Gas sensitive material for ammonia gas detection, preparation method of gas sensitive material, gas sensitive electrode and sensor

A gas-sensing material, ammonia technology, applied in the direction of material resistance, material analysis, material analysis through electromagnetic means, etc., can solve the problems of destroying the electrical properties of graphene, poor responsiveness and selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

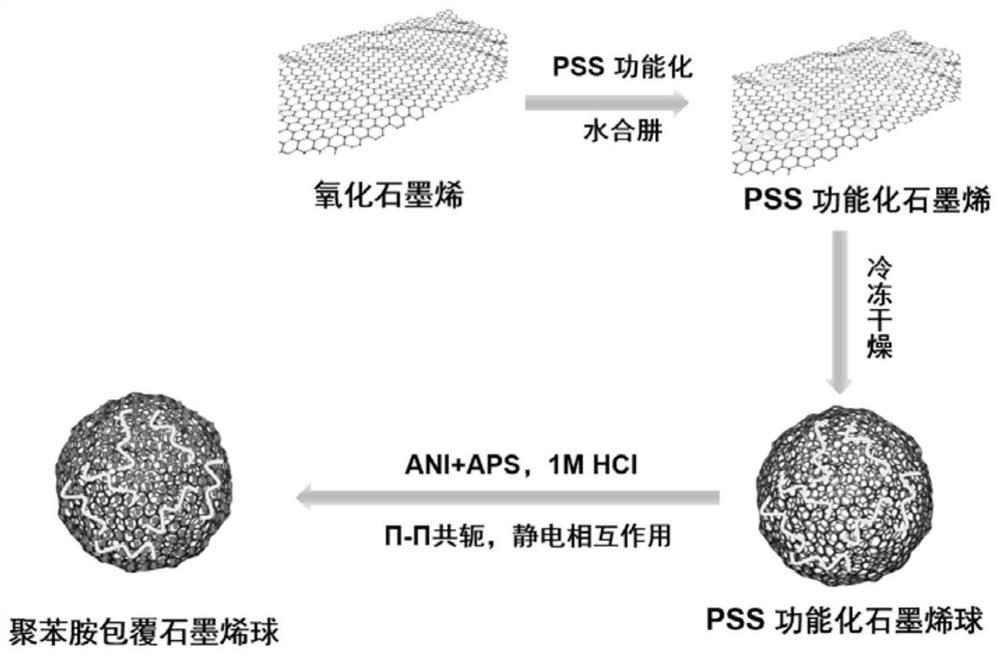

[0031] A gas sensitive material for ammonia detection, such as figure 1 Shown, its preparation method comprises the following steps:

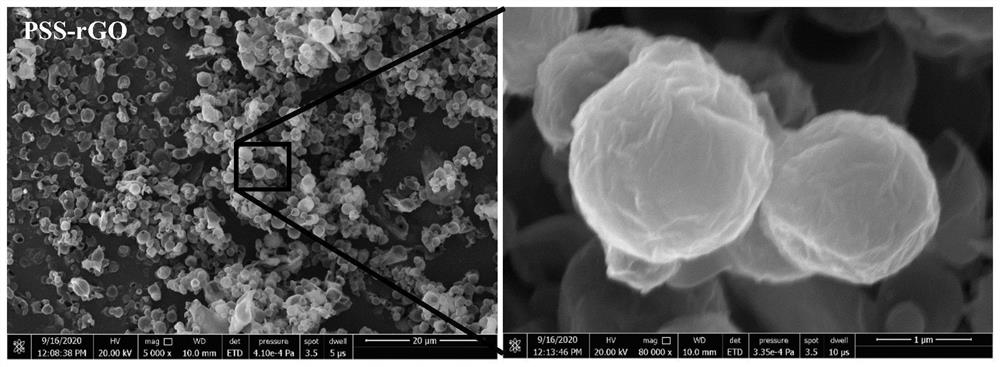

[0032] S1, the polystyrene sodium sulfonate (PSS) of 80mg is dissolved in 10mL deionized water and adds in the one-necked flask of 50mL, adds 4mL graphene oxide dispersion liquid (1mg / mL) in the one-necked flask, obtains mixed liquor; Add 10 mL of hydrazine hydrate (1.12 μL / mL) to the mixture and react at 80 °C for 1 h to obtain PSS functionalized graphene; filter the product to remove excess hydrazine hydrate and free PSS, and then redisperse it in 10 mL of deionized In water, a stable supramolecular assembly dispersion is obtained; then the supramolecular assembly dispersion is subjected to freeze-drying treatment to obtain polystyrene sodium sulfonate-modified reduced graphene microspheres, that is, PSS functionalized graphene microspheres;

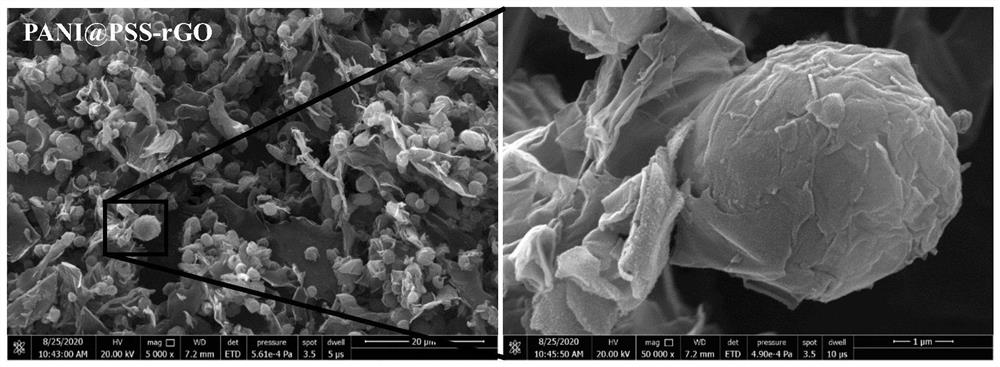

[0033]S2. Disperse the reduced graphene microspheres modified by 10 mg of sodium polystyrene sulfon...

Embodiment 2

[0035] A gas-sensitive material for ammonia detection, the preparation method of which comprises the following steps:

[0036] S1, the polystyrene sodium sulfonate (PSS) of 100mg is dissolved in 10mL deionized water and adds in the one-necked flask of 50mL, adds 4mL graphene oxide dispersion liquid (1mg / mL) in the one-necked flask, obtains mixed liquor; Add 10 mL of hydrazine hydrate (1.12 μL / mL) to the mixture and react at 80 °C for 1 h to obtain PSS functionalized graphene; filter the product to remove excess hydrazine hydrate and free PSS, and then redisperse it in 10 mL of deionized In water, obtain a stable supramolecular assembly dispersion; then freeze-dry the supramolecular assembly dispersion to obtain polystyrene sodium sulfonate-modified reduced graphene microspheres, that is, PSS functionalized graphene microspheres;

[0037] S2, disperse the reduced graphene microspheres modified by sodium polystyrene sulfonate prepared by 10mg step S1 in 90mL sulfuric acid soluti...

Embodiment 3

[0039] A gas-sensitive material for ammonia detection, the preparation method of which comprises the following steps:

[0040] S1, the polystyrene sodium sulfonate (PSS) of 100mg is dissolved in 10mL deionized water and adds in the one-necked flask of 50mL, adds 4mL graphene oxide dispersion liquid (1mg / mL) in the one-necked flask, obtains mixed liquor; Add 10 mL of hydrazine hydrate (1.12 μL / mL) to the mixture and react at 80 °C for 1 h to obtain PSS functionalized graphene; filter the product to remove excess hydrazine hydrate and free PSS, and then redisperse it in 10 mL of deionized In water, obtain a stable supramolecular assembly dispersion; then freeze-dry the supramolecular assembly dispersion to obtain polystyrene sodium sulfonate-modified reduced graphene microspheres, that is, PSS functionalized graphene microspheres;

[0041] S2, disperse the reduced graphene microspheres modified by sodium polystyrene sulfonate prepared by 9 mg of step S1 in 1 mL of sulfuric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com