Detachable fabricated type prefabricated floor slab steel bar connecting device, structure and method

A technology for connecting devices and connecting structures, which is applied in the direction of structural elements, building components, building structures, etc., and can solve problems such as difficult to clean, unable to solve the problem of small-diameter steel bar connection, and affect the quality of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

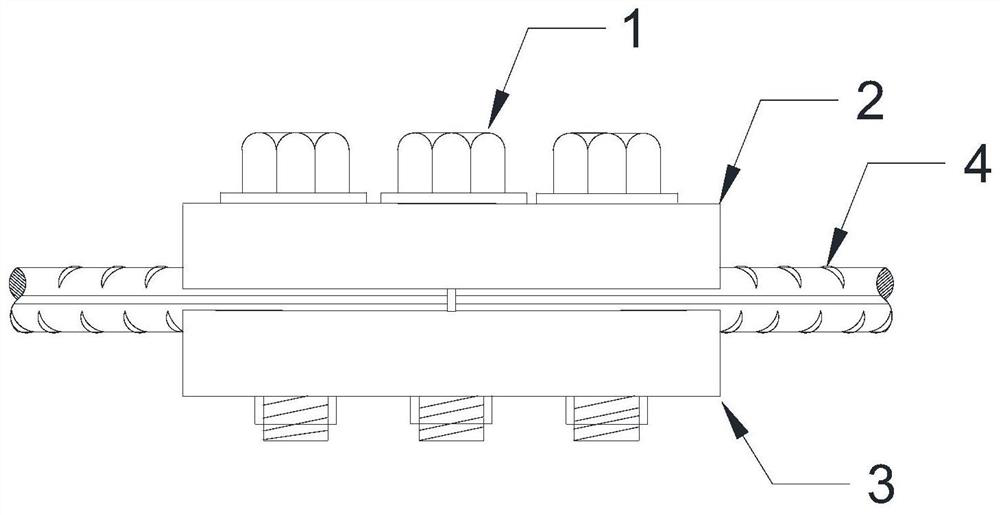

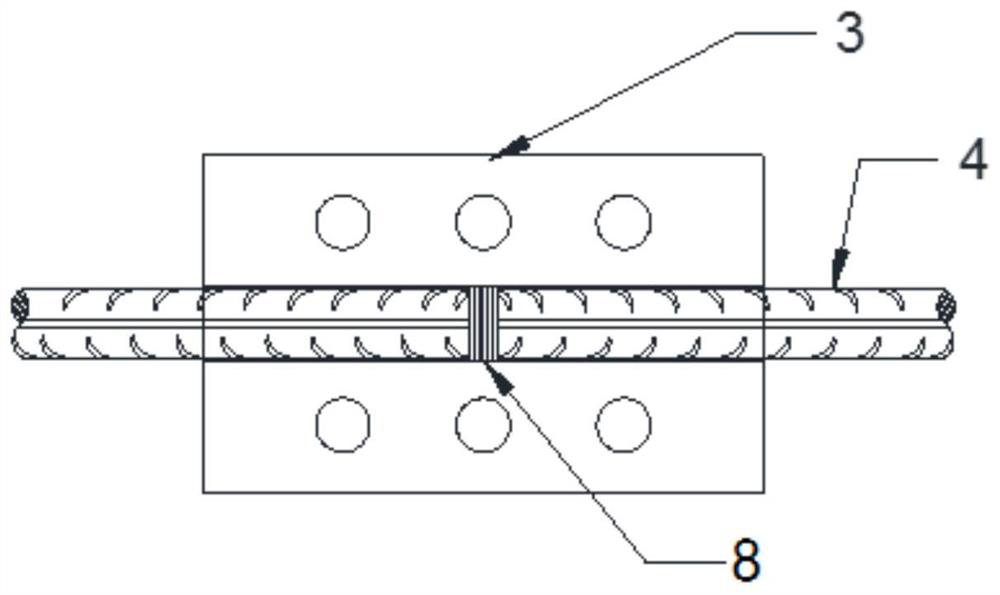

[0030] Such as figure 1 Shown is the detachable assembly type prefabricated floor steel bar connection device according to the present invention, which includes an upper cover 2, a lower cover 3 and connectors.

[0031] Both the bottom surface of the upper cover plate 2 and the top surface of the lower cover plate 3 are flat, and the bottom surface of the upper cover plate 2 and the top surface of the lower cover plate 3 are all provided with through grooves. After the bottom surface of the upper cover plate 2 and the top surface of the lower cover plate 3 are fastened, The upper cover plate 2 and the lower cover plate 3 are connected and fixed by connecting pieces.

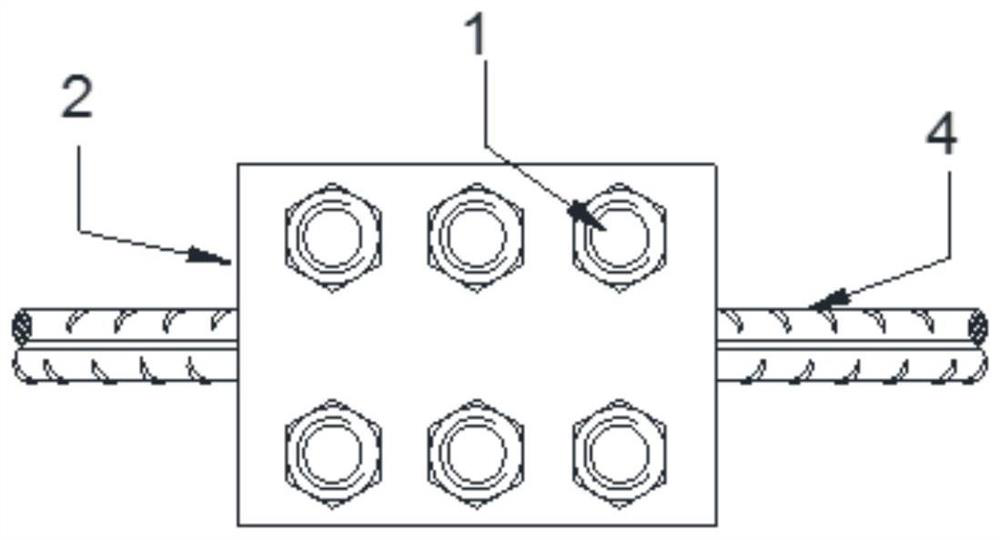

[0032] Such as figure 2 As shown, the connectors of this embodiment adopt high-strength bolts 1, the upper cover plate 2 and the lower cover plate 3 are provided with a plurality of corresponding threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com