Hot-dip galvanized 420MPa-grade low-alloy high-strength steel for automobile and production method thereof

A hot-dip galvanizing and low-alloy technology, which is applied in the field of metallurgical plate production, can solve the problems of unmentioned steel plate microstructure and grain size, poor corrosion resistance, long production cycle, etc., and achieve obvious advantages in product development and corrosion resistance Good performance and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

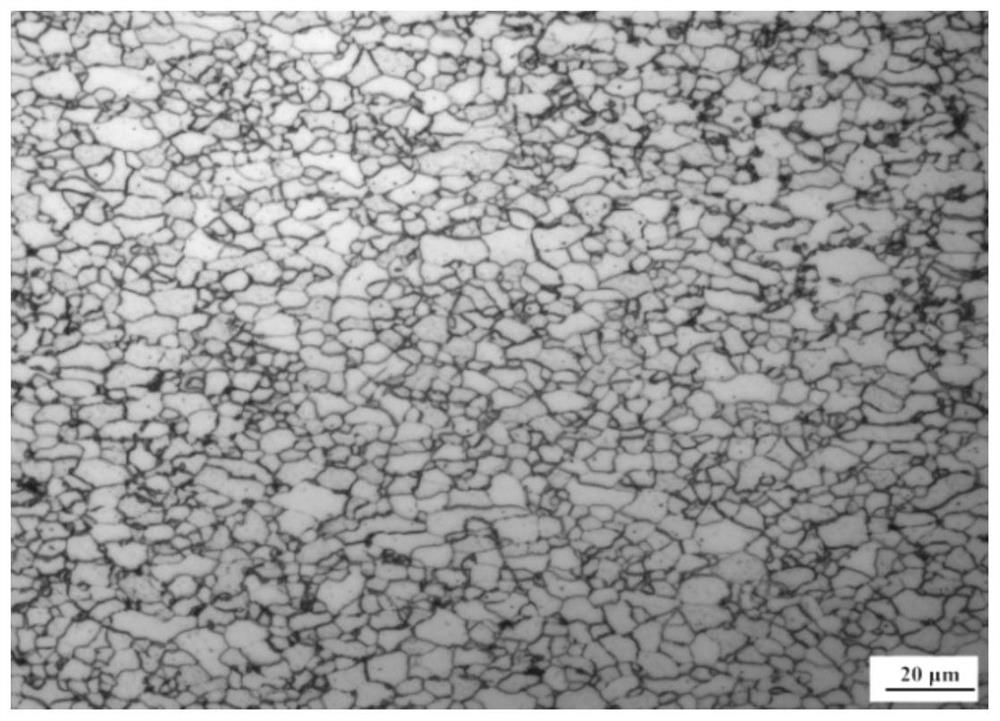

Image

Examples

Embodiment 1

[0026]Desulfurization pretreatment is carried out on the molten iron, the molten iron is decarburized and dephosphorized by top-bottom combined blowing converter smelting to obtain molten steel, argon is blown throughout the converter smelting process, scrap steel is added to the converter, and the tapping temperature of the converter is 1645°C. Then, the molten steel after converter smelting is subjected to LF external refining, and the in-place temperature of refining is ≥1562°C. The LF external refining is subjected to temperature measurement and composition fine-tuning. The chemical composition of the LF external refining casting machine is shown in Table 1. The slab continuous casting superheat degree is 26°C, after which the slab cleaning, slow cooling and continuous casting slab quality inspection are carried out. The heating temperature of the slab is 1236° C., and the heating time is 230 minutes. The heated slab is subjected to high-pressure water dephosphorization. T...

Embodiment 2

[0028] Desulfurization pretreatment is carried out on the molten iron, and the molten iron is decarburized and dephosphorized by top-bottom combined blowing converter smelting to obtain molten steel. The converter smelting process is blown with argon, and scrap steel is added to the converter, and the tapping temperature of the converter is 1650°C. Then, the molten steel after converter smelting is subjected to LF external refining, and the in-place temperature of refining is ≥1565°C. The LF external refining is subjected to temperature measurement and composition fine-tuning. The chemical composition of the LF external refining casting machine is shown in Table 1. The slab continuous casting superheat is 23°C, after which the slab cleaning, slow cooling and continuous casting slab quality inspection are carried out. The heating temperature of the slab is 1232° C., and the heating time is 235 minutes. The heated slab is subjected to high-pressure water dephosphorization. The w...

Embodiment 3

[0030] Desulfurization pretreatment is carried out on the molten iron, and the molten iron is decarburized and dephosphorized by top-bottom combined blowing converter smelting to obtain molten steel. Argon is blown throughout the converter smelting process, scrap steel is added to the converter, and the tapping temperature of the converter is 1656°C. Then, the molten steel after converter smelting is subjected to LF external refining. The temperature of refining in place is ≥1561°C. The LF external refining is subjected to temperature measurement and composition fine-tuning. The chemical composition of the LF external refining casting machine is shown in Table 1. The slab continuous casting superheat is 20°C, after which the slab cleaning, slow cooling and quality inspection of the continuous casting slab are carried out. The heating temperature of the slab is 1225° C., and the heating time is 225 minutes. The heated slab is subjected to high-pressure water dephosphorization. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com