Shifting fork type battery transfer system

A battery and fork-type technology, which is applied in the field of improving the battery structure of the power station, can solve the problems of easy deformation and large volume of the transfer fork, and achieve the effect of improving space utilization, saving upper and lower space, and reducing the risk of battery replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

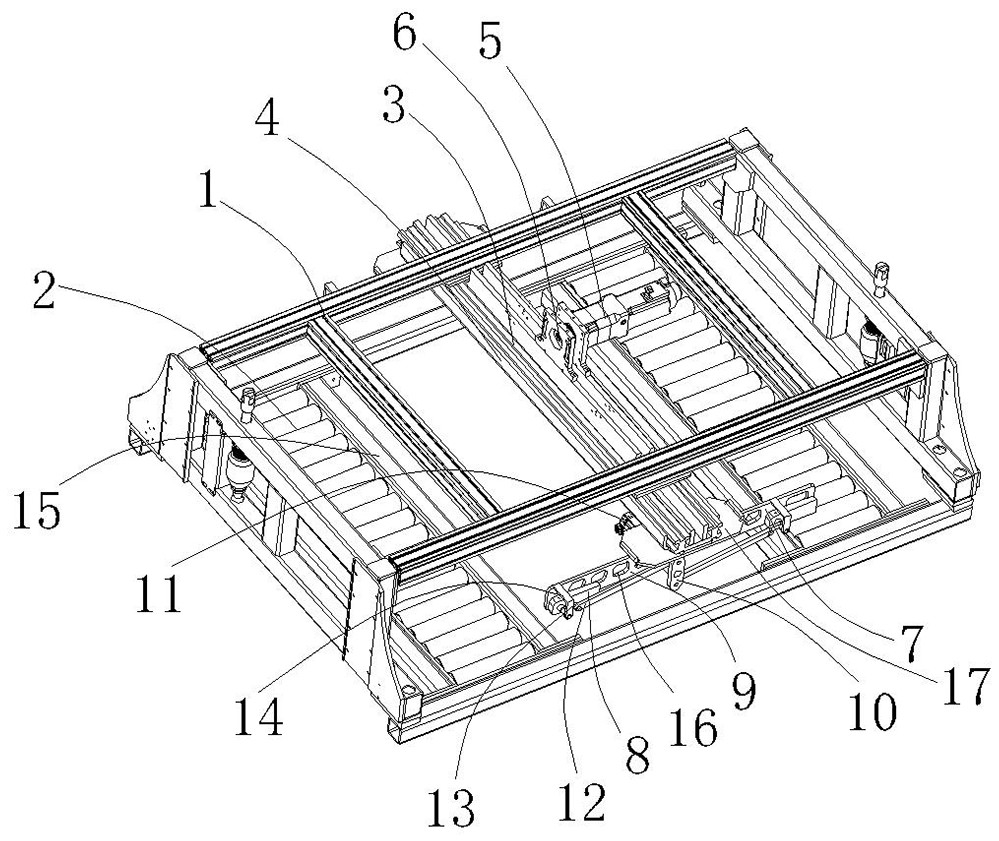

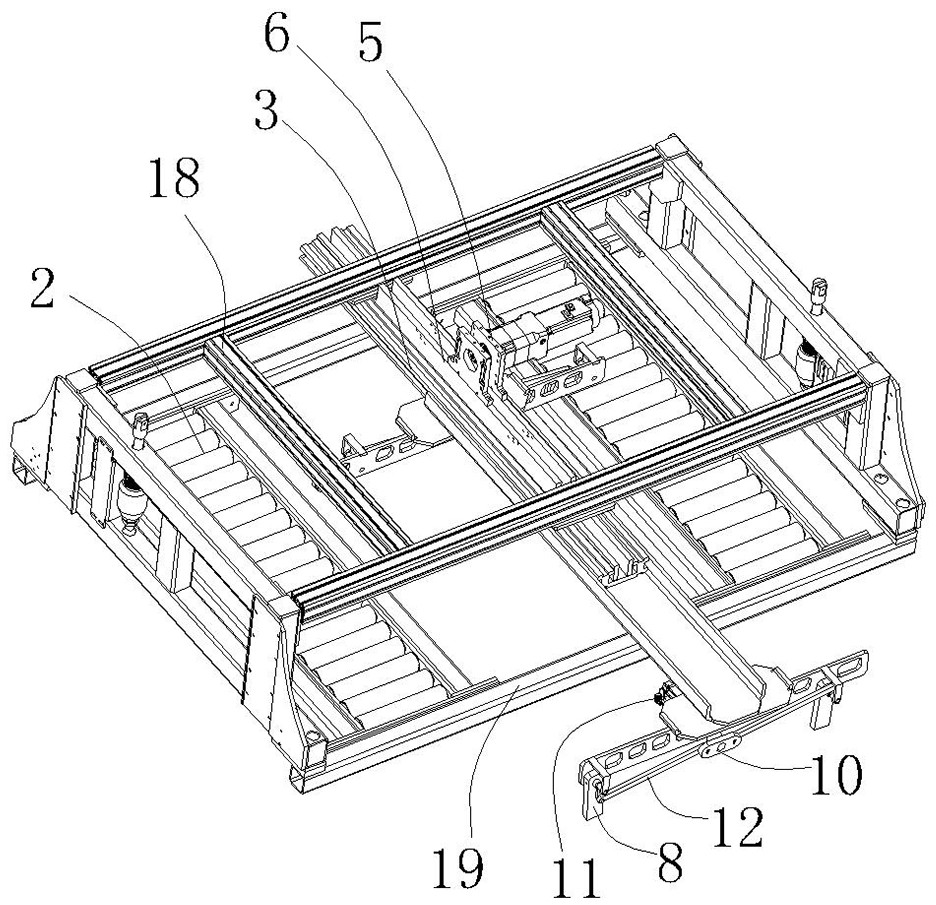

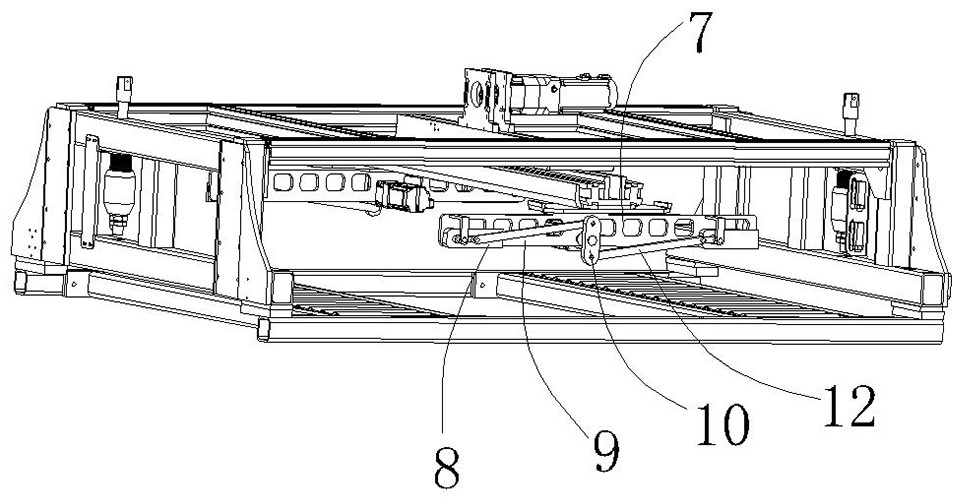

[0024] combined with Figures 1 to 4 , a fork-type battery transfer system, including a transfer frame 1, the bottom of the transfer frame 1 is provided with a roller group 2; the transfer frame 1 is provided with a traversing guide rail 3, and the traversing guide rail 3 is provided with a slide frame 4, and a servo motor 5 is provided above the traverse guide rail 3, and an output gear 6 is provided on the output end of the servo motor 5, and the output gear 6 is engaged with the slide frame 4. The two ends of the carriage 4 are respectively provided with a fork 7, and the fork 7 is provided with a battery buckle 8 and a driving device for driving the battery buckle 8 to snap together.

[0025] The fork 7 is further deepened, the fork 7 includes a fork plate 9, a rotating rod 10 is hinged in the middle of the fork plate 9, and the driving device is a Rotating rod motor 11, each of the two ends of the rotating rod 10 is hinged with a connecting rod 12; each of the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com