Novel release agent for concrete products and preparation method thereof

A technology of concrete products and release agents, applied in the field of concrete, can solve the problems of interface influence, no technical requirements, corrosion of steel formwork, etc., and achieve the effect of no rust, high finish and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

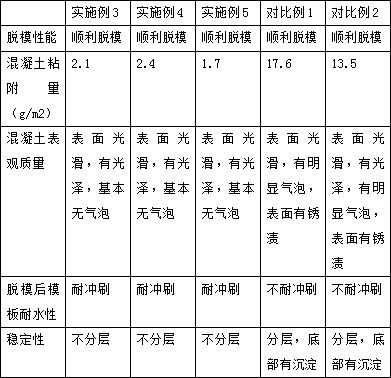

Examples

Embodiment 1

[0036] A kind of mold release agent for novel concrete products, is characterized in that, comprises following components by weight parts:

[0037] White oil: 20 parts;

[0038] Rust inhibitor: 1 part;

[0039] High molecular polymer: 0.5 parts;

[0040] Deionized water: 51 parts;

[0041] Emulsifier: 19 parts;

[0042] Further, the high molecular polymer is cross-linked polyacrylate.

[0043] Further, the rust inhibitor is triethanolamine oleic acid soap.

[0044] Further, the emulsifier is ethoxylated isotridecanol.

[0045] The invention is based on white oil, and uses ethoxylated isotridecanol and cross-linked polyacrylate as the main film-forming substance of the release agent, so that the release agent has strong adhesion, good release effect, and erosion resistance , temperature resistance, can be used many times and so on.

Embodiment 2

[0047] A kind of mold release agent for novel concrete products, is characterized in that, comprises following components by weight parts:

[0048] White oil: 40 parts;

[0049] Rust inhibitor: 3 parts;

[0050] High molecular polymer: 1.0 parts;

[0051] Deionized water: 74.5 parts;

[0052] Emulsifier: 27 parts;

[0053] Further, the high molecular polymer is cross-linked polyacrylate.

[0054] Further, the rust inhibitor is triethanolamine oleic acid soap.

[0055] Further, the emulsifier is sorbitan oleate.

[0056] The invention is based on white oil, uses sorbitan oleate and cross-linked polyacrylate as the main film-forming substance of the release agent, so that the release agent has strong adhesion, good release effect, erosion resistance, and Temperature, can be used many times and so on.

Embodiment 3

[0058] A kind of mold release agent for novel concrete product, comprises following components by weight:

[0059] White oil: 25 parts;

[0060] Rust inhibitor: 1.5 parts;

[0061] High molecular polymer: 0.6 parts;

[0062] Deionized water: 55 parts;

[0063] Emulsifier: 17 parts.

[0064] Further, the emulsifier is a mixture of ethoxylated isotridecanol and sorbitan oleate, the mass ratio of which is 1:1.

[0065] The present invention is based on white oil, uses ethoxylated isotridecanol, sorbitan oleate and cross-linked polyacrylate as the main film-forming substance of the release agent, so that the release agent has strong adhesion, Good demoulding effect, erosion resistance, temperature resistance, can be used many times and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com