Preparation and use method of odor evaluation reference sample block for automotive interior trim part material

A technology for automobile interior parts and material odor, which is applied in the field of preparation of reference samples for evaluation of automobile interior material odor, which can solve problems such as limited practicability, stimulation, human olfactory interference, etc., and achieve good odor representation and stable properties , the effect of large sample inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084]A second aspect of the present invention provides a reference sample of an odor evaluation of an automotive interior material material prepared by the above-described preparation method.

[0085]A third aspect of the invention provides a method of using an odor evaluation reference sample of the automotive interior material material, the usage method comprising:

[0086]When the odor test data of the experimental sample is in the vicinity of the odor qualified line, the odor level cannot be determined, compared with the odor level of the reference sample, using the reference sample as a ruler to determine the final odor level of the experimental sample.

[0087]The fourth aspect of the present invention also provides a method of using the use of the automotive interior material odor evaluation reference sample, the usage method comprising:

[0088]When elective or training new odor evaluator or regularly monitor the horizontal evaluation level, the reference sample is treated according to...

Embodiment 1

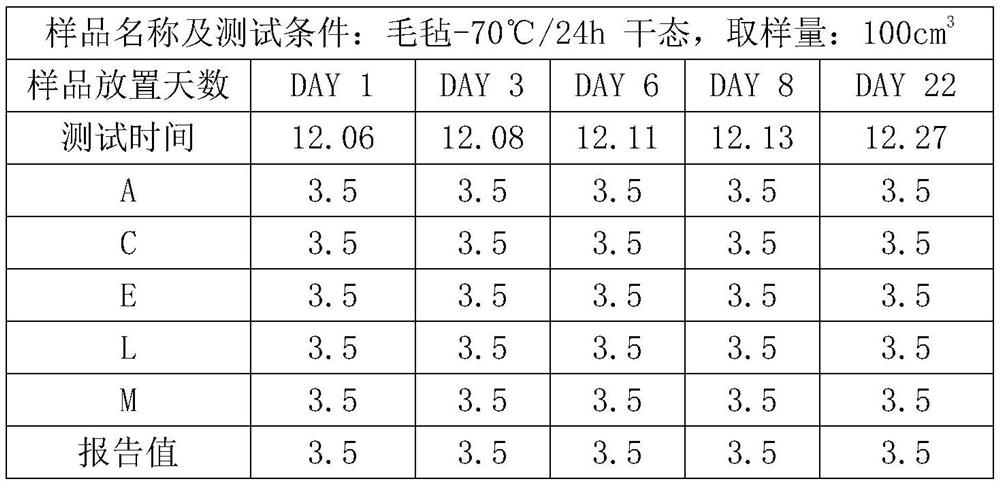

[0105]This example is used to illustrate the preparation method of the odor evaluation of the automotive interior material material.

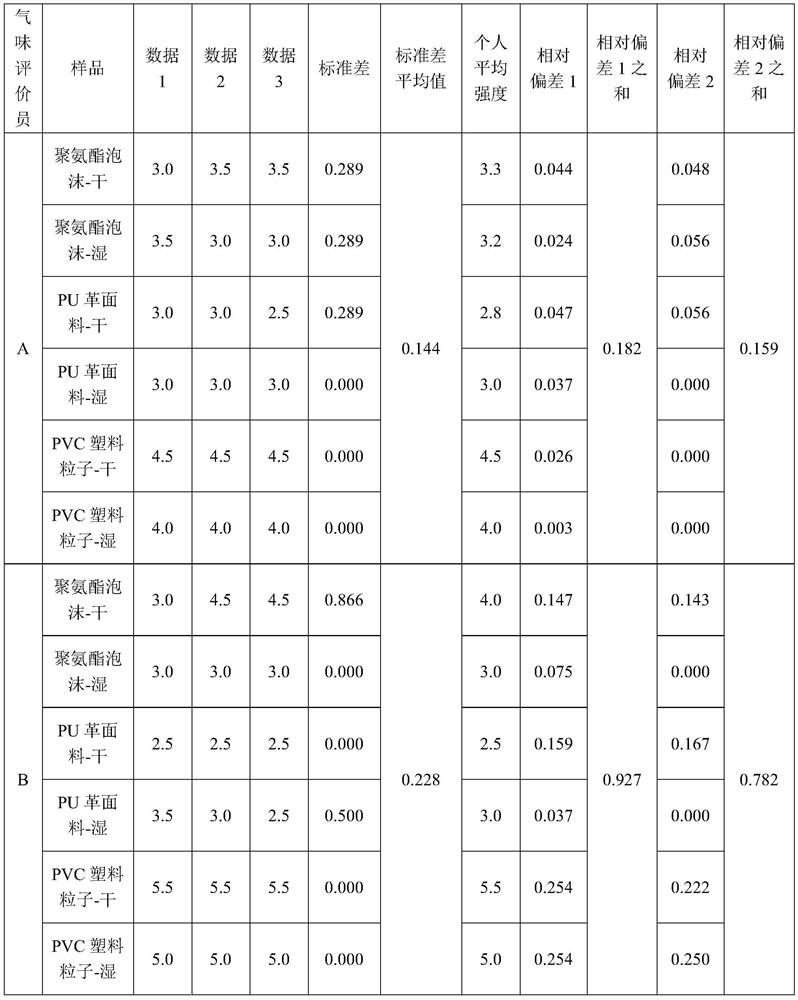

[0106]1) Screening the odor level team

[0107]1 Select the car interior material polyurethane bubble to test, according to the VDA270-2018 standard rating, from the existing odor evaluation team, choose a good daily stability and accuracy, statistical results are shown in Table 3; Experience accuracy, screening off the obvious deviation of odor evaluator;

[0108]2 Inform the odor evaluator, sniffer again, and the memory intensity level again.

[0109]3 minutes and 3 days of gas taste evaluator blind, rating, and investigate stability.

[0110]4 Statistical results, nine selection of accuracy and good stability as a member of the odor level team.

[0111]In order to prevent the instability of the sample, the above steps must be completed within 1 week.

[0112]2) Screening reference sample

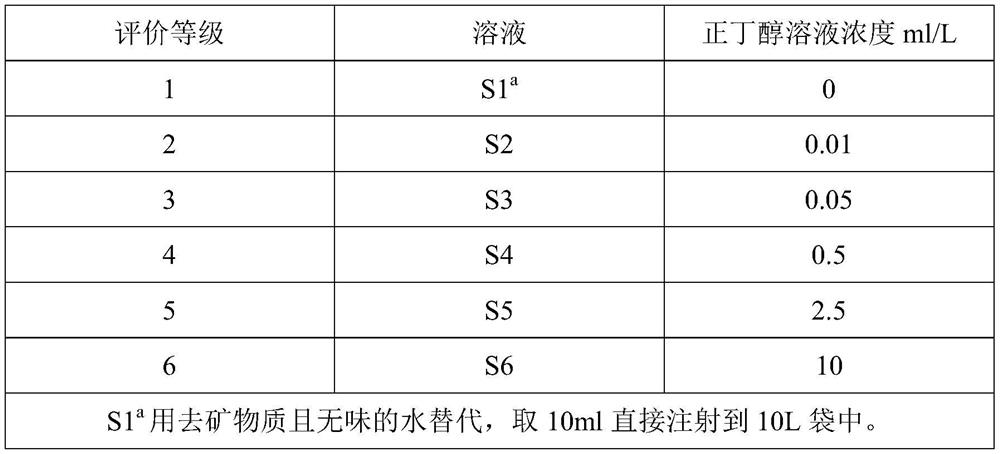

[0113]Sampling and odor tests were performed according to VDA270-2018 standard sam...

Embodiment 2

[0120]This example is used to illustrate the preparation method of the odor evaluation of the automotive interior material material.

[0121]The flavor evaluation reference sample is prepared according to the method of Example 1, which is different, the automotive interior material material is a PU leather fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com