Efficient fiber ball post-processing device

A processing device and fiber ball technology, which is applied in the field of polyester staple fibers, can solve the problems of inability to ensure the uniformity of short fibers, reduce the probability of antistatic properties, and fall on the transmission line, so as to improve the antistatic efficiency, improve product quality, Stabilize the effect of liquid dip work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

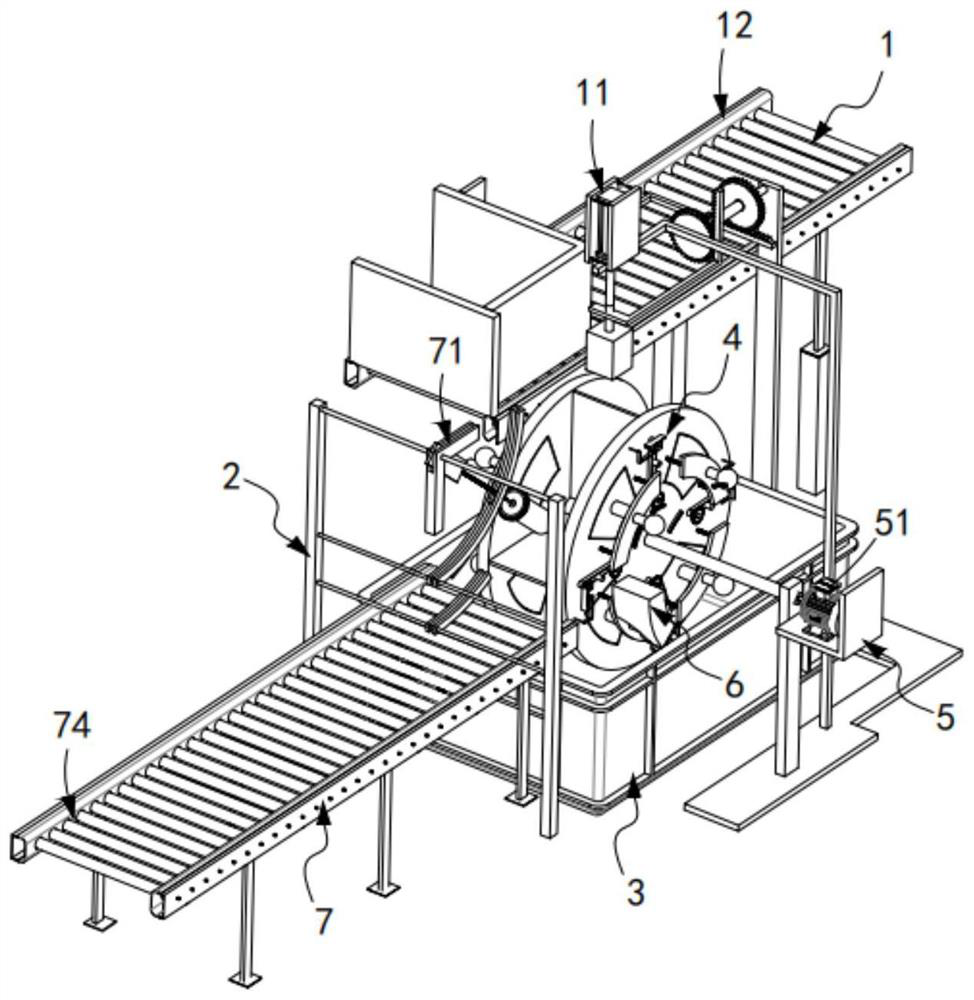

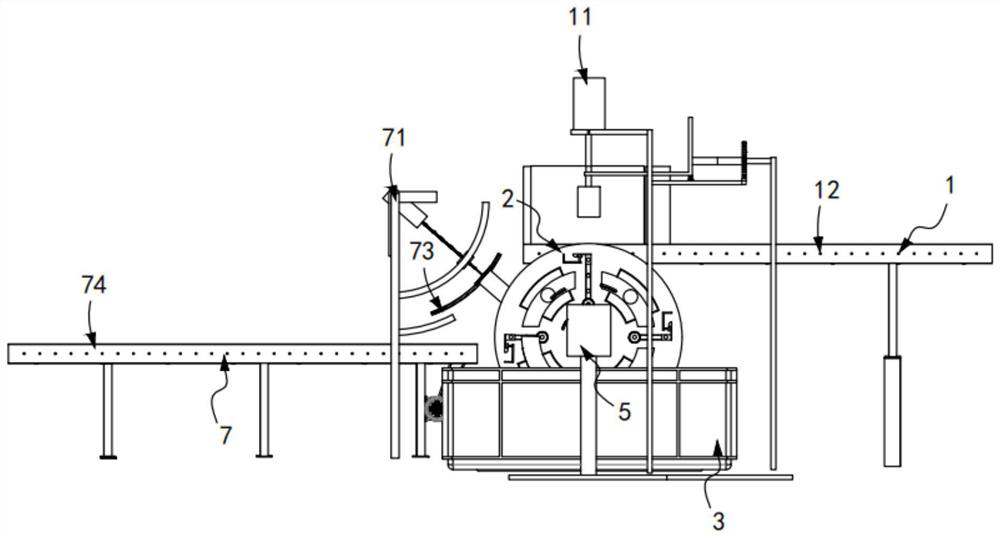

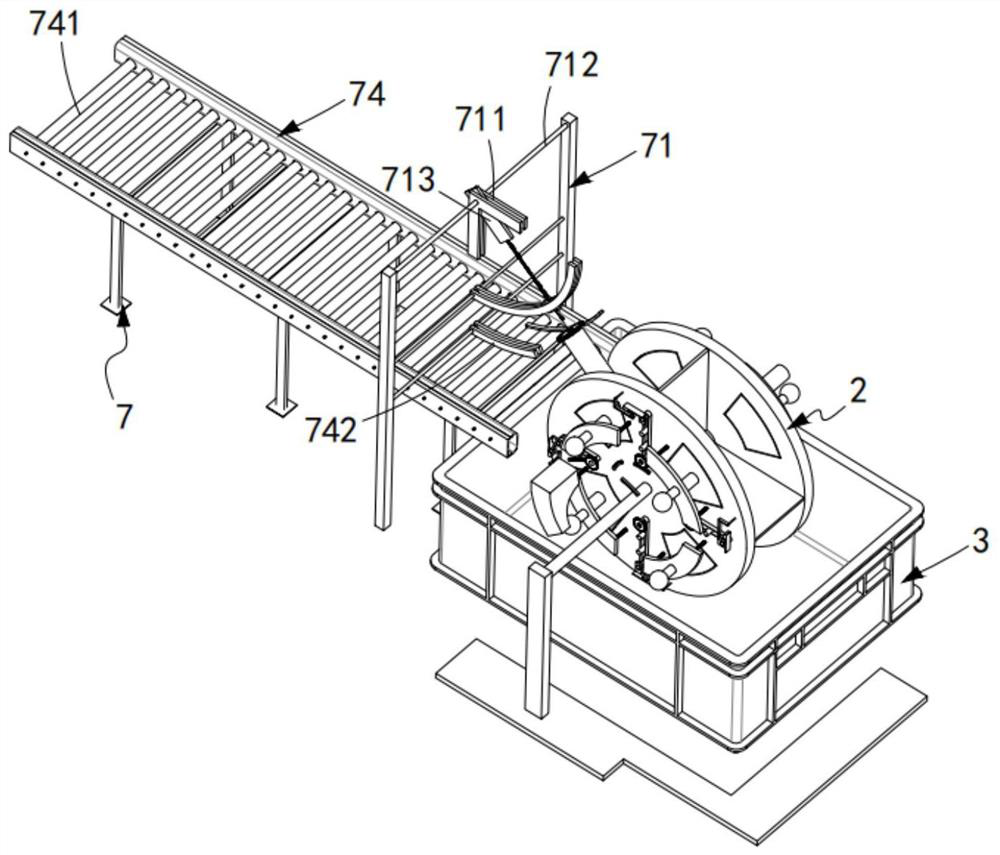

[0078] Such as figure 1 with figure 2 As shown, a high-efficiency fiber ball post-processing device includes an input device 1, an electrostatic treatment device 2 arranged at the output end of the input device 1, and an electrostatic liquid storage box 3 arranged below the electrostatic treatment device 2;

[0079] The electrostatic treatment device 2 includes a station switching mechanism 4, a driving mechanism 5 for driving the station switching mechanism 4 to rotate in a circle, a draining mechanism 6 for draining the destaticized fiber cluster 10, and a For the output mechanism 7 that will complete the output of the fiber cluster after the static electricity removal, the station switching mechanism 4 is sequentially provided with a material receiving station 201, a pretreatment and breaking up station 202, a static electricity removal station 203, and a draining station along its transmission direction. Drying station 204 and slag removal station 205, the draining mecha...

Embodiment 2

[0129] Such as Figure 23 to Figure 24 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0130] further, such as Figure 23 to Figure 24As shown, the intermittent discharge mechanism 12 includes a transmission belt 121, a push plate a122 that moves along the width direction of the transmission belt 121 and is fixedly connected with the driving rack a118, and a stopper that is arranged at the output end of the transmission belt 121 Block 123, the pushing plate a122 is set in a multi-section right-angle plate structure.

[0131] In this embodiment, by setting the push-down mechanism 11 to cooperate with the intermittent discharge mechanism 12, the fiber cluster 10 on the intermittent discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com