Industrial equipment management system based on production data

A technology of industrial equipment and management system, applied in the field of industrial equipment management system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

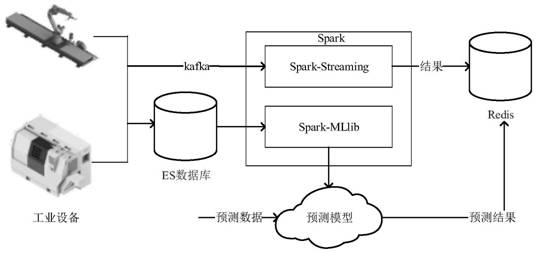

[0036] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] refer to figure 1Software structure, an industrial equipment management system based on production data, based on the decoupling principle of module separation, the system is designed into two parts: a local server deployed in the factory and a cloud server with public network IP. In the cloud core service part, the system uses the SpringBoot framework to design the system structure, including equipment monitoring and predictive maintenance function blocks; uses MySQL and other databases to form the system storage module. The local server includes equipment control module, machine tool and robot data acquisition module and on-site monitoring module. The invention mainly interacts with the database module in the enterprise information system, and simultaneously processes the industrial equipment data collected on site.

[0038] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com