A short fiber spinning machine

A short fiber and silk machine technology, which is applied in the direction of short fiber formation, filament production, textiles and papermaking, etc., can solve problems such as discharge and affect the life safety of operators, and achieve the goal of improving air quality, utilization rate and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

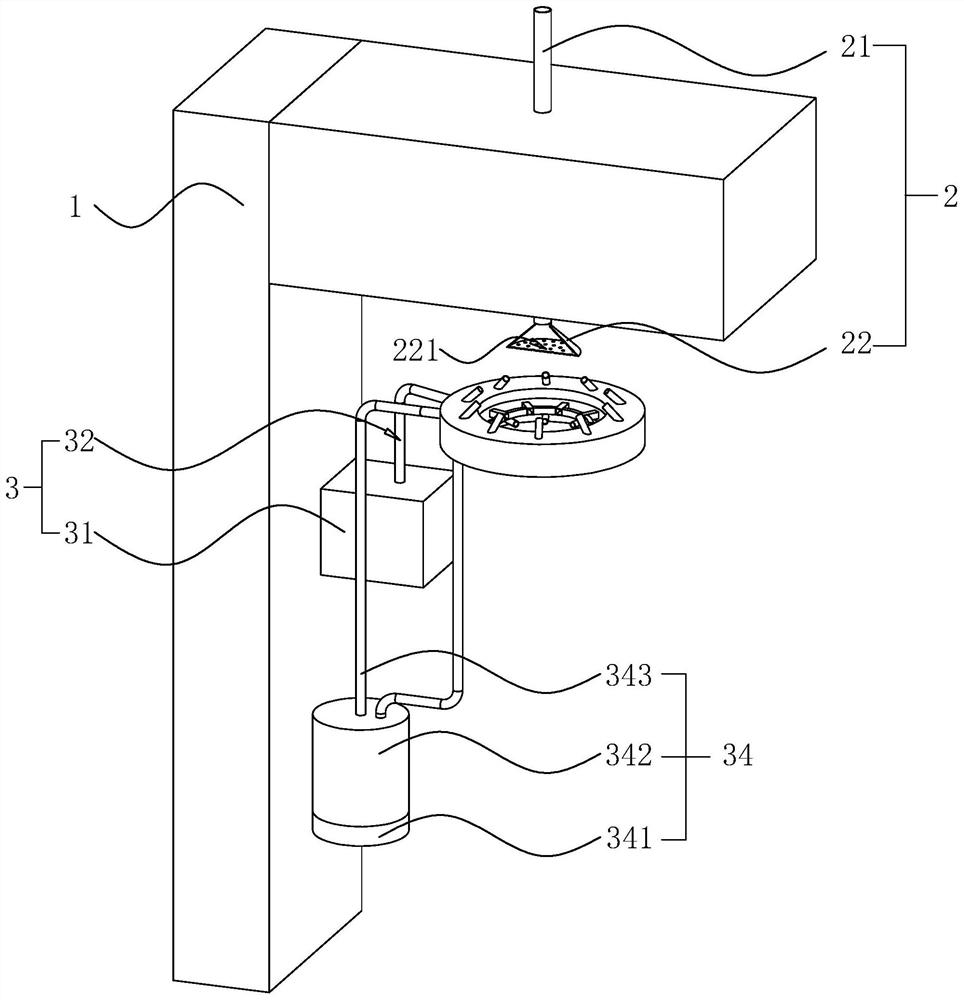

[0037] refer to figure 1 , this embodiment proposes a short fiber spinning machine, including a frame 1, a spinning device 2 and a static elimination device 3, and the spinning device 2 includes a feed pipe 21 and a spinneret 22. The feed pipe 21 is clamped on the frame 1 through a ferrule, and the spinneret 22 is communicated with the bottom end of the feed pipe 21 . The spinneret 22 is conical and hollow inside. The end of the spinneret 22 away from the feed pipe 21 is clamped with a spinneret 221 , and the spinneret 221 is uniformly provided with spinneret holes.

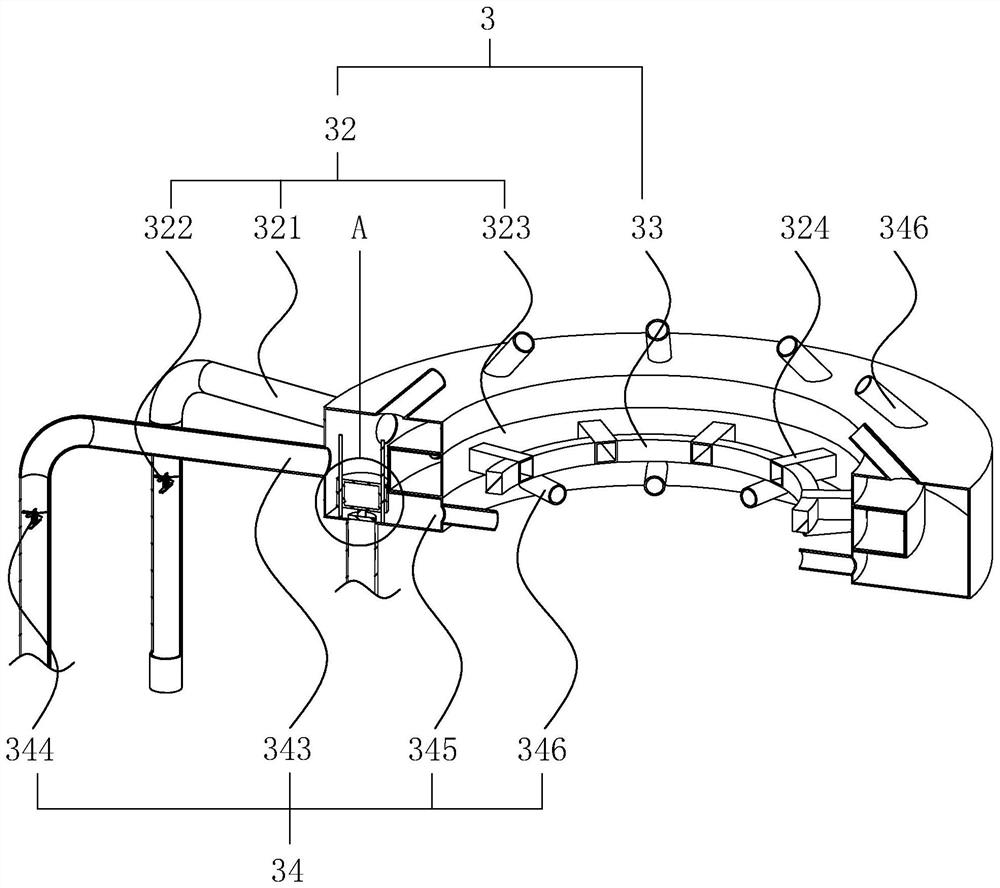

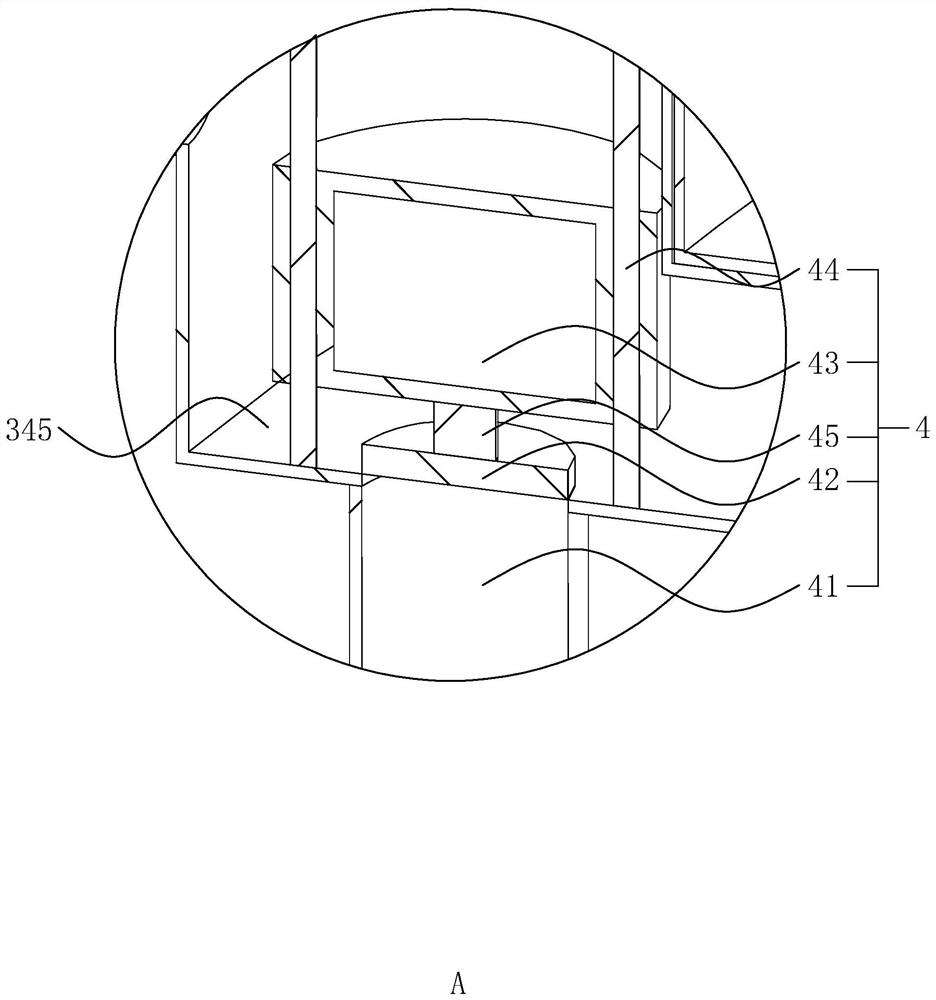

[0038] refer to figure 1 and figure 2 , The static elimination device 3 includes an ion generator 31, a transport mechanism 32 and a magnet 33. The ion generator 31 is fixedly connected to the frame 1 by screws, and the air inlet of the ion generator 31 communicates with the atmosphere. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com