Toughened scratch-resistant ABS/PET alloy and preparation method thereof

A scratch-resistant, ABS resin technology is applied in the field of toughening and scratch-resistant ABS/PET alloys and their preparation, and can solve the problems of not meeting product use requirements, poor toughness of alloy materials, and general scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

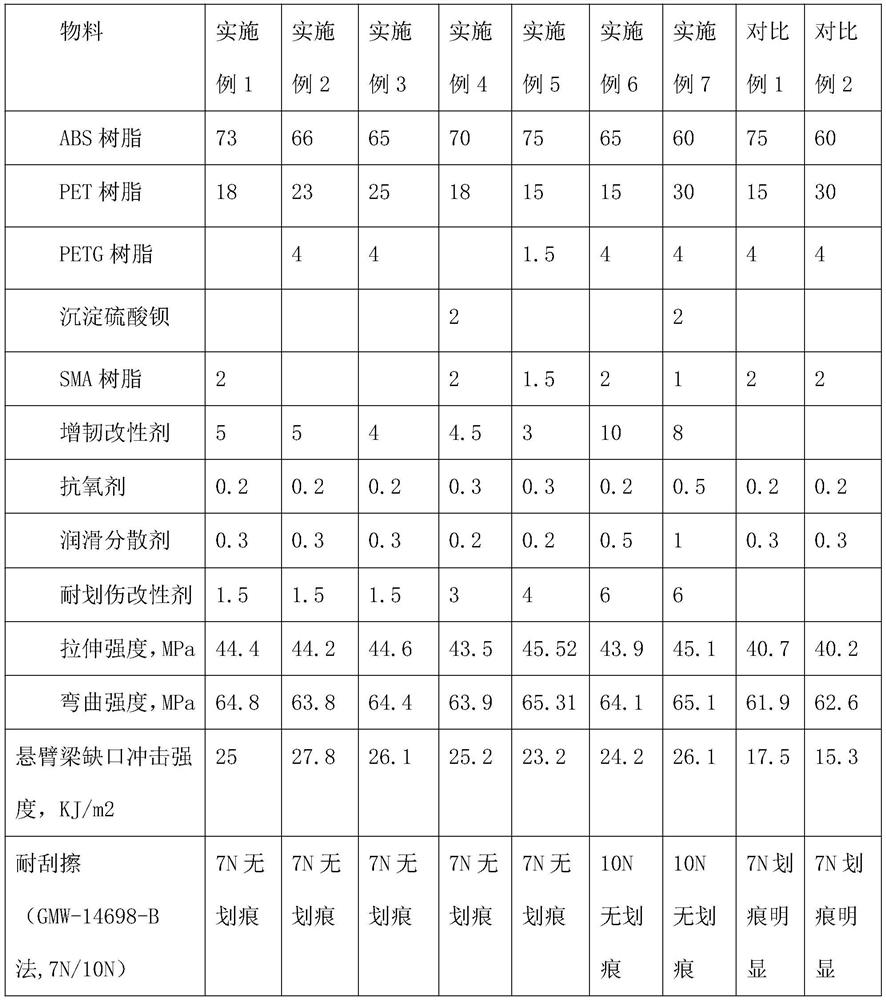

Embodiment 1

[0034] Select 73 parts by weight of ABS resin, 18 parts by weight of PET resin after drying, 2 parts by weight of SMA resin, 1.5 parts by weight of silicone powder, 0.1 parts by weight of antioxidant Y-001, Y-002, 0.3 parts by weight of zinc stearate Parts by weight, 5 parts by weight of silicone rubber masterbatch, each material of the above parts by weight is put into a high-speed mixer according to the process setting. Stirring time is 5 minutes, extruded by twin-screw plastic extruder, body temperature: 210°C, head temperature: 220°C, extruded material is cooled by 20°C water temperature and then pelletized to obtain the present invention.

[0035] Typical performance indicators: tensile strength (ISO 527, 2012, 50mm / min) 44.4Mpa, bending strength (ISO 178, 2012, 2mm / min) 64.8Mpa, notched Izod impact strength (ISO 180, 2008, 23°C, 2mm Injection molding gap) 25.0KJ / m2, five-finger scratching method (five-finger scratching method (GMW-14698-B method, 7N / 10N) without scratche...

Embodiment 2

[0037] Choose 66 parts by weight of ABS resin, 23 parts by weight of PET resin after drying, 4 parts by weight of PETG resin, 1.5 parts by weight of silicone powder, 0.1 parts by weight of antioxidant Y-001, Y-002, zinc stearate, 0.15 parts by weight of erucamide, 5 parts by weight of silicone rubber masterbatch, and 50 ML of white oil. Put the materials in the above parts by weight into a high-speed mixer according to the process settings. Put in the base resin first, and the stirring time is 2 minutes. Slowly add white oil during the stirring process, and then put in other materials, and the stirring time is 2 minutes. Extruded by a twin-screw plastic extruder, the body temperature: 210°C, the head temperature: 220°C, the extruded material is cooled by 20°C water temperature and then pelletized to obtain the present invention.

[0038] Typical performance indicators: tensile strength (ISO 527,2012, 50mm / min) 44.2Mpa, bending strength (ISO 178,2012, 2mm / min) 63.8Mpa, notched ...

Embodiment 3

[0040] Choose 65 parts by weight of ABS resin, 25 parts by weight of PET resin after drying, 4 parts by weight of PETG resin, 1.5 parts by weight of silicone liquid, 0.15 parts by weight of antioxidant Y-001, Y-002, zinc stearate, 0.1 parts by weight of magnesium stearate, 4 parts by weight of silicone rubber masterbatch, and each material of the above parts by weight is put into a high-speed mixer according to the process setting. Put in the base resin first, and the stirring time is 2 minutes. During the stirring process, slowly add the silicone liquid, and then put in other materials, and the stirring time is 3 minutes. Extruded by a twin-screw plastic extruder, the body temperature: 210°C, the head temperature: 220°C, the extruded material is cooled by 20°C water temperature and then pelletized to obtain the present invention.

[0041] Typical performance indicators: tensile strength (ISO 527,2012, 50mm / min) 44.6Mpa, bending strength (ISO 178,2012, 2mm / min) 64.4Mpa, notche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Izod notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com