Pulse ablation electrode assembly and pulse ablation catheter

An ablation electrode and ablation catheter technology are applied in the fields of pulse ablation electrode assemblies and pulse ablation catheters, and can solve the problems of poor ablation effect, large workload of linear ablation operations, and poor treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

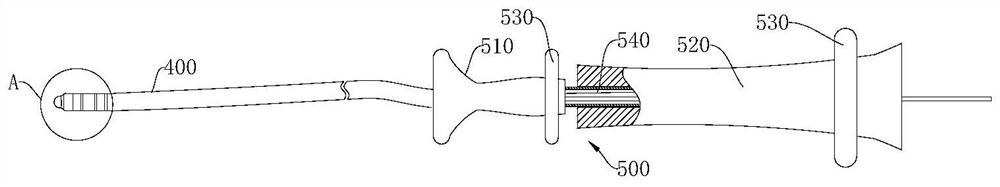

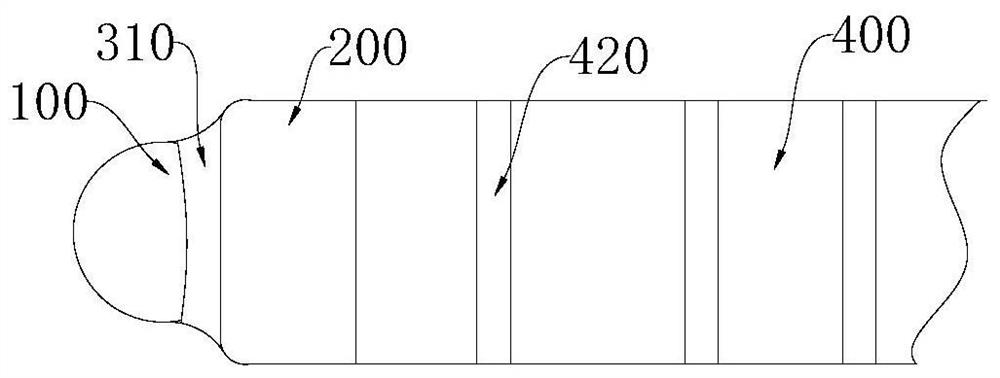

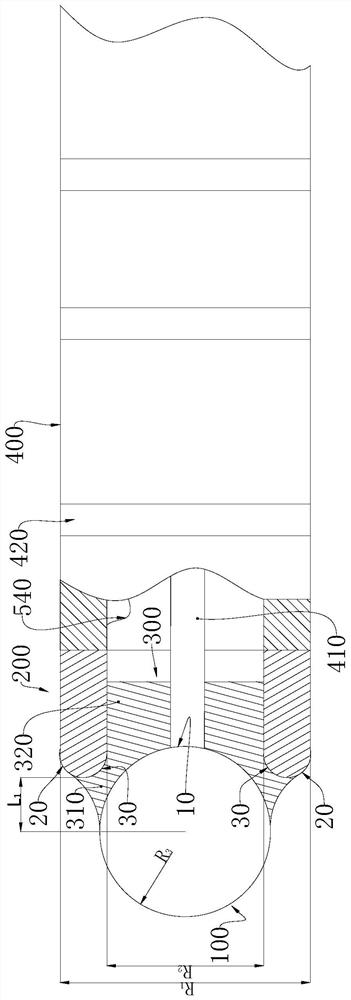

[0028] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

[0029] see Figure 1 to Figure 4, the first embodiment of the electrode assembly for pulse ablation, the electrode assembly for pulse ablation includes a first electrode 100 and a second electrode 200, the opposite ends of the two electrodes are protrusions 10 that gradually shrink, and the protrusions The surface is a curved surface to ensure a smooth transition of the entire electrode end, avoiding the tip effect, and the curved surface can be a positive curvature surface. The surface of the protrusion 10 can be a curved surface of revolution, the generatrix of the curved surface of revolution is a convex curve, and the slope of the convex curve section corresponding to the curved surface on the outer surface of the electrode smoothly transitioning to the top of the protrusion gradually becomes larger, ensuring that the protrusion Shrink effect for cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com