Check valve capable of being stopped for high-temperature fluid and valve clack machining equipment of check valve

A high-temperature fluid and processing equipment technology, applied in metal processing equipment, mechanical equipment, milling machine equipment, etc., can solve problems such as low processing efficiency, high safety risks, and increased economic costs, and achieve multi-functionality, improved sealing, and The effect of increasing the reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

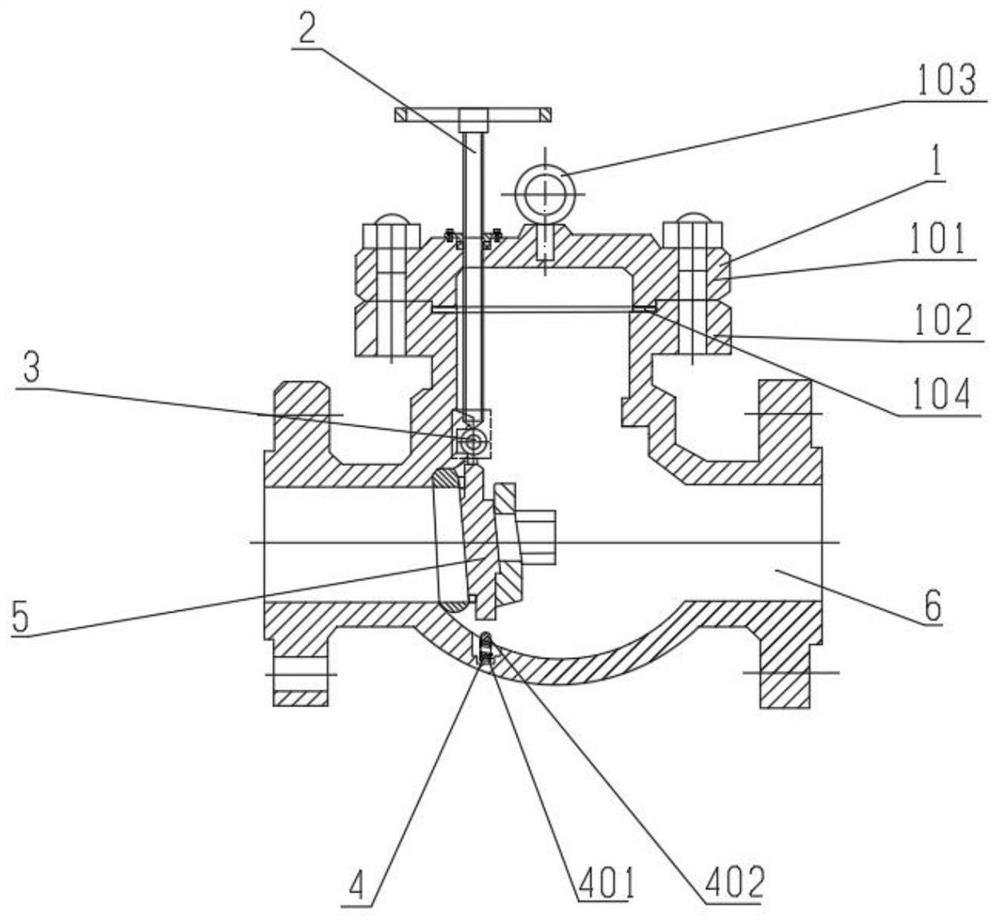

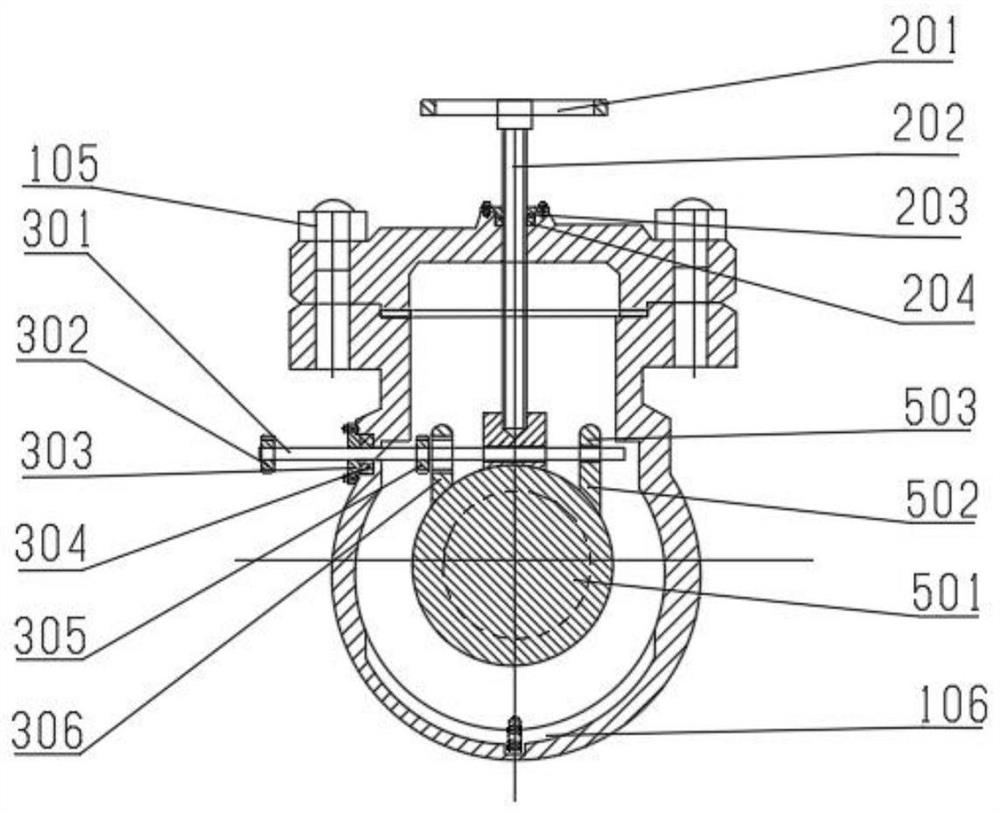

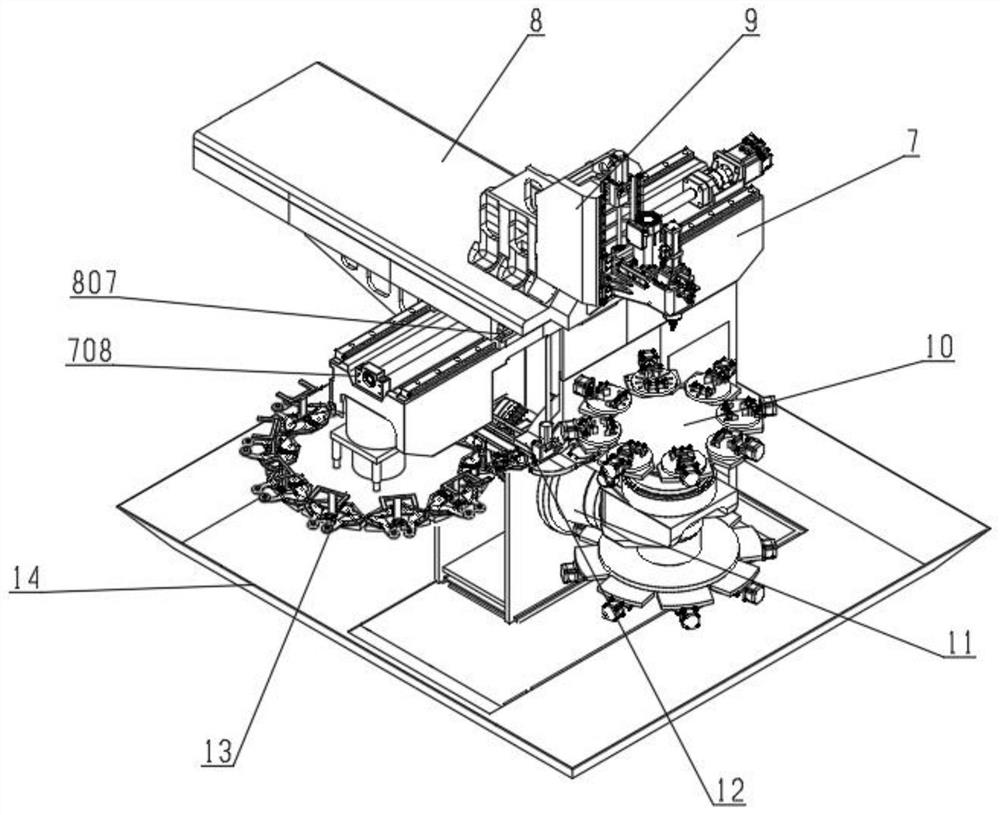

[0056] Such as Figure 1-7 As shown, a cut-off check valve suitable for high-temperature fluids includes a shell part 1, a lower pressure part 2, a rotating part 3, a rebound part 4, a disc 5 and a flow part 6, and the lower end of the lower pressure part 2 runs through the shell part The lower part of the top of 1 is connected to the valve disc 5, the lower pressure part 2 is connected with the top of the shell part 1 by sliding thread, the rotating part 3 is placed in the middle of the shell part 1, and one end of the rotating part 3 passes through the shell part 1 and is rotated and clamped with the valve disc 5. The resilient part 5 is placed at the bottom of the shell part 1 , the valve disc 5 is placed inside the shell part 1 , and the circulation part 6 is a passage through the bottom of the shell part 1 , and the valve disc 5 abuts against one end of the flow part 6 .

[0057] The check valve includes a shell part 1, a pressing part 2, a rotating part 3, a rebound part...

Embodiment 2

[0076] Such as Figure 1-7 As shown, a cut-off check valve suitable for high-temperature fluids includes a shell part 1, a lower pressure part 2, a rotating part 3, a rebound part 4, a disc 5 and a flow part 6, and the lower end of the lower pressure part 2 runs through the shell part The lower part of the top of 1 is connected to the valve disc 5, the lower pressure part 2 is connected with the top of the shell part 1 by sliding thread, the rotating part 3 is placed in the middle of the shell part 1, and one end of the rotating part 3 passes through the shell part 1 and is rotated and clamped with the valve disc 5. The resilient part 5 is placed at the bottom of the shell part 1 , the valve disc 5 is placed inside the shell part 1 , and the circulation part 6 is a passage through the bottom of the shell part 1 , and the valve disc 5 abuts against one end of the flow part 6 .

[0077] The check valve includes a shell part 1, a pressing part 2, a rotating part 3, a rebound part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com