Production method of thin-type needled flannelette and thin-type needled flannelette prepared by production method

A production method and technology of velvet cloth, which is applied in the direction of acupuncture machines, non-woven fabrics, and improved hand-feeling fibers, can solve problems such as high fiber strength requirements, unfavorable fabric elasticity, and fiber filament puncture, so as to avoid puncture Fiber, increased warmth retention, optimized tactile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with embodiment:

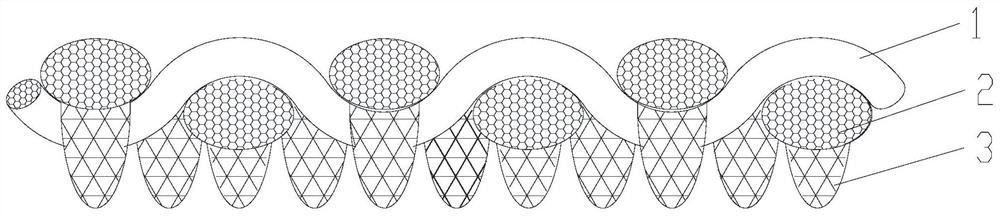

[0019] A method for producing thin velvet cloth, taking woolen woven fabric (interwoven by warp yarn 1 and weft yarn 2) as an example, comprising sequentially boiling the gray cloth, dehydrating, softening, drying once, stitching, and needle punching Velvet layer 3, secondary drying and shearing process treatment; wherein

[0020] The method of boiling the cloth is as follows: immerse the gray cloth in the cloth boiling solution, and cook at a temperature of 60-96°C for 20-60 minutes, and glacial acetic acid is evenly dispersed in the cloth boiling solution;

[0021] The softening method is to immerse the dehydrated gray cloth in the softening solution, remove the gray cloth after dipping, and evenly disperse amino silicone oil and antistatic agent in the softening solution, wherein the content of the antistatic agent is 1.5-3% of the weight of the dipped gray cloth %, the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com