Automobile engine tail gas waste heat thermoelectric conversion control method

A car engine and thermoelectric conversion technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of not being effectively used, not proportional to recycling, and low conversion efficiency, so as to slow down the heat dissipation speed and increase the conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

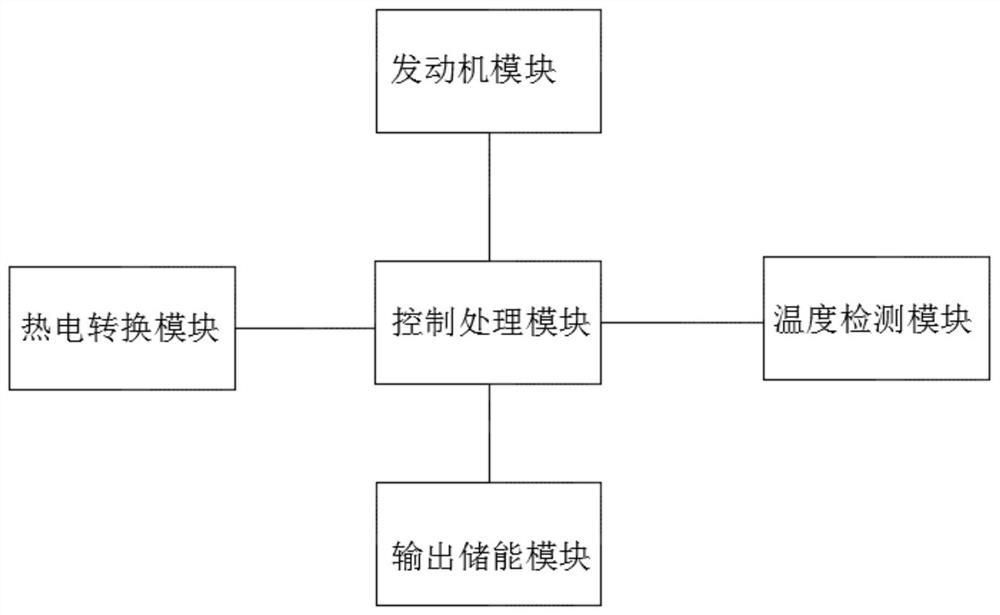

[0029] see Figure 1-2 As shown, the present invention is a thermoelectric conversion control method for waste heat of automobile engine exhaust, including a generator module, a temperature detection module, a thermoelectric power generation module, an output energy storage module and a control processing module, and is characterized in that:

[0030] The generator module, temperature detection module, thermoelectric power generation module and output energy storage module are all connected to the control processing module, the engine module sends the status information of the engine to the control processing module, and the temperature detection module transmits the engine exhaust temperature information to the control processing module, processing The control module controls the start-up of the thermoelectric power generation module and the discharge and storage of the output energy storage module, the processing control module sends conversion control information to the ther...

Embodiment 2

[0037] A control method for a control method of a thermoelectric conversion control method for exhaust heat of an automobile engine, comprising the following steps:

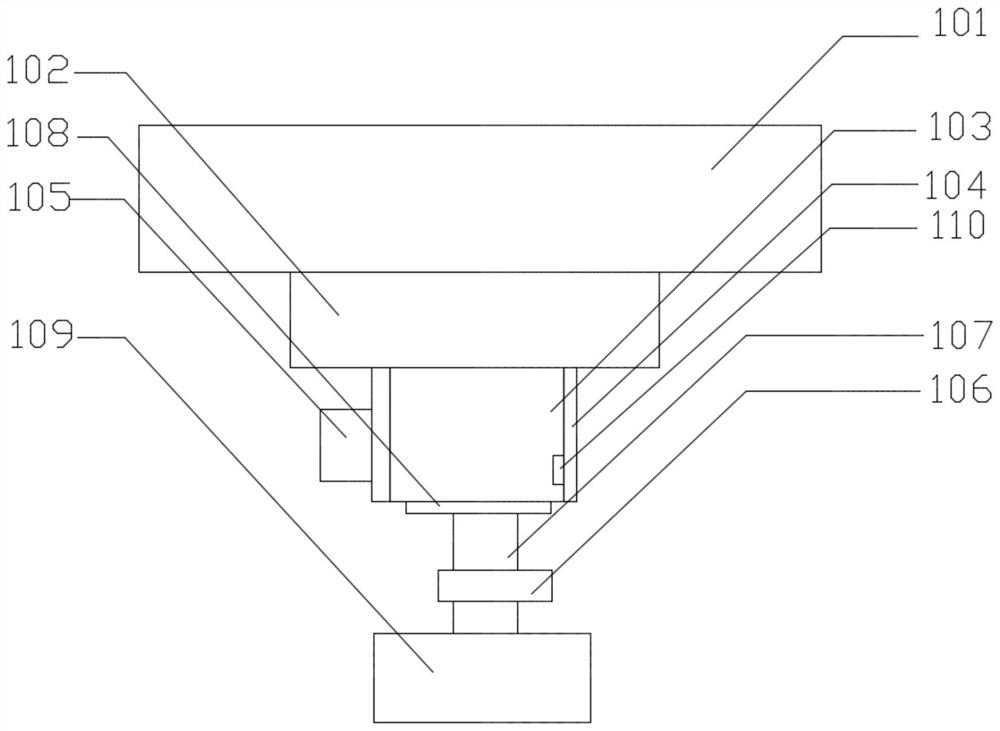

[0038] Step 1: Exhaust gas treatment includes heat detection, heat treatment and heat conversion. The exhaust gas of the automobile can be detected by the temperature detector 110 to know the temperature condition, collected in the heat collecting pipe 103, and the exhaust gas can be pressurized or decompressed through the air pressure regulator 105. Make the exhaust gas state achieve the best effect, the heat insulation layer 104 prevents heat loss, and the waste heat is converted into electricity through the thermoelectric converter 102;

[0039] Step 2: Temperature detection monitors the engine exhaust state in real time. When the temperature reaches the optimum temperature, pressurize through the air pressure regulator 105 to make the conversion environment reach the optimal conversion state; when the temperat...

Embodiment 3

[0045] see Figure 1-2 As shown, the present invention is a method for controlling thermoelectric conversion of waste heat of automobile engine exhaust, wherein the model of the temperature sensor includes but not limited to BRW600-400A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com