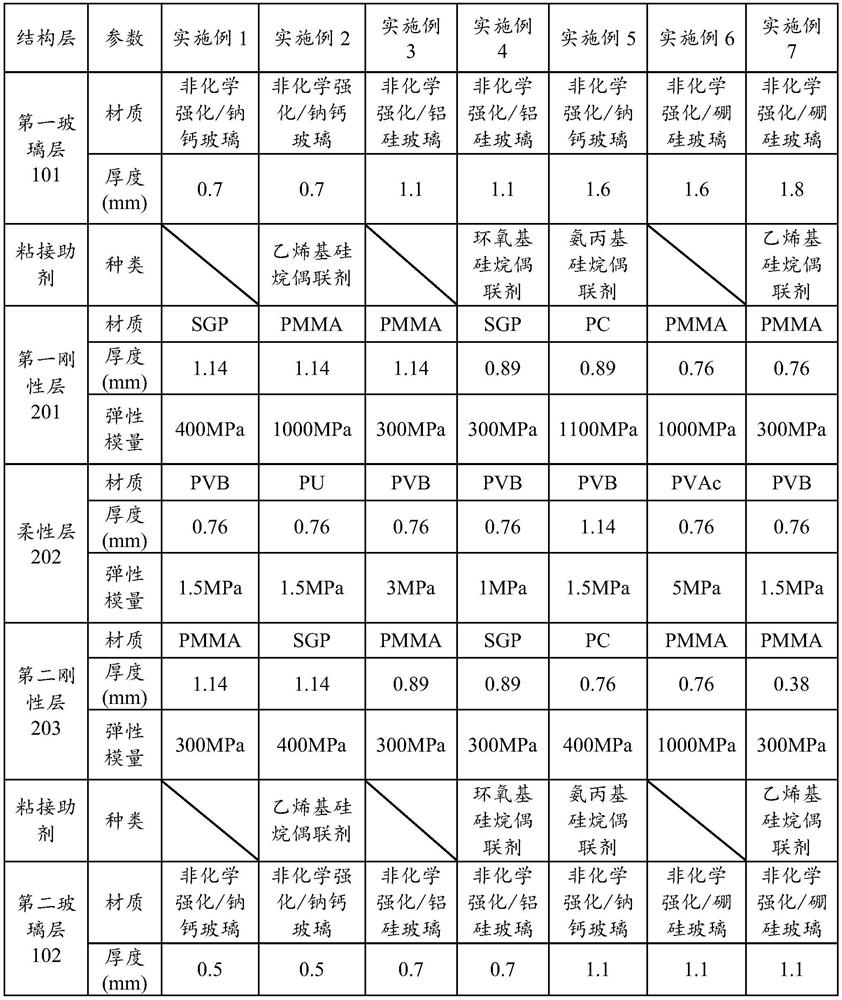

Embodiment 1-7

[0082] The laminated glass of Examples 1-7 was prepared by adopting the preparation method of laminated glass in this application, and the parameters of each layer in the laminated glass of Examples 1-7 are shown in Table 1.

[0083] Table 1 Laminated glass parameter list of Examples 1-7

[0084]

[0085] In order to highlight the beneficial effects of the present application, the following comparative examples are provided.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com