Paste type retarder as well as preparation method and application thereof

A retarder and ointment technology, which is applied in the field of ointment retarder and its preparation, can solve the problems of precipitation, retarder thinning, and bacterial contamination, etc., and achieve the effect of extending the shelf life and reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A paste retarder, comprising the following components: 150kg sodium gluconate, 29kg citric acid, 10kg thickener, and 788kg water; wherein, the thickener was purchased from Renqiu Shangkang Chemical Co., Ltd., and the product model is SK -006. The preparation method of retarder comprises the following steps:

[0039] S1, prepare sodium gluconate, citric acid, thickener, iron oxide and water, set aside;

[0040] S2. Add sodium gluconate and iron oxide to water and stir to dissolve sodium gluconate to obtain a mixed solution; mix citric acid and thickener evenly to obtain a mixture;

[0041] S3, slowly adding the mixture to the mixture, and stirring while adding the mixture, to avoid agglomeration during the process;

[0042] S4. After stirring the solution in S3 evenly and standing still for 17 minutes, it becomes a paste, and the retarder of the present application is obtained.

[0043] Apply the retarder to both sides of the mold for preparing the prefabricated compo...

Embodiment 2-17

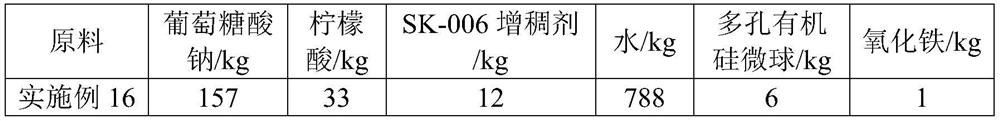

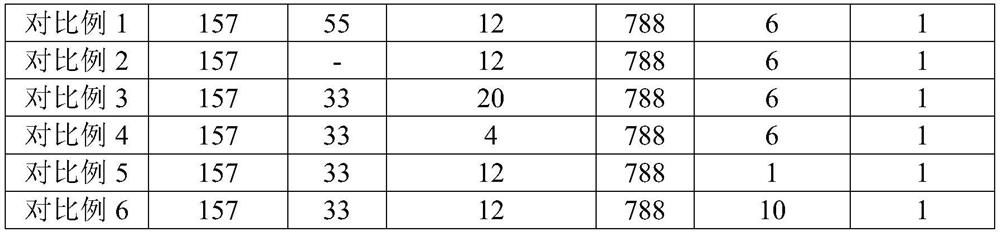

[0045] The difference between Examples 2-17 and Example 1 is that the raw materials and / or the amount of raw materials used to prepare the retarder are different, see Table 1 for details, and the others are the same as in Example 1.

[0046] Table 1

[0047]

[0048] Among them, the thickener with product model LT051 was purchased from Renqiu Litian Chemical Co., Ltd.; porous silicone microspheres were purchased from Dongguan Kemai New Material Co., Ltd., product model KM-9000, with an average particle size of 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com